At the stage in my barn build where I am nearing completion of the roof-n-all that it entails. If you haven't already, stop by and check out the February Build thread for a look at a number of projects currently in the works.

My question is two fold and I hope some of your forumites in the know can share some insight:

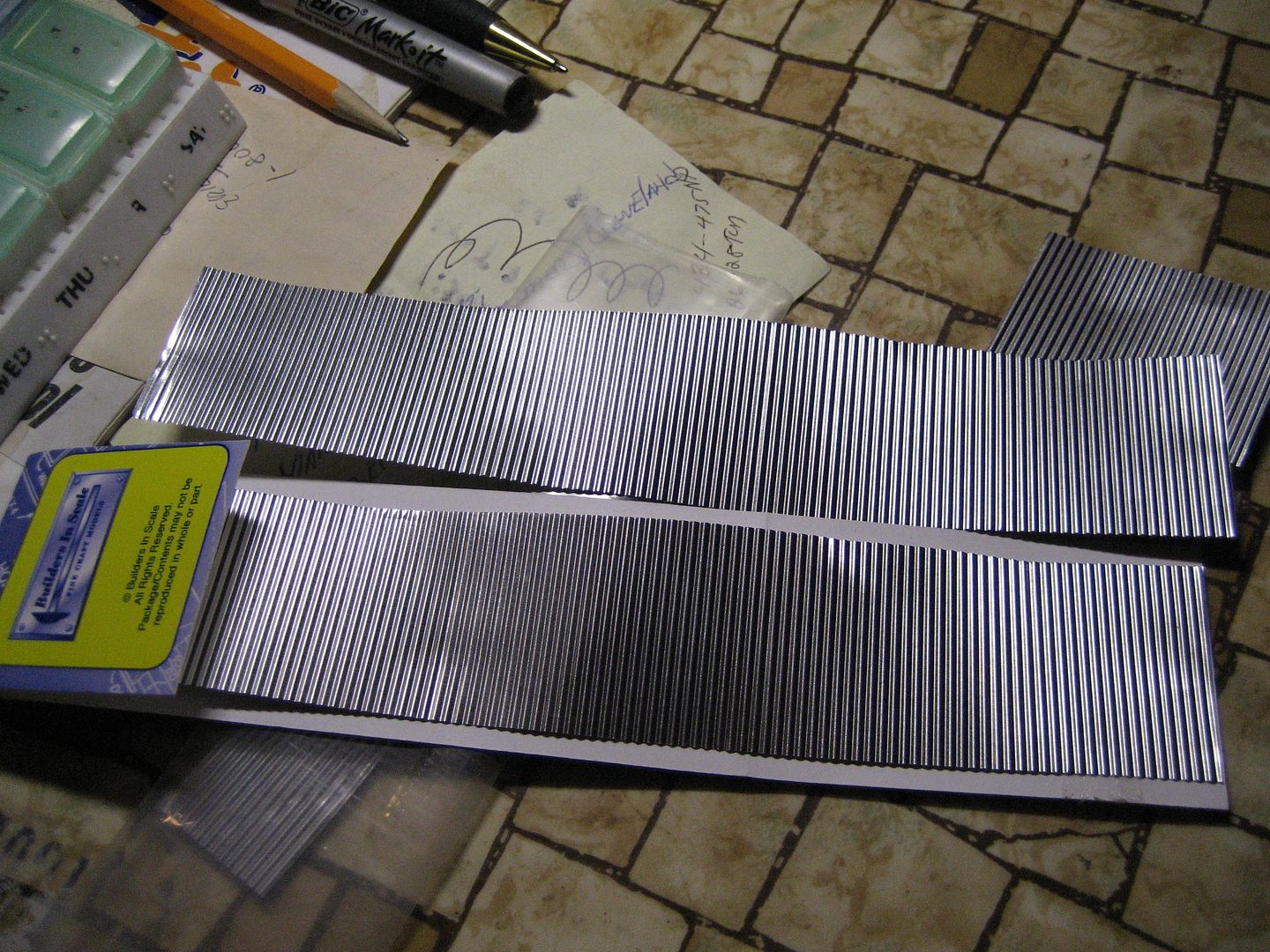

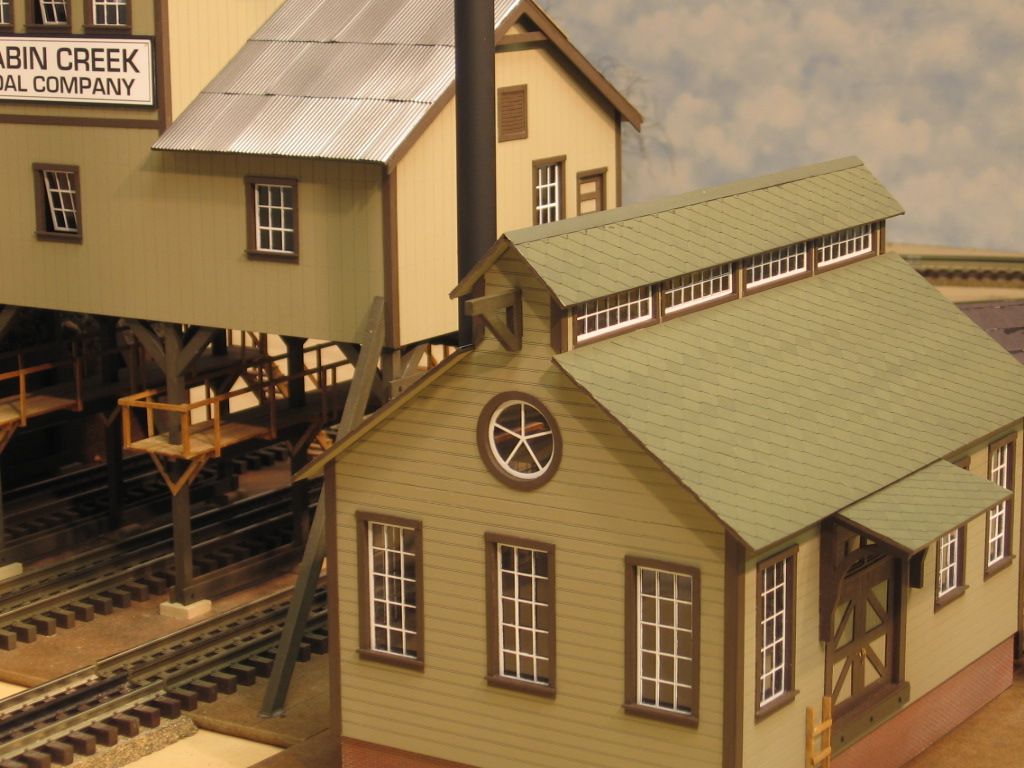

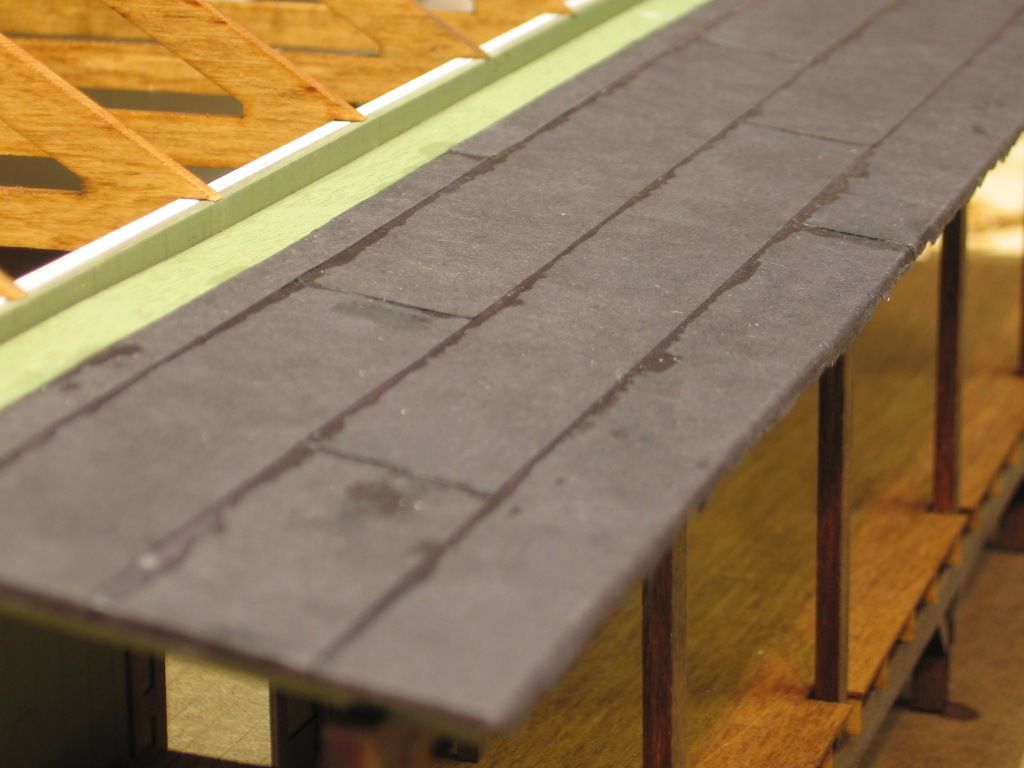

1) What would be considered the most common and prototypical roofing material for barns? In my limited research online I have found both tar paper and corrugated aluminum most often. Is there a preferred material or method when it comes to topping off a barn?

2) As far as tar paper and corrugate go is there a standard width and length used in roofing? As far as I can tell it seems to vary.

Thanks in advance for any help provided in this matter! ![]()