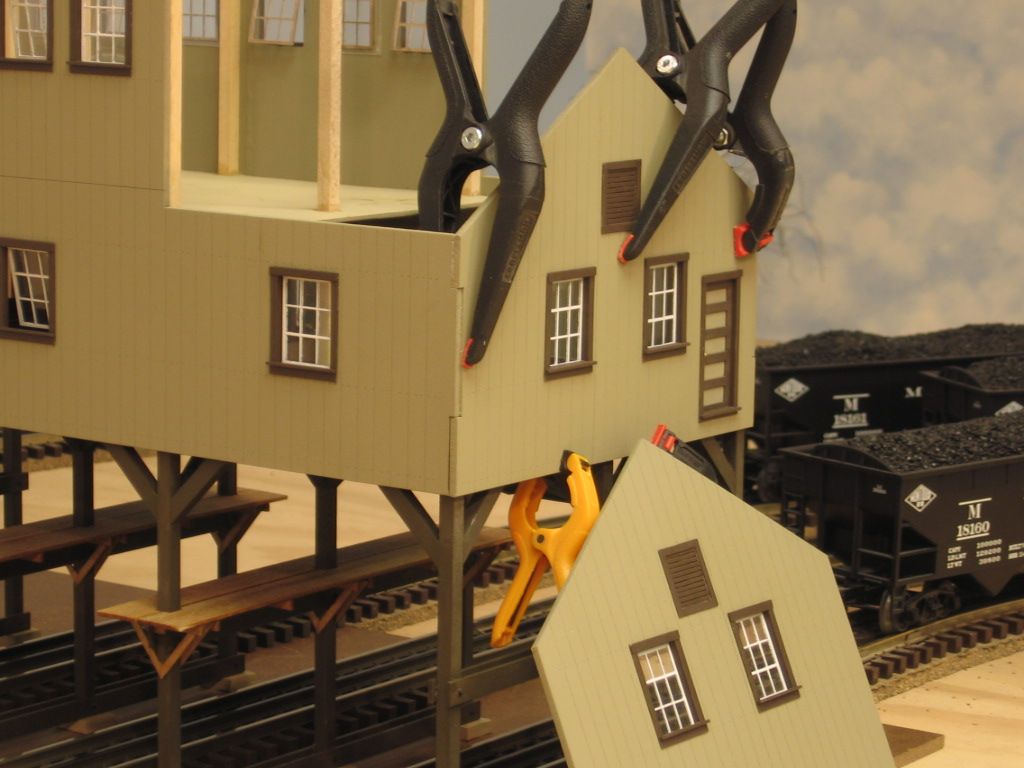

There is lot's of stuff out there, you need to do some shopping. I made a living with tools (electrical contractor). Two items that were purchased, when I decided to do a layout. Small table top band saw, and a disk/belt sander.

Band saw.

Disk/belt sander, most used tool.

IMO you would find that styrene plastic tends to melt when you use heavy duty cutting tools. You would be into a lot of cutting with exacto-knives and sanding. Required: good straight edge and squaring tools and a cutting pad.

Both tools pictured require the: Safety meeting of the day. Becareful, you only get one set, (10) fingers. Eye protection should be worn.

Best wishes with your project. Mike CT.

I review this picture from time to time just to remind me how stupid I can be. But this was done by DJ, a seasoned carpenter, who helped with my layout. A quick look away from the table saw, and this happened. The piece hit DJ in the stomach, no damage other that what is pictured. Second Safety meeting of the day. No tool has any respect for a human being.