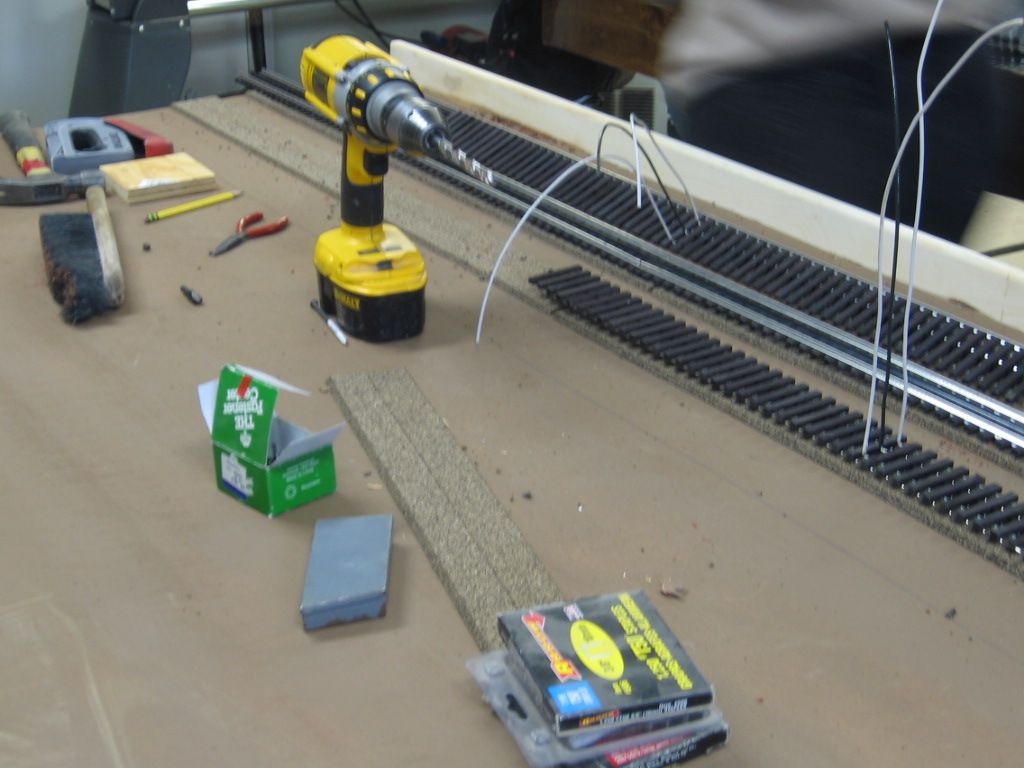

Gunrunnerjohn talked me into soldering wire connections to power my track. This is a 16x17 layout with Gargraves track and Ross turnouts, divided into 8 electrical blocks. Operation is DCS and TMCC through DCS using 3 TIUs with all outputs fixed, in SUPER mode. No conventional operation and no Legacy.

I hadn't wanted to solder the track and was looking for some way to attach wires from the TIUs to the track without soldering. GRJ suggested that everything would be more reliable if I just soldered the connections. I believe he is right and off I went with Weller's big-butt 240 watt soldering gun.

It has all worked out pretty well EXCEPT that some sections of Gargraves track will not take solder no matter what I do. Oddly, this only occurs on the shiny outer rails. The black center rail ALWAYS takes solder (so far). I grind a clean area along the base of the rail, tin the wire and then tin the clean area of the rail. Then I apply heat and solder and 85% of the time, this all goes smoothly and I march on.

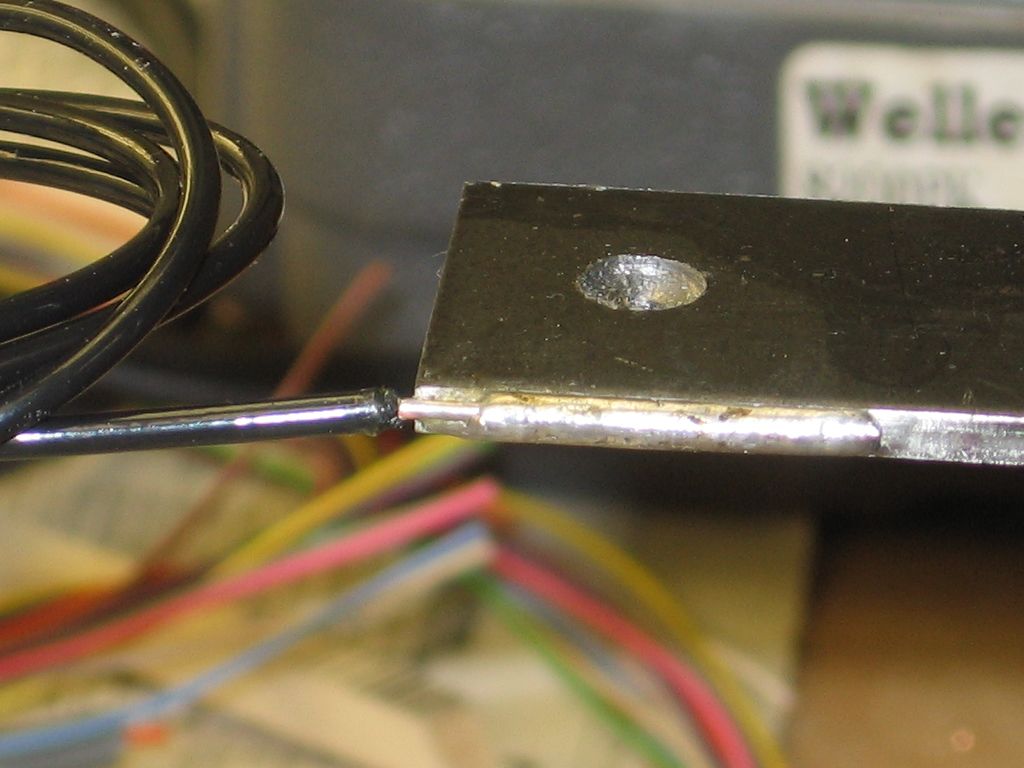

15% of the time, the shiny outer rails on a "problem track section" will not take solder. I tried different fluxes, I tried 60/40 solder and 63/37 solder (no lead-free--all real solder), I tried more aggressively grinding the base of the rail and .... no good. Finally, for these relatively few track sections, I dug out a tiny drill bit, drilled a hole in the base of the rail, wrapped a wire around a #2-32 sheet metal screw and screwed a wire connection to the rail. This yields good continuity but certainly not the reliability of a soldered connection.

Has anyone else seen this and found a solution?

Don Merz

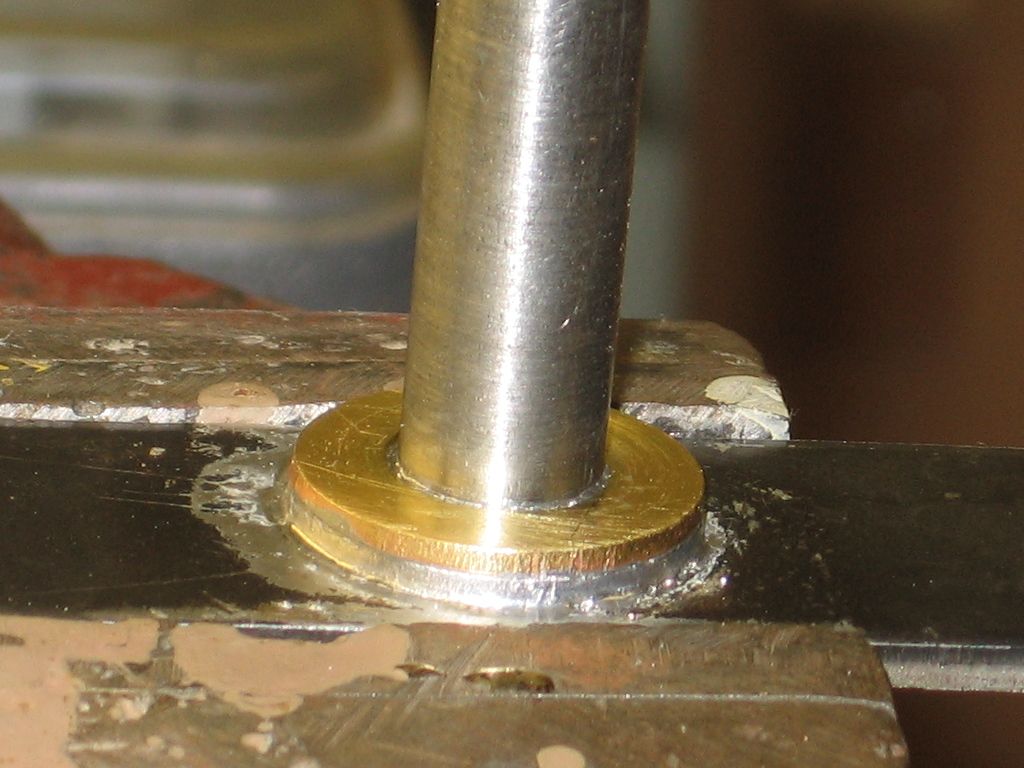

Also these brass washers to the turntable shaft. Map gas /propane torch was used.

Also these brass washers to the turntable shaft. Map gas /propane torch was used.