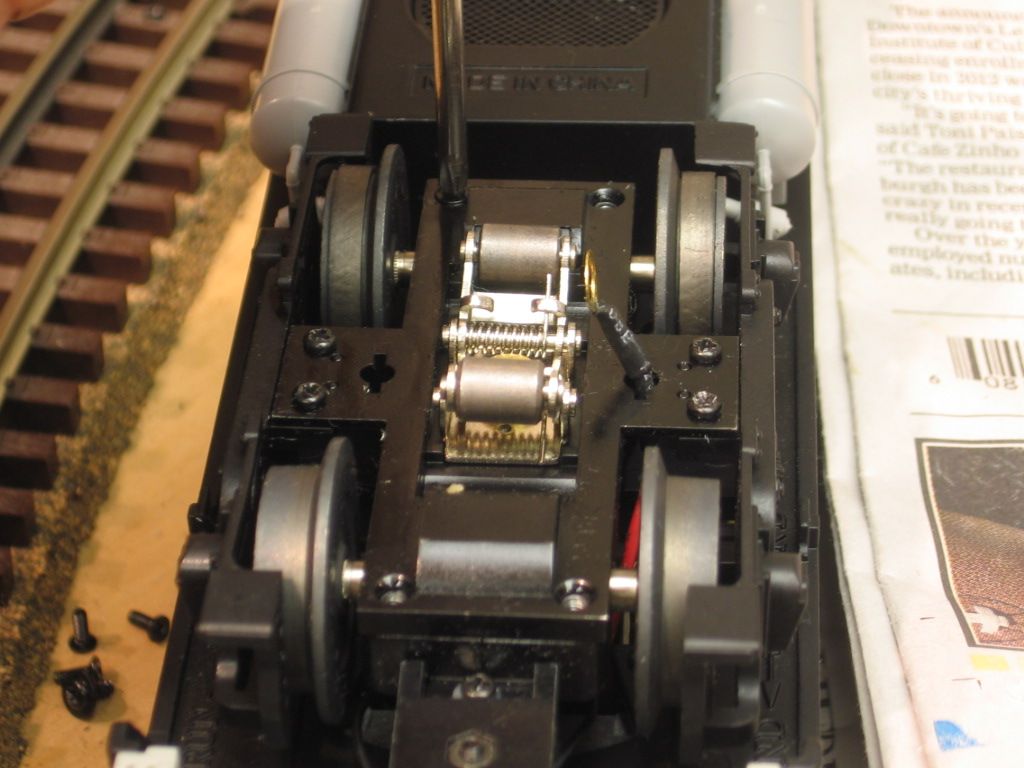

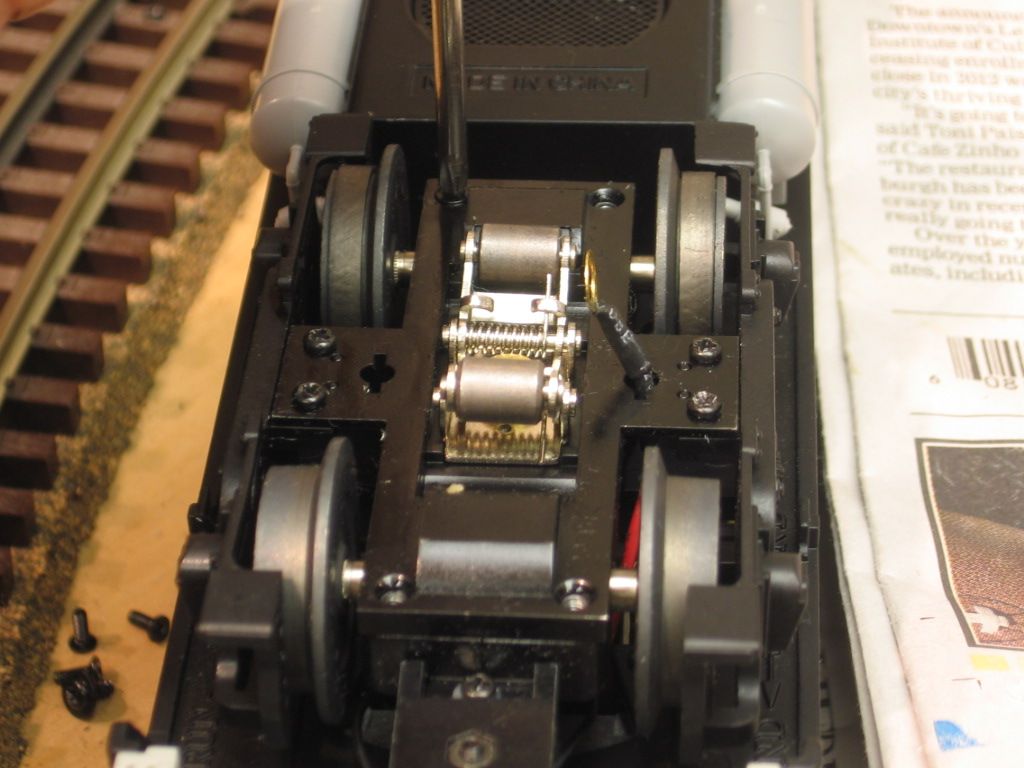

If there is room, some units have double rollers, (4) pick-up per engine.

A stutter or stop at a switch usually involves (2) holes in track power. This large E8 can find hole(s) even though the pickups are 14" apart.

Note the two back to back switches.

The Atlas track dead spot is about 1 5/8"

The Atlas track dead spot is about 1 5/8"

It takes (2) dead spots to cause the stutter or stop. The two holes are about 14" apart but matched up to the Weaver E8 pick-up rollers.

Both Atlas and Ross have details on their website about non-derail wiring of switches, and logical power routing of the small dead rail section positioned in the dead space pictured above. There is also information about the Atlas 6924 switch relay board.

One of several threads on automatic non-derail and power routing. Click on the underlined phrase.

The Atlas track dead spot is about 1 5/8"

The Atlas track dead spot is about 1 5/8"