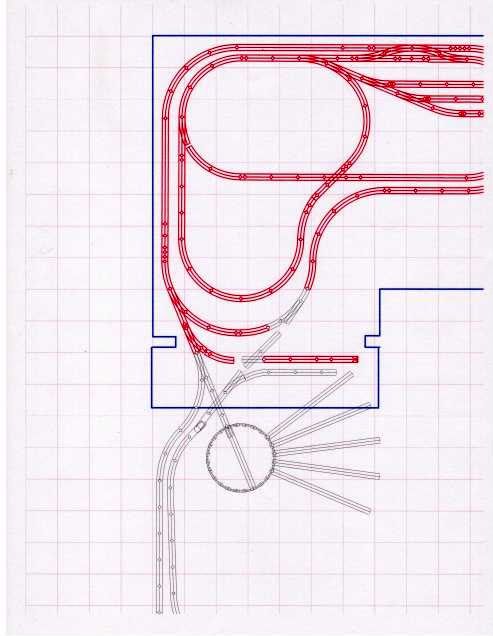

The track plan I created using Atlas O nickel silver track will require cutting a number of straight and curved pieces of sectional track. I have read that a number of people use a dremel to cut Atlas track. Would it be advisable to try and find a metal cutting blade for my 12" miter saw? I'd like to keep the cuts as straight as possible. Another consideration would be a small Proxxon Mini Chop Saw but I'd rather not spend $240 without the cutting wheel(s) if I don't need to. What do you think?

Replies sorted oldest to newest

A Dremel / Roto Zip with a flex shaft and or 90 degree head is all you need for a nice square cut off. Plus you will use that tool (and attachments) down the road in this hobby.

That 12" overkill chop saw could give you a ten ticket thrill ride trying to cut sectional track. It is always safest to size the tool to the job.

I would also recommend a Dremel with a fiberglass reinforced cutoff wheel, it's quick and simple and will leave you with a clean cut. And as Tom stated the Dremel has many abilities.

How about the Dremel EZ Lock Metal Cut Off Wheels? Suitable?

I cut Atlas track hundreds of times with a hacksaw. Secure it in a bench vise and cut to your hearts desire. It works flawlessly, no special tools or jigs needed. You can make cuts even late into the night after your wife and kids are fast asleep !

I have used both the dremel (most of the time) and on occasion I used a metal cutting blade in the compound miter saw (I was cutting the aluminum train shelves at the same time)

How about the Dremel EZ Lock Metal Cut Off Wheels? Suitable?

I find the Dremel EZ Lock metal cutoff wheels to work great. I prefer the thinner wheels as they are quicker and make a thinner cut. I also cut each rail twice. Once about 1/4 to 1/2 inch from the line I want and then the final cut so I can get a good 90 degree cut. I have done dozens of cut this way with great success.

Good luck and happy railroading,

don

I have used both, a Dremel and a 32 tooth per inch hacksaw to cut Atlas track. I true the ends with a final touch-up on a small bench disk sander. I'm relatively conservative and made every attempt to use all the pieces of track I purchased. You may want to consider the Atlas track end pieces (6057) that fit on the track once cut.

From the Atlas website.

Note where the sectional piece don't meet, requires custom cuts.

This is the section that required custom cuts.

Dremel for me, works great! Terry

I use a hacksaw, a C clamp and a piece of scrap wood. Quick and easy, it cuts like butter in one cut and never had any issues with it not being straight. Wouldn't you sort of have to make three separate cuts with a dremel?

I had to cut around 140 sections of Atlas track for my layout, and all the track work is now done. I used a rotary tool (Ryobi) with a 2" Tuf-Grind cutoff wheel, and it worked fine.

HOWEVER, if I were starting all over, I would certainly look into the saw that Gilly referenced above - like this one:

Alex

Attachments

Thanks for the suggestions everyone. I'll check out that saw.

Thanks for the suggestions everyone. I'll check out that saw.

Thanks for asking the question WJP.

In recent years I have trouble holding a dremel steady, even bracing my hand against something. That saw looks like a dandy idea for the hand tool impaired. ;-)

Thanks Gilly and Alex

Hmm..

I lay down Atlas flex, using screws as I go and make my curves and just cut to fit in place with a dremel cutoff disk. Not at all hard.

I also don't use those Atlas flex track tie joiners. There's not much point to them. I just trim off the ties when needed and use stained wood ties to fill in when necessary. The plastic tie joiners are pretty pointless when the track is screwed down anyway.

I ordered the Harbor Freight saw that Gilly referenced, but it doesn't come with a blade. What type of blade would you recommend for cutting Atlas track. This is a 6" saw with a 7/8" arbor.

Thanks, Mike

I'm a big fan of the Rotozip. It's basically a Dremel on steroids. Handy for cutting thin metal and also makes a great trim router.

If you love to have an excuse to buy a new tool, then by all means go for it. For my money, a cordless Dremel is a must have and has made every cut I needed on a large layout of all Atlas track.

Art

One of my co-workers told me he cut atlas three rail track on our table saw with a standard carbide blade- I tried it and it works great- just feed slowly and use a top board to keep pressure down on the track. You will get very, very, smooth cuts with almost no burr. I try to get in between ties, but if not it takes the tie and all.

bardo

The rotozip some times will get away from me so I like the regular rotary Dremel with large cut off disc.

If anyone is going to use a dremel or other rotary tool to cut track I strongly advise you also invest in and wear a full face shield. When a disc explodes at 20,000 + RPM (and they do) you don't get any second chances.

Mark

Here. Here! Mark.

I have been to the emergency room twice... both on a near miss that only scratched the eye. Both times I was wearing safety glasses with side shields, you need the full goggles!

After that no problems.

I like the newer Dremel cut off disks. They are a bit more robust than the older style. I have yet to have one of the newer disks come apart.

I like the newer Dremel cut off disks. They are a bit more robust than the older style. I have yet to have one of the newer disks come apart.

Yep! That's what I use. Goes through track like butter.

I went back to this post and then found a Harbor Freight store near my home.

I didn't have a lot of track to cut, but for the price of the saw and a few blades I had to give it a try. I have a dremel, but cutting all 3 rails straight was always a problem. This saw worked great, was quicker than the dremel (which I will keep for MANY other tasks).

Thank you for the recommendation! Terry

Terry,

What blades did you get? Do they work well? Thanks.

Ron

Gilly,

Thanks

Ron

Since I will be making 100s of cuts by the time I'm done, I ordered the cut off saw, disks, and a face shield yesterday. Maybe it will help me get started!

Ron