|

|

Replies sorted oldest to newest

quote:Originally posted by jmik26:

. I didn't know that and now I am stuck doing the repair on my own.

quote:Originally posted by jmik26:

I am trying to stay positive but I am slowly getting to the frustration point.

quote:

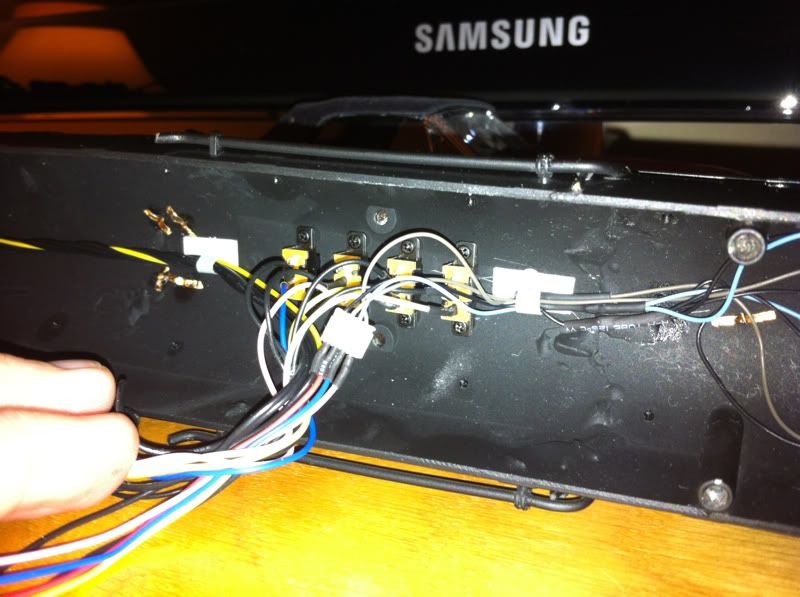

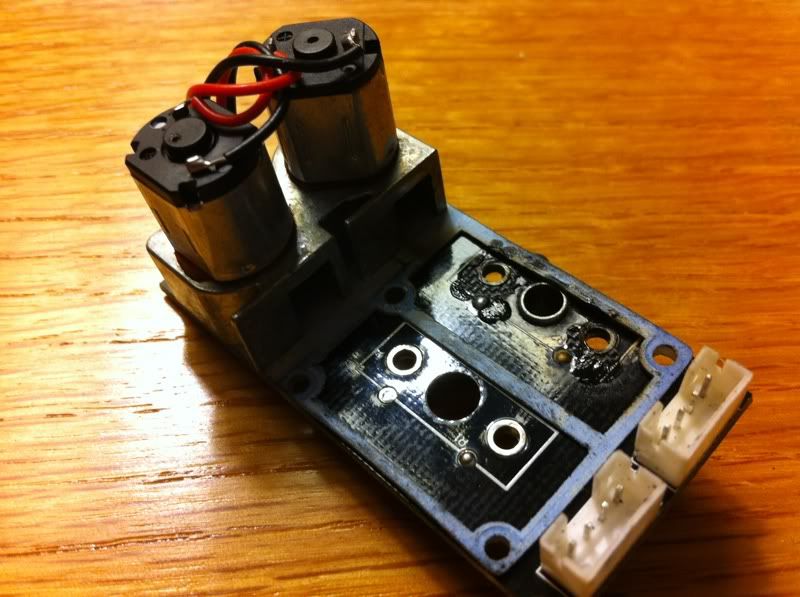

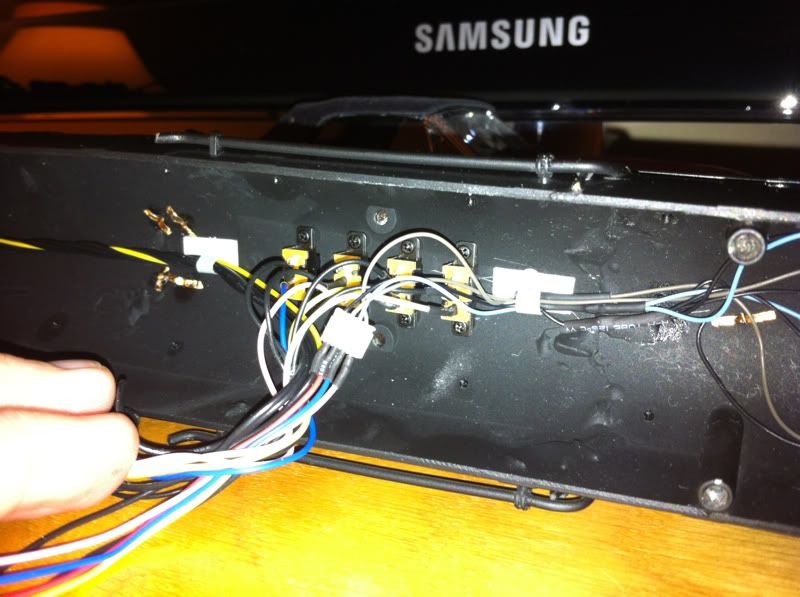

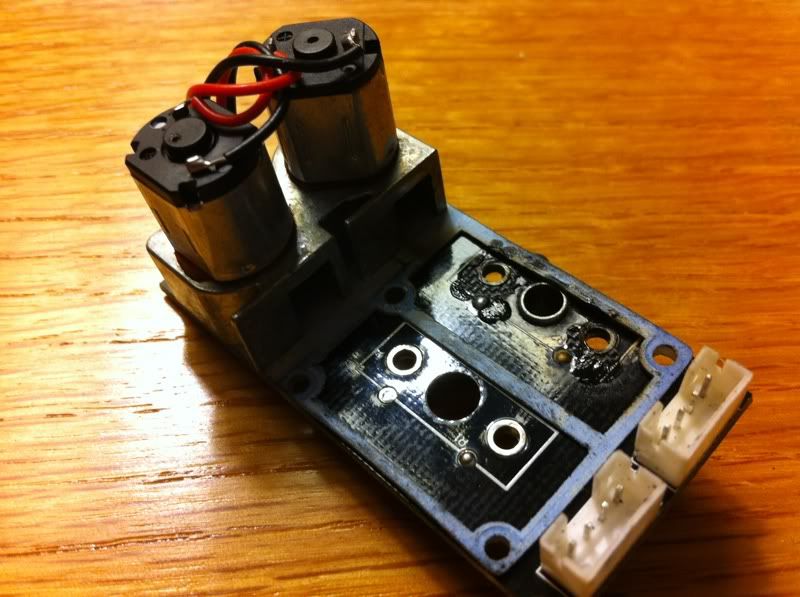

1. I also voided my warranty by opening the boiler shell. The main stack smoke output was poor and I thought that it was a standard maintenance job to service it by, for example, checking the resistor\wadding contact and priming the unit directly rather than through the stacks.

quote:Originally posted by jmik26:quote:

1. I also voided my warranty by opening the boiler shell. The main stack smoke output was poor and I thought that it was a standard maintenance job to service it by, for example, checking the resistor\wadding contact and priming the unit directly rather than through the stacks.

Yeah, I kind of thought the same thing, like brakes on a car. I guess my own faults just help pour salt on a wound, lol. I sometimes think if it worked fine I wouldn't have to be doing any of this but I guess all that gets thrown out the window once you take it apart.

I did get a response back from Mike giving me the idea of spraying compressed air into the steam chest. I am gonna give it a try.

If that don't work I am gonna give serious thought to putting it up on Ebay at a discount. I am sure I can buy another one once all the problems have been worked out...

quote:I guess my issue is, is it guaranteed to work perfect after the repair?

quote:Originally posted by breezinup:

Personally, I'd put the engine back together without "repairing" the resistors or anything, and send it to Lionel for repair......Think about this: What if you proceed to do the "repairs" yourself and put it all back together and it still doesn't work right? Now what? Open it all up again and start experimenting?

quote:Originally posted by Hot Water:quote:I guess my issue is, is it guaranteed to work perfect after the repair?

It was "guaranteed to work perfect" when you purchased it originally, what the devil is the problem with Lionel repairing it? For crying out loud, please stop whining about it and send it in! Mike will fix it "perfect"!

Access to this requires an OGR Forum Supporting Membership