I'm starting anew topic with this one just to avoid having a lot of sub-threads going.

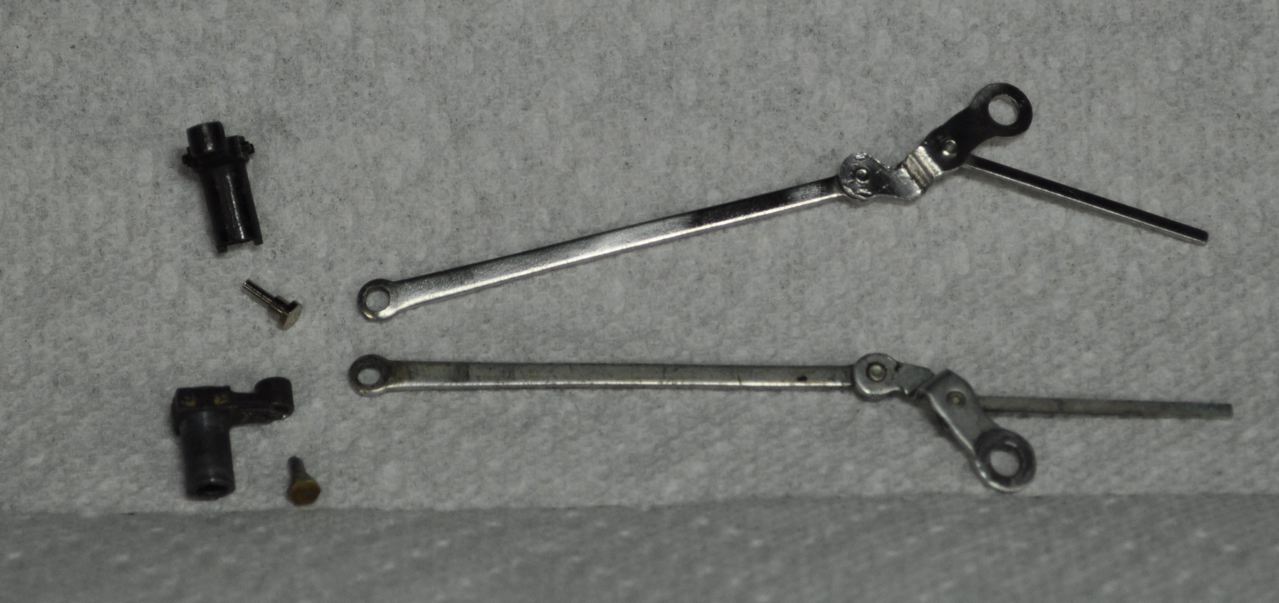

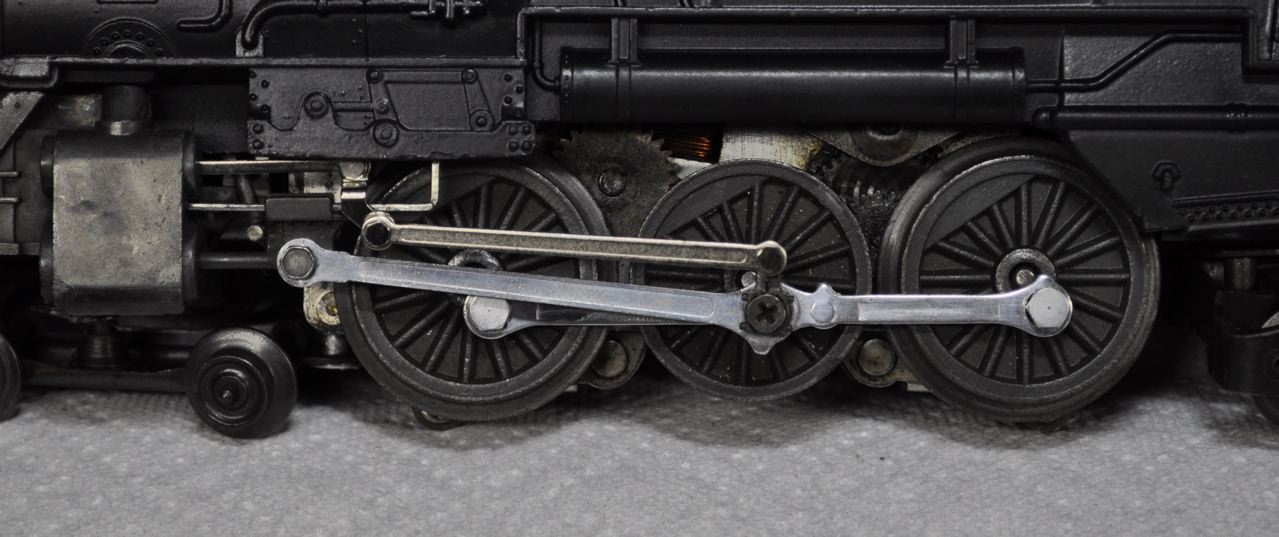

When I'm fixing up an engine for resale, the rods and valve gear are often problematic. I'll have, for example, a 675 that is C6/7 except that the rods have a lot of rsut. Or maybe not rusted but so corroded that they don't match the body.

My first impulse was to wire brush, but then I read that this may hurt the finish. But how bad is that if the original finish is marred by corrosion. What alternative are there ?

I'd like to hear ideas about what's the best thing to do with rods and valve gear. I'm not tryign to sell to the set of collectors who must have perfection, rather those who would rather accept imperfections to get more pieces they want to have at a reasonable prices. I wonder what the proportions are of those two groups.

Of course appearance isn't the only thing. I want to say that anything I sell will work well.

They key question here perhaps isn't so much what's best as it it what's least bad.

Malcolm Laughlin