Does anybody know what a worm drive is for a old Lionel steamer?

What are the pros and cons of having this type of drive?

Thanks

|

|

Does anybody know what a worm drive is for a old Lionel steamer?

What are the pros and cons of having this type of drive?

Thanks

Replies sorted oldest to newest

A worm drive looks like a barrel on the motor shaft with a spiral groove running end-to-end. As the barrel rotates, the grooves "move" from end-to-end relative to a fixed spot (where the next gear would be in contact with it)

Advantages? Smoother operation, lower minimum speed (depends on the angle of the groove), etc.

Disadvantages? the drivetrain won't freewheel, it (usually) can only be operated from the motor end.

---PCJ

The worm drive is usually quieter than regular gears. Note that modern locos, with can motors and flywheels, are usually worm drives. They must be kept well lubricated.

The gear ratio is equal to the number of teeth on the spur gear; with a single worm, the motor makes one revolution to push that gear the space of one tooth. Note that the old Lionels used a "double" worm drive, in that there are actually 2 threads on the worm, meaning one rev of the motor moves the spur forward the space of 2 teeth.

Almost ALL Steam Engines use this kind of DRIVE!

Fredstrains

Almost ALL Steam Engines use this kind of DRIVE!

Fredstrains

Fred, several decades ago, most Lionel locos were not worm drives, but had side plate, open frame motors using spur gears. The motor shaft was transverse to the loco. It came in 6-wheel & 4-wheel versions & was apparently cheap to make, since it was on Lionel's cheaper locos.

As an aside, the brush mounts on these were not electrically interchangeable although they were mechanically interchangeable--there were at least two different layouts of the brush holders.

There are many articles about worm drive on the web. Here is one:

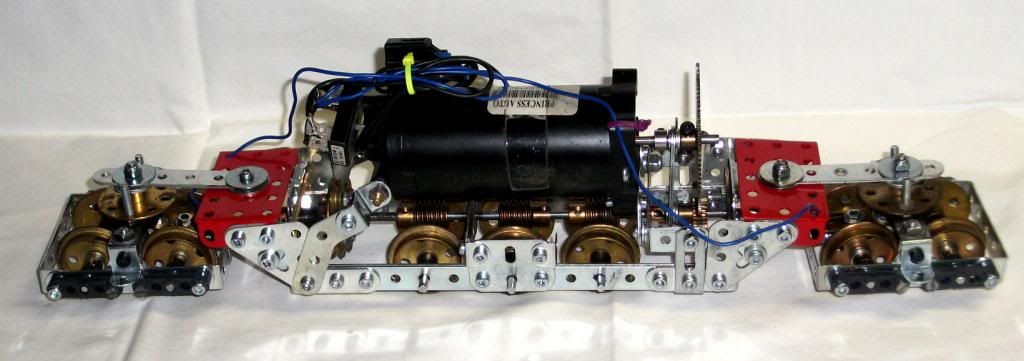

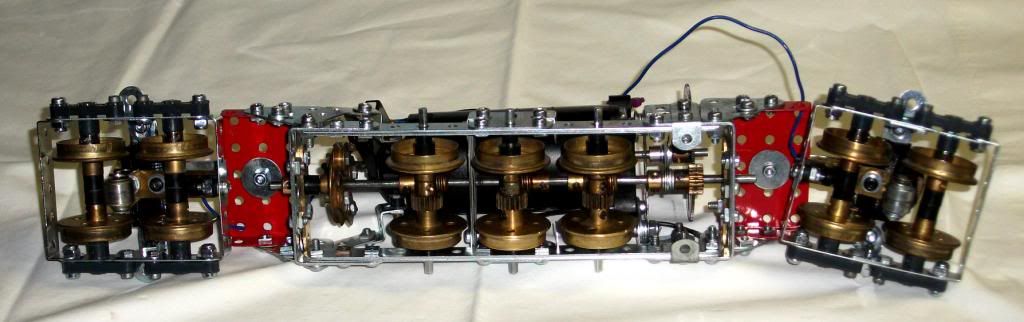

Do it yourself worm drive engine for 3 rail o gauge:

Do it yourself worm drive engine for 3 rail o gauge:

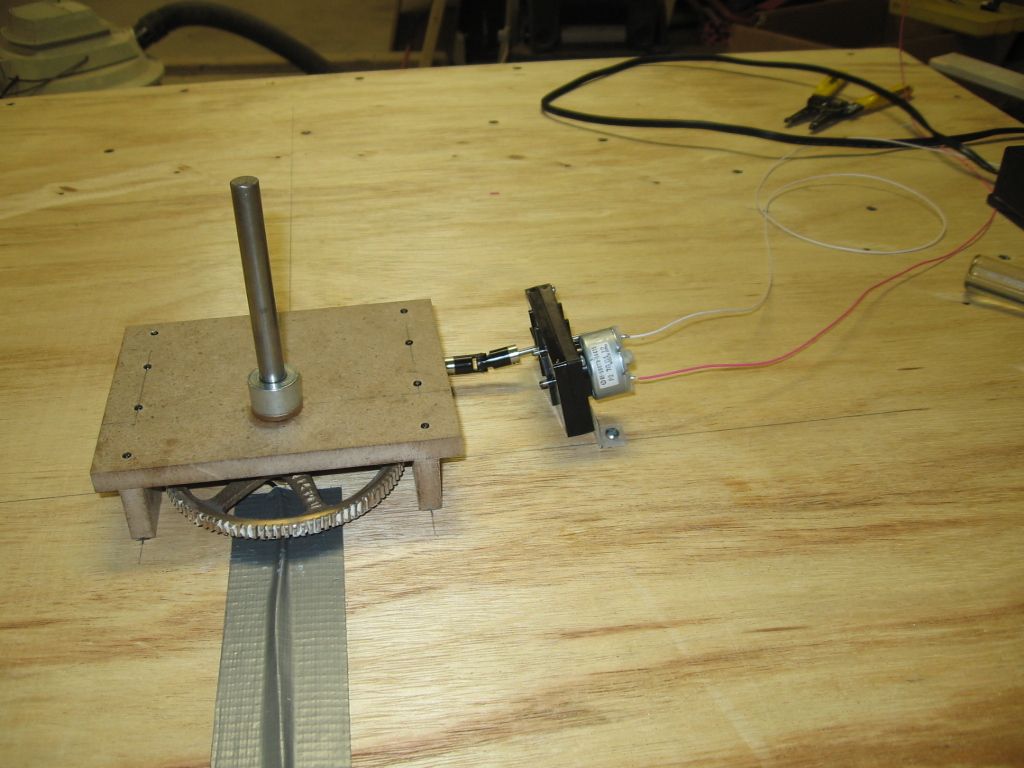

Worm drive assembly for a turntable Allows for a very small motor and a lot of torque. I believe this was 50 to 1. (50) turns of the smaller worm gear to (1) revolution of the geared wheel. You don't want this to catch or bind in anyway, even with a very small motor something will give/break.

More gear reduction in the small black case. A very small 12 volt motor.

Thank you everyone for your informative responses.

Very helpful!

Mike, I like that turntable drive. The Bowser friction wheel is a pain.

Disadvantages? the drivetrain won't freewheel, it (usually) can only be operated from the motor end.

Not necessarily true... the direct worm drive used by Lionel on most Postwar and MPC-era locos was free-wheeling and reversible. On a 736 for example it's easy to turn the wheels by hand and see the motor turn. It has to do with the lead angle of the worm, the number of threads, thrust play, friction of the materials and lubrication.

I always thought the worm drive in the 773 was self locking. But I recently learned on this forum that, once properly adjusted and well broken in, you can turn the wheels of a 773 by hand. Since I read it on here I experienced this in person and I know it's true. I wouldn't force it on a valuable model, but I *know* this is true, I have seen it.

The worm gears in all of the MTH steam and diesel locos I've examined have been self-locking. Same with the Korean-made Lionels of the early-to-mid 2000s. However, with the debut of the Legacy system, I've noticed Lionel has returned to reversible worm gearing on most of its premium steam and "LionDrive" diesels. I think this is GREAT! These locos don't grind to a halt if an inexperienced operator flicks a toggle at the wrong time. My 11203 Berk has two flywheels and reversible worm gearing. It will actually coast about 18-24" from full speed when power is cut. I'm sure the Vision Line Hudson is about the same.

Mike, I like that turntable drive. The Bowser friction wheel is a pain.

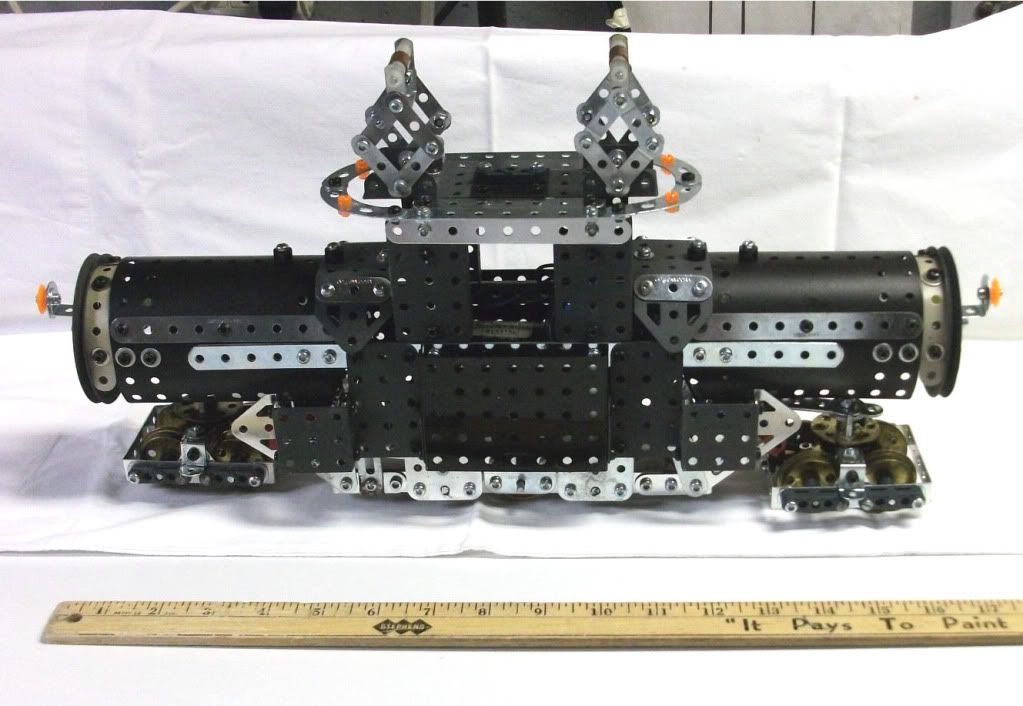

Pictured is a Diamond Scale, (O-scale), Drive system. The Worm and Drive Gear (WG-9) is Boston Gear also requiring (WS-87 shaft). The 7/16" Turn Shaft and Drive Block turn bar were fabricated locally. Thrust washers and shaft collars were purchase from Diamond Scale (listed on the price sheet). .

And I thought that it was a variation of a Beetle Drive. Or am I just showing my age again? ![]()

According to the article I linked above, worm drives are probably going to be self-locking when the gear ratio goes above 30 to 1.

Whether a worm-drive mechanism can free-wheel when driven from the gear side also depends to some extent on turning resistance of the motor which has the worm on its drive shaft. DC permag motors with more "cogging" will have more resistance to free-wheeling. I remember there was an article on worm-drive mechanisms and their ability to coast in Model Railroader magazine, many years ago.

One of the wonders of the forum is that a simple question can provoke an extensive discussion.

NQDY: The beetle drive is somewhat different: there were six fingers that pushed on a level device.

CWB: I wonder of the controlling factor isn't the pitch angle on the worm rather than the number of teeth on the spur gear?????? The old Lionels had a very large angle, due in part to Lionel's use of a double worm thread.

Access to this requires an OGR Forum Supporting Membership