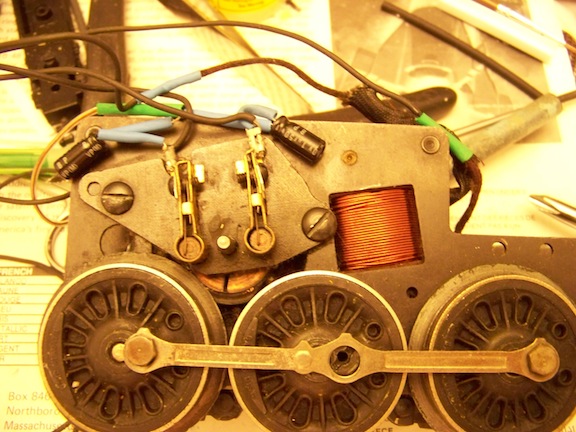

I'm getting ready to install the ERR AC Commander in a pair of traditional spur-geared steam locos. I'm intending to place the antenna and circuit board in the tender shell, and run a multi-wire tether back to the loco for motor power.

The instructions call for snubber capacitors to be connected across the motor brushes. The illustrations suggest a Berkshire type motor or diesel. Has anyone here installed one of these in a Postwar 2046, 2037, 675, 1615, etc.? If you have I would LOVE to see some pics of the assembly, especially your brush plate side with the capacitors. Were you satisfied with the operation? Any advice is most welcome! Thanks!!