Finally got around to converting the old AC incandescent lights in my Buco 4 axle passenger carriages over to LEDs.

With the help of gunrunnerjohn supplying me with his tiny AC to DC voltage regulators, and picking up the rolls of LED strip lights on AliExpress, I was ready to give it a crack!

The original Buco lighting system was one 18V bulb per carriage, suspended from the top of the carriage via a stiff piece of cardboard. The wiring is "daisy-chained" between each carriage, and power is supplied from an outlet at the rear of the larger 304 and 314 Buco loco's. There are no pick-up rollers on these Buco carriages.

Above is the "restaurant" car (they were painted red as per the protype) showing the "daisy-chain" wiring system to power each cars light, and the single light globe suspended on cardboard providing illumination???

Above is a photo (very poorly taken, I admit) of the incandescent light emitted by the single light globe.

So installing the new LED's, I needed to maintain the "daisy-chain" wiring to get track power all the way down the consist to the last carriage, so the small (Buco HO) plugs were retained at the ends of each carriage.

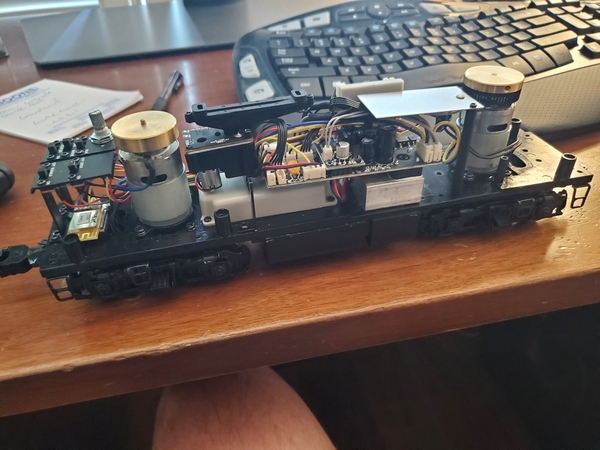

I took a "tap" off the positive (+) and negative (-) leads inside each carriage to power a lighting board (supplied by gunrunnerjohn), and then leads from the board to power the LED strip, which was cut to suit the length of the carriage. See photo below.

I glued the strip of LED's to a timber skewer that fits perfectly at each end, in grooves in the tinplate where the original "daisy chain" wires were located.

I finally completed the conversion to all six (6) of my Buco passenger carriages yesterday, and the difference is night and day (pardon the pun)!!! See photo below.

I use one of my Williams GG1 loco's to pull this train, as it has got some "grunt", so I needed a transition car with a knuckle coupler to hook-up to the GG1, and a drop-link coupler at the other end to couple to the Buco carriages, hence the MTH "Milwaukee RPO" carriage that also has the roller pick-up to provide track power for the lighting system.

Just love the conversion, with no "flickering" of the carriage lights as the train transverses the switches, and the illumination inside the carriages can now be seen!!! I didn't have to worry about seats or passengers visible through the windows inside the carriages, as this was well beyond this Swiss manufacture, back in the early 1950's.

Full credit must go to gunrunnerjohn for helping me with this conversion, for supplying the circuit boards, and pointing me in the right direction about which rolls of LED's to get. Thank you John!!

Peter.....Buco Australia.