Ok im Finally getting the ambition and courage to on upgrading to TAS EOB...any help and advice is appreciated.....Can I mount the boards sideways?..cant bolt them top side..because of my tender clearance...going to mount my speaker at the front of the tender to make the sound more closer to the engine...like the one guy did to his steamer..love the idea..never like the speaker at the rear of the tender...

Replies sorted oldest to newest

You could probably mount them sideways but you will have provide a heat sink for the power devices on the bottom of the board. It was designed to be mounted so those devices are mounted to the floor. They have a tendency to overheat and fail so I wouldn't compromise their cooling just to move the speaker.

Pete

It's a tedious process. I cut all the pins so that the three Lionel boards fit as close to the mother board as possible. Most of the factory equipped EOB that I have has been altered that way. You should gain about 3/8"

I couldnt mount the board under the coal side of the tender...because of the board lenght...if it was a inc shorter I would...as for cutting the pins..dont like to cut them,mainly because the resitors close to each other as is..I think I got some aluminum angle I could cut to lenght and bolt it to the floor and to that aluminum bracket on the bottom of that board..that way the heat can still transfer to the tender floor...Question..if those boards get that hot,,why didnt they installed mini fan in the tender to keep them cool...

I don't think the output devices get any hotter than say a Lionel board but the funky mounting system can cause the devices to lose contact with the heat sink.The two EOB boards I had to replace had blown outputs. However you end up mounting them make sure you use heat sink grease and tighten then down.

Pete

You need to connect that big elephant ear heatsink to something metal. As for cutting down the posts, it won't hurt anything. Keep in mind that with those tall posts, when you cut them, they have sharp edges and are almost impossible to align to get the boards on! I had to carefully file the posts to a point again when I cut one of these down to make it fit, lesson learned! I used foam backed tape to insulate between boards after I cut one down.

A fan doesn't do anything for you unless you also have fresh vented cool air to circulate.

I don't think heat will blow the boards as a rule, but I know if you short the motor leads to the frame, they will go rather quickly! Replacing the triacs is a PITA, but it can be done, I've had to do it twice on these boards.

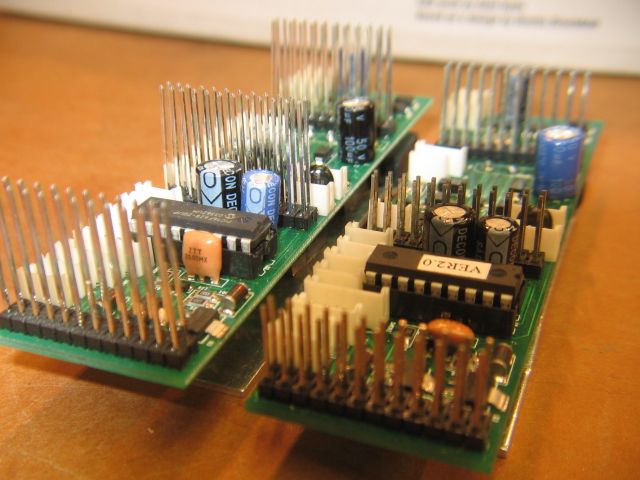

Not necessarily for the faint of heart. ![]() Pins cut on the right board.

Pins cut on the right board.

I did that, as I pointed out, the cutting leaves sharp edges and makes it much harder to get the pins all aligned. After a few passes with a file on all sides, it was much easier to install the boards again.

IMO. Hand cut only and use a hand file as John mentioned. I custom cut an older Digital Dynamics board and used a belt sander to clean the ragged ends. The word "dumb" applies. ![]() Mike

Mike

Can we say "static electricity"! ![]()

john,what do I use to cut those prongs>>mini side wire cutters? also in the pics is this the foam your talking about?..That big heat sink isnt attched to that bracket but the nut would be agaist that and the floor...but there 4 smaller heatsink thatsbolted to that alum bracket..where do I place that foam at..??I did pick up a alum plate if I deside to mount the boards sideways..think I can place a mini fan too..can use the old speaker holes to push the hot air out..and maybe cut a slot hole some where in the coal load to let in the cool air..hey its a idea.

I used side cutters, but then as I said, you have to carefully taper the pins the way they come originally so that the boards will plug into them easily.

I really don't think you need a fan, just use a 90 degree bracket from the big heatsink to the chassis, perhaps one on each end of the heatsink to the chassis.

john,what do I use to cut those prongs>>mini side wire cutters? also in the pics is this the foam your talking about?..That big heat sink isnt attched to that bracket but the nut would be agaist that and the floor...but there 4 smaller heatsink thatsbolted to that alum bracket..where do I place that foam at..??I did pick up a alum plate if I deside to mount the boards sideways..think I can place a mini fan too..can use the old speaker holes to push the hot air out..and maybe cut a slot hole some where in the coal load to let in the cool air..hey its a idea.

You can use a 4" side cutter. I would cut some kind of metal or plastic sheet stock placed between the rows to use as a guide. You should be able to guesstimate height using Mikes pics as a guide. After cutting you could use that guide to support the pins as you file them to a point.

Pete

I did cut the pins lastnight..you wont believe what id used on it...used a toe nail clipers on it..and i didnt need to file them down neighter..boards pluged wright in with no problem.....now got better clearance...Ill mount it tords the coal load area..On the power board id had to bend it back alittle bit..shouldve cut the pins higher up..that big compasender hit the boad....Id put black electrical tap on the bottom of it...Jon could I re use that stock alum mounting bracket that on it now to bolt on the tender floor??

If you look at some of the Lionel boards, they have a plastic guide near the top of the tall pins which keeps them aligned. you could salvage the same piece from a dual-row header and slide it on to keep them aligned now and in the future. I'd put it on BEFORE you do the cutting.

I see you already cut them, didn't see that when I was typing.

You talk about re-using the heatsink, did you take it off the board?

If you look at some of the Lionel boards, they have a plastic guide near the top of the tall pins which keeps them aligned. you could salvage the same piece from a dual-row header and slide it on to keep them aligned now and in the future. I'd put it on BEFORE you do the cutting.

there all cut level all the way accross...but the power supply pins id shouldve cut them higher..because of the big compassender..So id bent the the pins back while the board plugged in back words alittle bit for clearanced..

Yep, gotta' check for clearance before giving them a haircut. ![]()

I see you already cut them, didn't see that when I was typing.

You talk about re-using the heatsink, did you take it off the board?

the alum mount..No I never unbolted it...the mount is stock and bolted from TAS..Im going to re used that mount..

Can we say "static electricity"! ![]()

Actually I bet the sander grabbed the pins and bent them. G

John where should I mount this at?..

Anywhere that's accessible. You can also remove the components and mount the switches and pot individually.

John where should I mount this at?..

Anywhere that's accessible. You can also remove the components and mount the switches and pot individually.

would like to put it were the coal load is at ...but wouldnt it might inner fear with the tender shell?..You said the tender shell will be my attenna..just hate the idea on putting them on under the tender floor..if I have to do it..then I will..just wanted easly access to them..I did grind the tender floor sides down so it wouldnt hit the tender side walls..

I typically put them on the tender floor. You can put them toward the center of the tender at the edge and have easy access to them by just reaching under. You just have to remember where the PGM/RUN switch is vs. the other functions. ![]()

Run/Program switch installed in a Rich Yoder GE44 tonner. Patience, the right size hole and a small triangle file to make the rectangular slot for the switch. Takes some time, you might want to do this early in the project. Two small wires to the left in front of the switch are the electro-coupler wires.

I strip the tender and do all the hole drilling and filing before I mount anything. For locomotives, I tape some rags over everything to keep the filings out of moving bits and then go at it.

Josey, When TAS did these, they used the tender shell as the antenna. You had nylon screws and washers so when you mounted the tender shell it was isolated from the chassis frame. They had the screws listed on the parts list. It is also how the Brass conversions I have done were set up. G

I have a 3rd Rail brass locomotive in for repair now with a TAS EOB setup. They isolated the whole tender, the trucks, coupler and drawbar post are all insulated. Interesting way to do the antenna. ![]()

I have a 3rd Rail brass locomotive in for repair now with a TAS EOB setup. They isolated the whole tender, the trucks, coupler and drawbar post are all insulated. Interesting way to do the antenna. ![]()

so what would be the better way to do the antenna?..thought just isolate the shell from the floor?

The normal way is to isolate the shell from the floor, this was the first time I saw the whole tender isolated.

I have a 3rd Rail brass locomotive in for repair now with a TAS EOB setup. They isolated the whole tender, the trucks, coupler and drawbar post are all insulated. Interesting way to do the antenna. ![]()

so what would be the better way to do the antenna?..thought just isolate the shell from the floor?

Tas also recommended the electrical tape at the edge. It was simple and worked. The alternative is to send another wire forward to the engine and use and internal wire or the hand rails.

I am going to upgrade a Brass Williams J for myself with a TAS unit. I am running a MTH 10 pin harness to the engine so I can control headlight, smoke unit, and possibly a second speaker in the engine body tube. G

I have a 3rd Rail brass locomotive in for repair now with a TAS EOB setup. They isolated the whole tender, the trucks, coupler and drawbar post are all insulated. Interesting way to do the antenna. ![]()

so what would be the better way to do the antenna?..thought just isolate the shell from the floor?

Tas also recommended the electrical tape at the edge. It was simple and worked. The alternative is to send another wire forward to the engine and use and internal wire or the hand rails.

I am going to upgrade a Brass Williams J for myself with a TAS unit. I am running a MTH 10 pin harness to the engine so I can control headlight, smoke unit, and possibly a second speaker in the engine body tube. G

thats what I was thinking..on the tape and a speaker on the inside of the boiler tube...but thats why Id moved the speaker in the tender tords the engine cab..makes the sound comming form the engine..GGG Im going to email you..need to buy some parts from you...mine is a pin harness...

Could someone tell me what TAS and EOB stands for? Want to add it to a forum list of acronyms. And a also short definition of what they are?

Thanks

Could someone tell me what TAS (Train America Studios, Youngstown, Ohio, no longer doing business) and EOB (Engineer On Board, I very good replacement electronic drive system that had a tach drive speed control system provided by Train America Studios. Available in many Sunset, Atlas and Weaver models. The EOB system used three Lionel drive and sound plug-in boards. stands for? Want to add it to a forum list of acronyms. And a also short definition of what they are?

Thanks

Thanks Mike CT! Added to the list.