As a 2-railer, I realize that handbuilt brass is much more fragile than diecast mass produced locos. I currently have sunset 3rd rail steamers and 2 of the older ones when it was just called Sunset. In 2 rail, we install our own control systems, at least in older ones, so electronic wizz-bangs are not an issue. I also have the recent Gas-Electric. They need to be handled as a scale model.

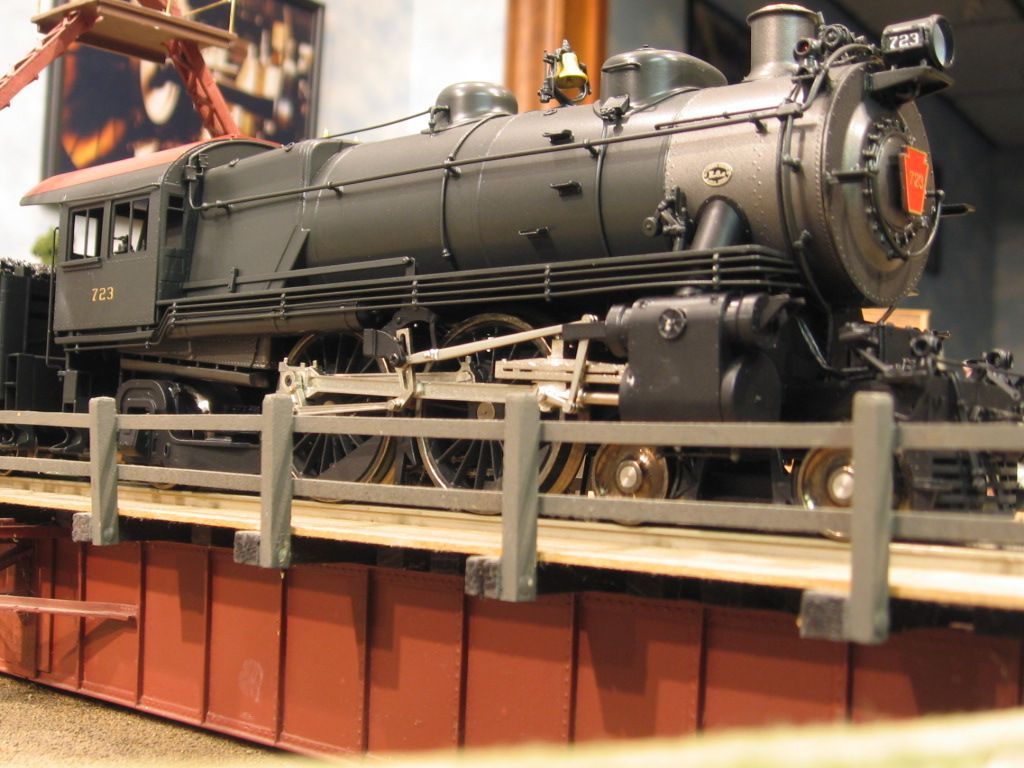

As stated the detail is much better generally than diecast. This is especially obvious in the thickness of things like tender coal boards, or cab sides.

Another big, big point is that all the steamers have articulated side rods (the rods connecting the drivers to each other). this allows them to navigate sharper curves. All the diecast I have seen (admittedly somewhat limited) have one piece side rods. One piece works fine in 3 rail if all except center drivers are blind. However, if the center drivers have flanges as most 2 rail, one piece side rods limit side play on curves quite a bit. For example, I have a Max Grey PRR 2-10-4. It will go around 54 inch radius curves. I test ran an MTH version of the same model with solid side rods and it would just barely navigate 72 inch radius!

Mechanically, most of the 3rd rail stuff has been really good. All of mine have great mechanisms and run well and smoothly. I particularly like their belt drives. I did have some problems with their High Iron K4 when I test ran it. But it was mostly due to a very new and tight mechansim I think.