One of my Ross switches works only intermittently. Like only once in a while. I have checked all the wiring and even changed the z1000 machine. Everything checks out. My thought is that it needs some lubrication. In an older post someone recommended Graphite. I was thinking spray silicone. Any thoughts?

Replies sorted oldest to newest

Might have the switch machine screwed down to tight on mounting ties

I removed screws on all track leading up to the switch to free it up. Nothing. The switch itself was not screwed down. The baffling part about this is that the red and green lights come on when I push the buttons on the controller. But nothing happens with the switch. And if I move the switch manually, it seems free to move. All my other Ross switches work great.

Dz 1000 switches have a built in limit switch that disconnects power after the throw. Be sure the switch has completely thrown, move the small peg handle, completely left or right. The three wires also have been know to break off/become disconnected.

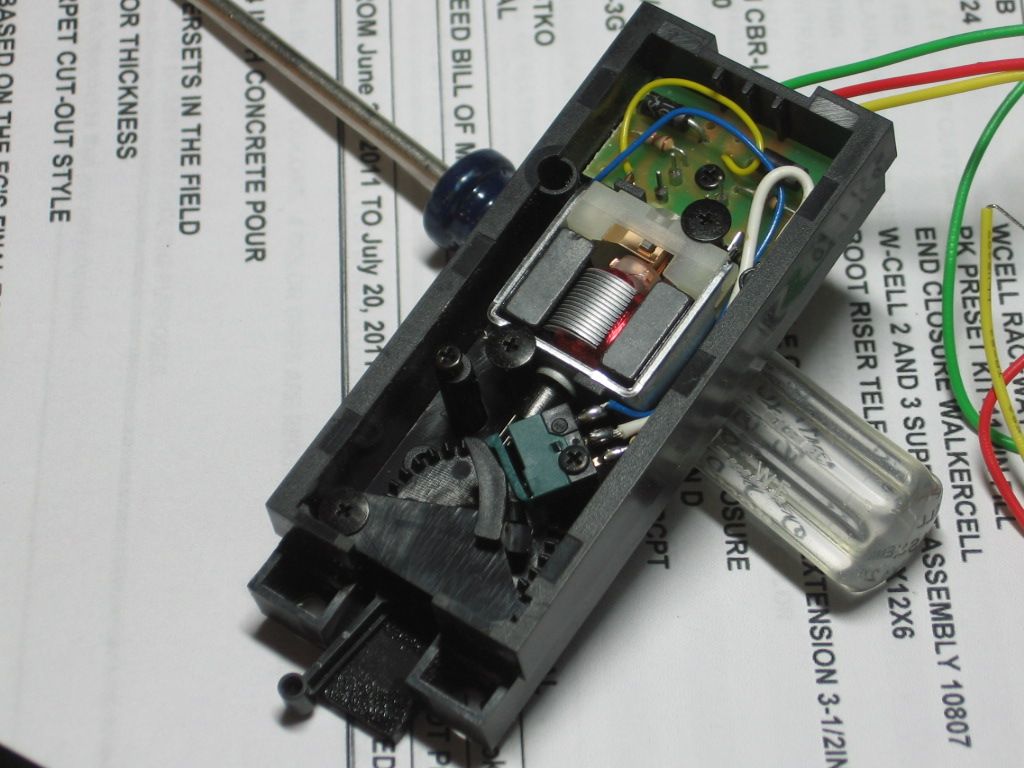

Dark green, lower part of the switch, this picture.

I agree with Tom, I'm a locksmith (don't ask why, had to get away from my Father In Law when my wife decided to move him in with us) and we use a spray lubricant called "Super Lube Sri-Film" to lube the lock cylinders. This stuff is great, it has butane as the carrier and PTFE as the lubricant. This stuff is slick as a whistle and really makes the cylinders turn very smoothly, I also use it on many other items. Can be used on electronics, anything that slides or glides and a ton more uses. It does leave a white residue after the butane gases off (very quickly too), this is the powered teflon , it can be cleaned up with a Q-tip so as not to be unsightly but this stuff works really well. I agree with Tom McGriel about lubing. You can look this stuff up at www.super-lube.com and possibly find a dealer in your area. This doesn't leave an oily film like WD-40 does after it dries off. Don't get me wrong here, I like WD-40, it is great stuff but here in the Arm-pit of Texas it causes problems by attracting dust and stuff which gums up the works on a lot of stuff but it is still a good lubricant too.

Just a thought, if you can find it, you might give it a try, it comes with a straw for better placement of the dry-film, give it a try, you may find many more uses for it around the house.

Hope this helps,

I don't think it's wires, since I have already changed the switch machine. Mike, I checked out the switch to make sure that it is thrown all the way. Now it fails to operate all the time. If I switch it manually, the controller does operate it once to bring it back to curved position. I think I'll remove the switch and try it on my work bench.

The pinion gear on the tiny motor may have come loose or fallen off the shaft. If so, use CA adhesive to reinstall. This happens frequently.

Just a thought after reading this. If you changed out the switch motor and it still did the same thing could the wires leading to the switch be getting sporadic current or maybe the the switch controller has a problem.....Paul

Update: The switch motor works fine on my work bench with another switch. When I take that same switch motor and install it on the layout switch, it works about every 4th try.

Paul: The switch motor can't be defective, if it works on my bench. Must be the wires leading to the switch, but I've really checked them out already.

I've changed out the controller. Checked out all the wires again and their connections. Still works about 1 out of 4 times. So frustrating.

OK. I've finally figured out what the problem is. However, now I can't solve it. Mike, you were correct. The "peg handle" you mentioned doesn't go far enough. The switch machine works fine, but the switch does not permit the peg handle to go far enough. It looks as though the switch is too short a throw distance for the switch machine. So the wire linkage piece doesn't have far enough to travel before the switch is moved all the way. Does this make sense. Now how do I fix it?

There were a couple of different spring options that came with the DZ 1000 switch motors, used to connect the switch motor to the switch. You may want to check with Dennis Zander about the small spring connectors.

Run the switch machines at 14 VAC. 10 volts is too low. Also disconnect the switch machine from the switch and remove the spring connecting the machine to the switch throw. Now try the switch. Does it work? If so, something is either binding the operation, or the throw is too short on the switch.

bruce

I have found that I need to raise the voltage. To make the 2500 machine switch needs a little higher voltage than normal especially. If you have a bunch on the same circuit. I think what j. Mitts said is also a good soulition. Try them both.

Thanks for all your suggestions. I tried bumping up the voltage. No better. I spoke with RCS. He said to send it back and they would replace it. Thought it was probably a faulty contact on the slide bar. I've put in too much time on this switch already and have given up. I'll send it in.

Do you have the switch controller mounted on a conductive surface like a metal plate ? If so, that could be the issue.

Nope. But thanks.

You saved yourself a lot of headache time by calling Steve. Problem solved.