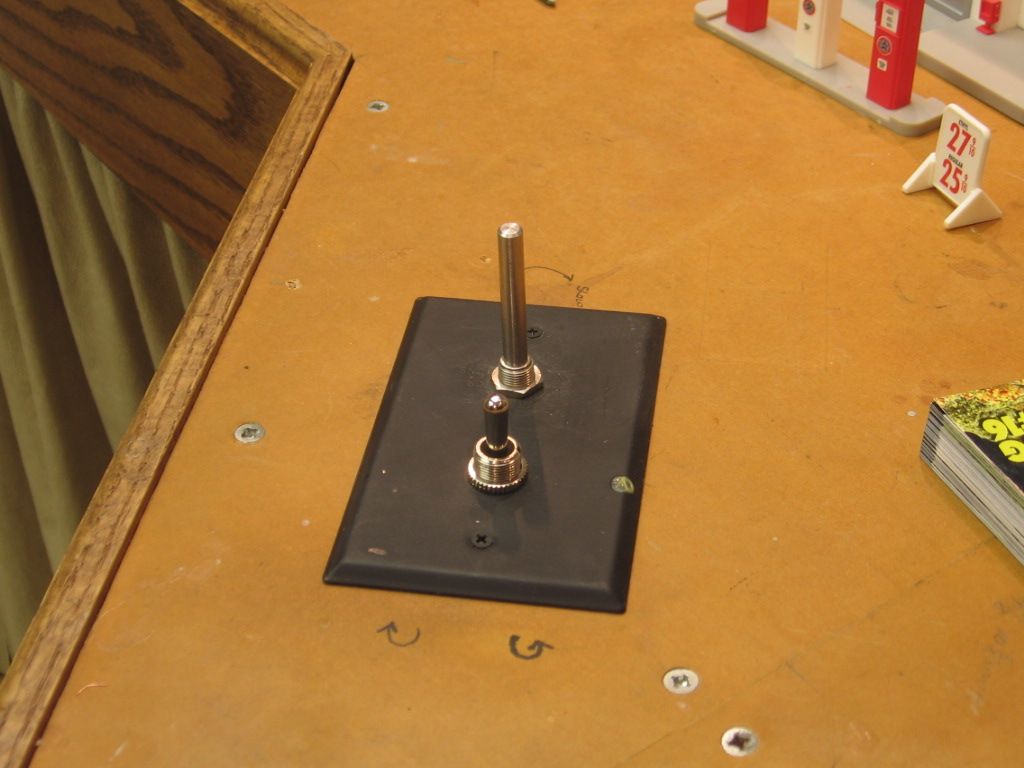

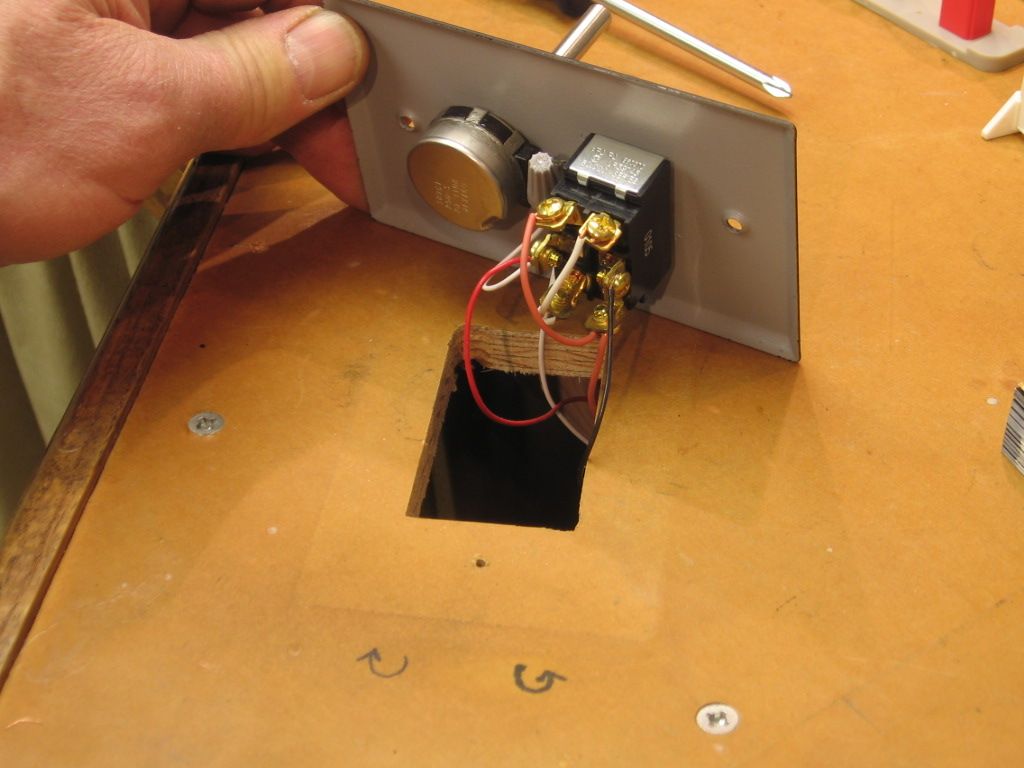

I have started to fool around with my turntable and determined that it must be a Diamond Scale turntable with indexing. I put power to the motor and am not getting any movement but the motor is humming, so I took the gear box apart and did not find any problems with the plastic gearing but discovered the motor shaft not spinning. I need a new motor which it appears that I can get from Diamond. The other part of the story is that I looked carefully at the indexing control board and it appears there is a blackened spot on it so I think I will need to replace that also. My question is, if I determine to do a retrofit to the turntable drive/indexing system what is available that I can use? The turntable is close to the edge of the layout so I’m not sure if I need to have the indexing system (it has that now) or if eyeballing would be better. Here are some photos of the set up: