OK a little late on a 'timely' post on this subject, but I'm buildin and just finalized my panel design.

So JIC anybody goes searching, I'd like to show what I came up with. I think it fits my bill pretty well, and has the 'feel' of prototype + O-gauge + simplicity ...

I had a couple considerations to factor in.

1. I wanted 2 cab control

2. It needs to be informative, and easy to understand

3. Simple enough for a 3 yr old (grandsons) to operate

4. Big enough for those with 'all thumbs' and/or 'aging eyes' to easily operate

So here's the panel (less most hardware)

Panel is 24"w x 12"h. Switch controls have a silver 'box' to help group things clearly (but cleanly)

Crossover Switch control and indications. There will be 2 green leds and a yellow when the switch is on crossover position.

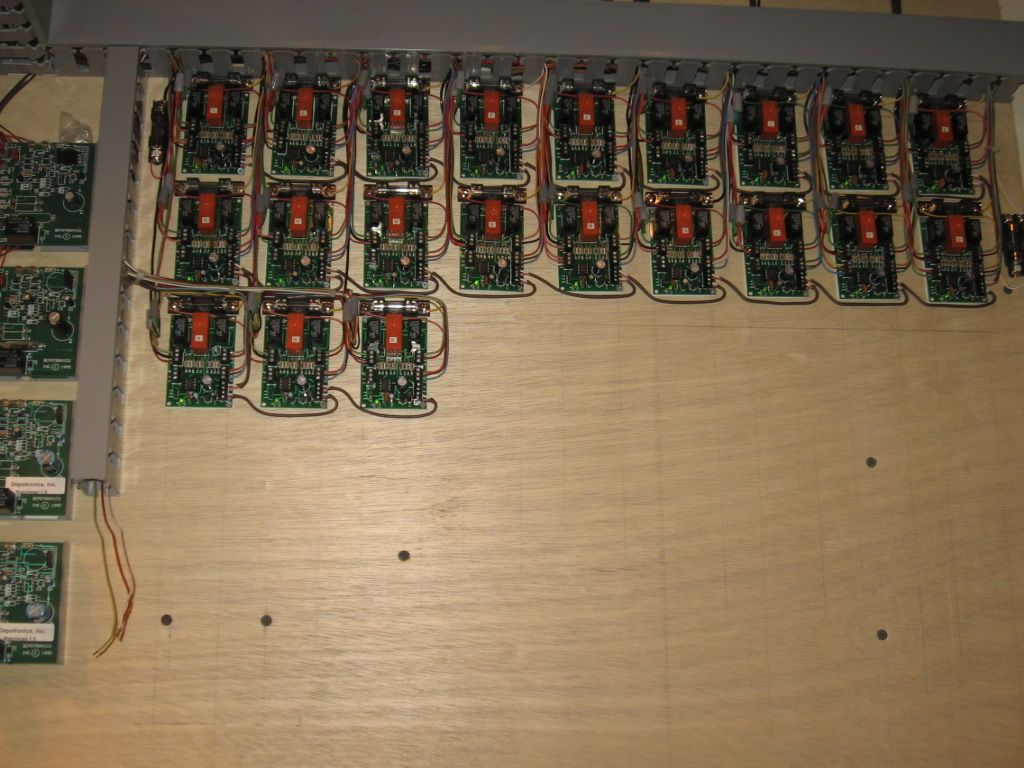

The Standard switches are simple red/green buttons and leds. Because of the way the lionel fastrack switches work, there can be multiple panles/indicators for each switch, and when Legacy/TMCC comes in to play the panel(s) will by default follow all switch activity.

Block control will be with a standard heavy duty SPDT-center off Toggle switches (block breaks currently not shown, I need to add to the art.

Switches installed

I guess Im kinda doing a progress post at this point

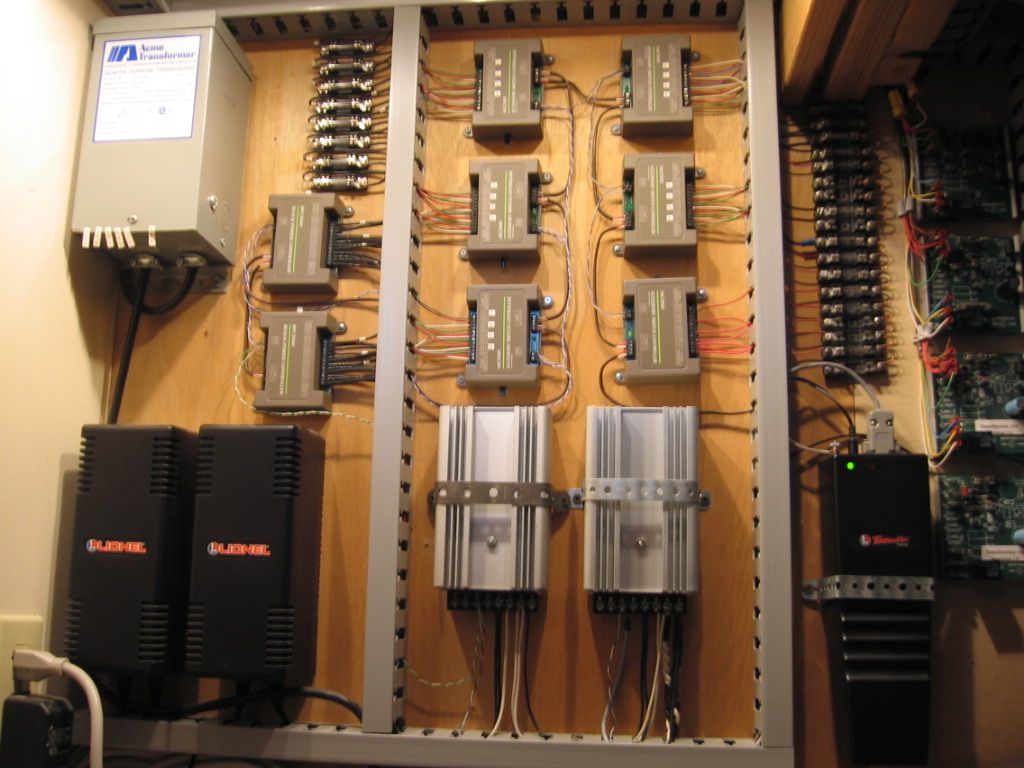

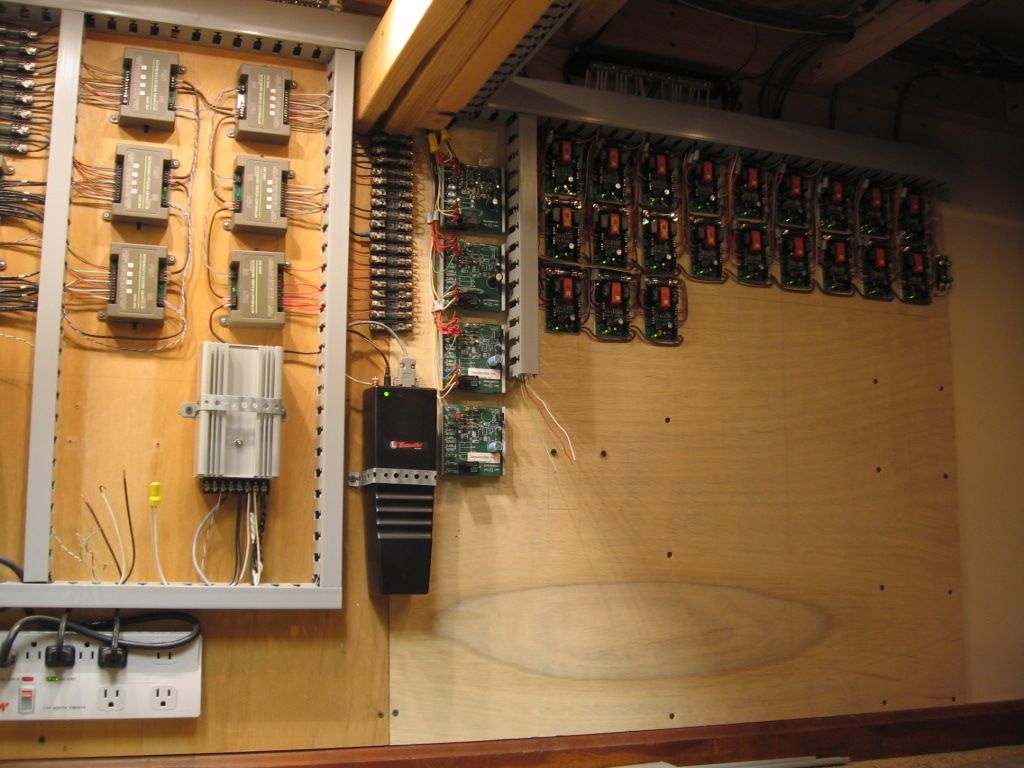

Just a bit of wiring, I used 22/4 stranded wire (alarm cable / stranded telephone wire) and labeled the heck out of everything

I also made it about 6 feet longer than I needed, so I had plenty of 'service loop' and I can relocate it just about anywhere around the island it is on ....

Not a great shot, but up and running (still have a few sidings to contend with tho)

I decided to add some mini toggles later for uncoupler control ....