Originally Posted by sinclair:

Originally Posted by Marty R:

I guess my remaining fear is torque on the lead coupler

Being that torque is a rotational force, the coupler doesn't experience any as it is not spinning. Therefore you don't need to worry about it. Sorry, I'm a mechanical engineer and it bothers me when people use the wrong terminology. Shear and tension would be the concerns at hand, shear on the bolt holding the coupler and tension on the coupler finger. Neither of which would ruin the locomotives. Worse case is you can't get the broken screw out of the front of the locomotive which means you'd never be able to put it behind another locomotive. And the only way you could ever get anywhere near the levels of force to inflict that kind of damage is if you are running them at full speed and then the rear locomotive stopped dead. And as I've never seen that (If a locomotive gears lock up at that speed, it'll still skid a bit, even with traction tires. Been there, done that.), I think you are good to go double heading.

But I do feel your pain on damage. 3 Christmases ago my cats decided the tree looping train would be a good place to have a tussle. Woke up in the morning to a locomotive on it's side and the rear coupler finger broken clean off. The little 0-6-0 finished it's Christmas service pulling the train backwards that year.

AHA Mr Engineer! I believe I was referring to the torque placed, on the coupler, when a dog, or clumsy human caused an abrupt derailment, ie: tipping the loco. Which, I think, would put rotational stress on the coupler.

"I guess my remaining fear is torque on the lead coupler. It's a Christmas floor layout. The dog, and occasionally the errant Human, has been know to assist in rather abrupt derailments."

My daughter is an Engineering major at MIT, she would assure me, it isn't a character flaw to insist on the precise use of language, while ignoring the possibility of implied meaning in the rest of the communication.

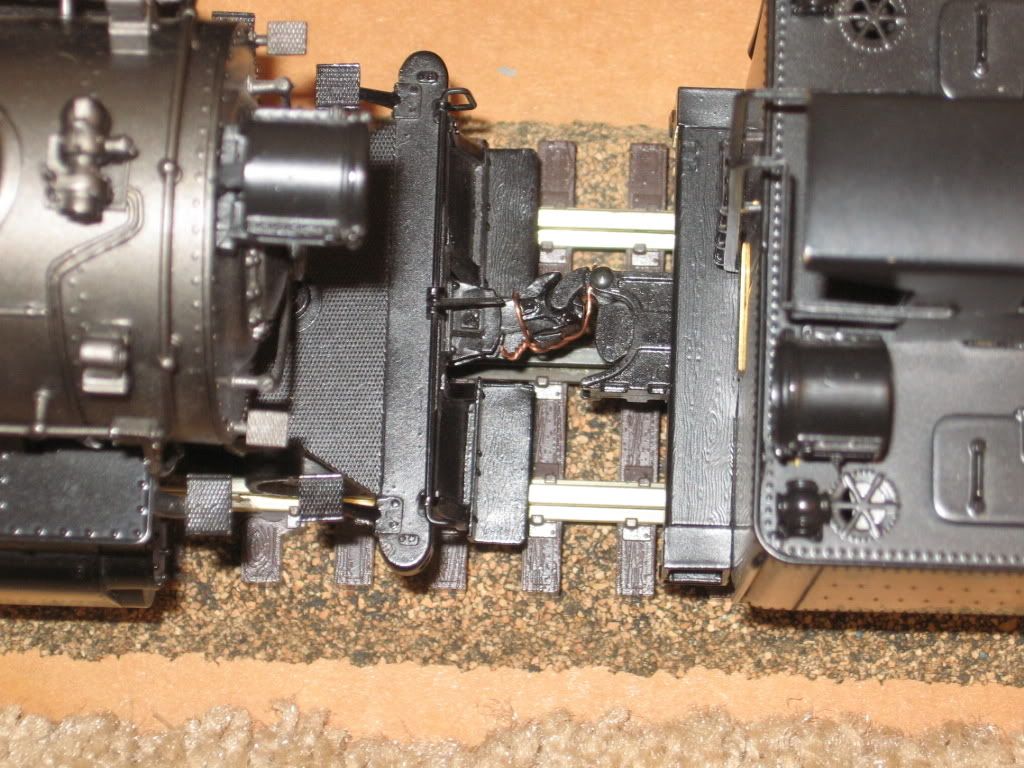

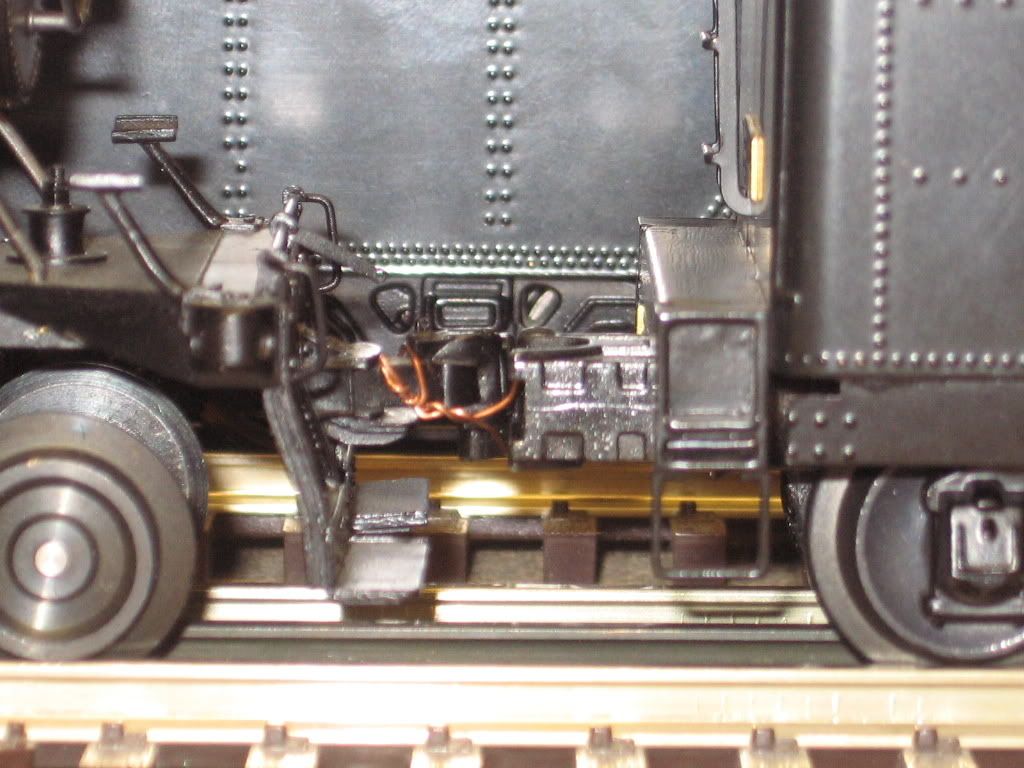

In my mind, the worst case scenario was snapping bits off the front end of a premier steamer. Any damage there and I'd have to hope MTH still produced the proper bits and had them as repair parts, rather than manufacturing stock. This dummy coupler seems to have very little rotational play to allow it to slip from the other coupler. I'd be relying mostly on the forgiveness of the tender coupler on the lead loco. Having stopped typing and gone to stare at the coupler mount, it has a little more oomph (sorry, I don't know the engineering term

, so the problem probably isn't a problem.

, so the problem probably isn't a problem.

So you see, it wasn't that I misused a term, it was that I didn't understand the system.

As to the cats, yep. My trains are at risk if I get lazy and park them under the window. We leave a clean path through the layout, to the window and she uses it. It's my fault if I leave a loco under her window, but I did it this year and of course, it was the berk, right where she lands. Only damage was a lost handrail. Snapped it at the insertion points.

![]() I was surprised when I noticed it. I hadn't stared at the coupler box long enough to believe it was strong enough ad have had enough carpet level, train got bumped by dog or human derailments, to be leery, of the process.

I was surprised when I noticed it. I hadn't stared at the coupler box long enough to believe it was strong enough ad have had enough carpet level, train got bumped by dog or human derailments, to be leery, of the process.