Lookie what showed up in the mail today!!!!

Just cracked open the box for my Vision Line Greyhound Challenger (6-11211)

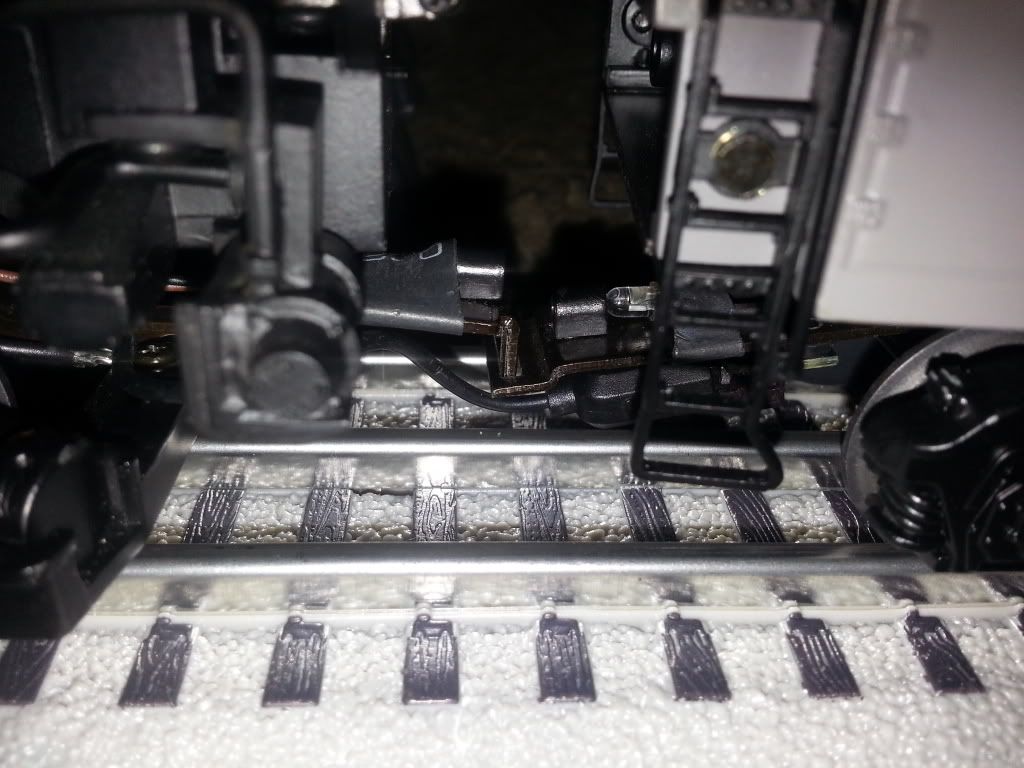

1st issue i'm having is that when i connect everything on my table (or flat section of FastTrack) the tender seems to sit too low for the engine drawbar to connect. I connect the wire that goes under the drawbar. then when i put the drawbar into the receiver on the tender, the tender piece sits too low for the "wireless link" sensors to line up... so i get very poor/minimal sound. No chuffing, no whistle, etc.

2nd I am getting smoke from the main Stack(s) but when i blow the whistle, i am not getting any whistle steam... all the switches are on..