A lifetime supply.![]()

I just wrapped painter's tape on both side of the place I wanted the cut to be (thick). Then, I screwed it to a board, and went at it with a hacksaw. Then, I hit it with a file to smooth it a bit.

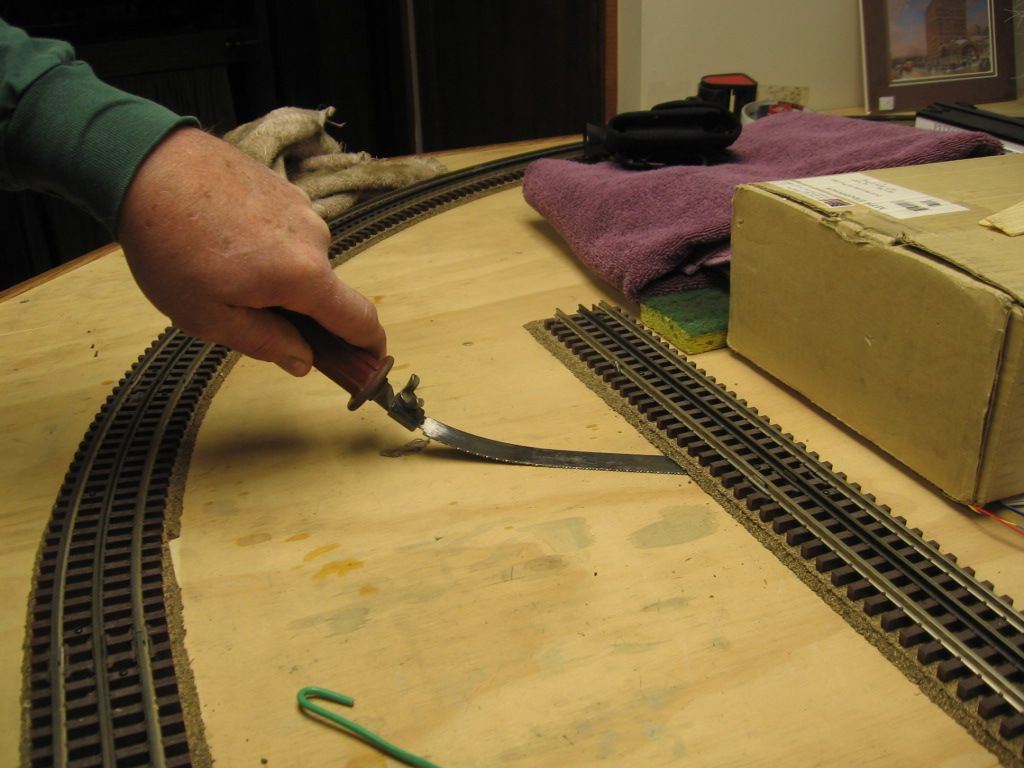

I use to use Dremel now I use this, it has a thin cutoff wheel on it. Nice straight cuts, when the track is down and ballasted. Sure makes it nice to add a turn out. When cutting loose sections make sure the track is held secure. I use a piece of homasote and a big steel block (10lbs) on top of that, a sand bag works well also. A vise will bend the rails.

Clem k

Attachments

Dremel has a video here; it's the first video listed. It concerns cutting HO track using a Dremel vice to hold the track; but, it does have several good pointers, including using the highest speed available, light pressure, larger cut-off wheel, etc.

And be sure to use eye protection.

Curious; what track are you cutting? The typical poster is cutting Gargraves flex track and that's the only kind I have experience with.

Hi Carl, I have both Gargraves flex and rigid track that I am going to be cutting Thanks for your advice.

Jim

WOW ! What a super response to my question. I never thought there would be so many different ways to make good cuts on track. And yes, as many of you suggested, any time I am using any method to cut metal, I use safety glasses.

Thanks so much for all of the responses to date and those yet to come.

Jim

Safety meeting of the day. These fiber re-inforced abrasive blades used to cut metal track require appropriate eye and possibly even face protection. Worst case is a blade coming-apart. Large hand-held grinders/cutters like the one pictured above and the bench sander I pictured would have similar issues. Be careful. IMO ![]() Mike CT

Mike CT![]()

Additional cutting tools.

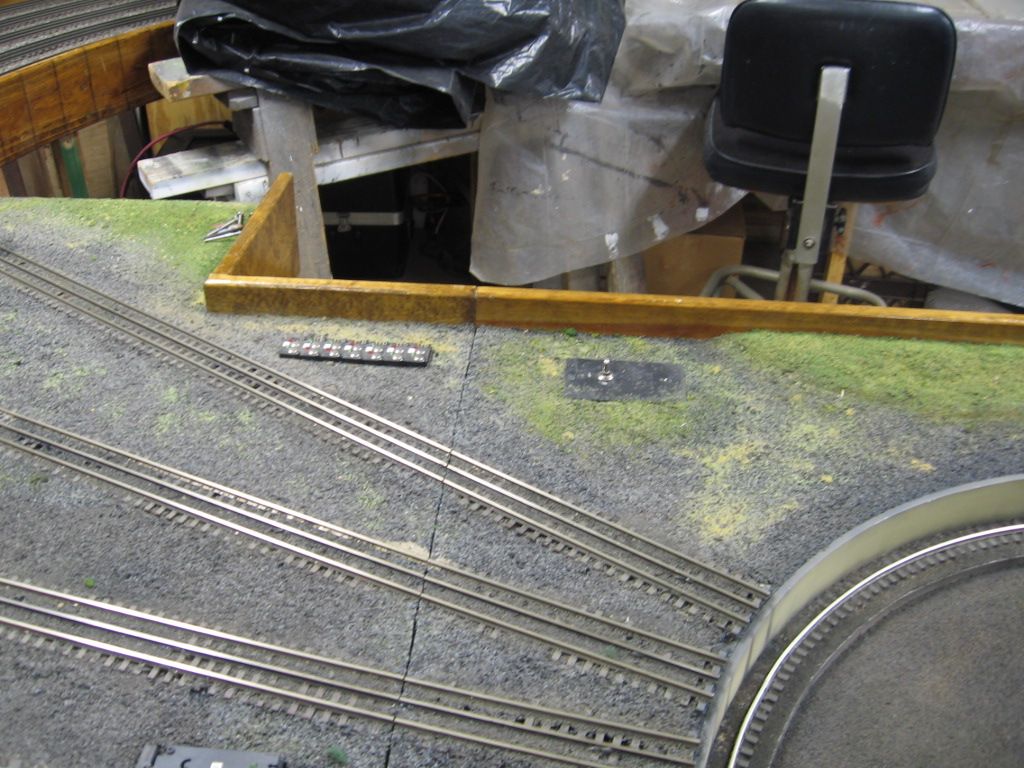

I used a Milwaukee Sawzall, (reciprocating saw), and the handle that adapts to the Sawzall blades to make an unusual cut on the Fort Pitt Hi-Railers Turntable module(s). We spaced the modules apart the thickness of a Sawzall blade, installed the track and then cut the track/ties. Note: These blades cut on pull not push, like a hacksaw. There may be reverse cut and abrasive edge carbide blades. I have used special Sawzall blade to cut holes in ceramic tile.

You have to look close, to see the cut between these two modules. Not only cutting the track but the plastic ties also.

Three module assembly.

Two of the three modules in my truck. The turntable bridge is in the box, bottom of picture.

Dremel 225-01 Flex-shaft attachment.

Mike, I find the right angle adapter is easier to use, I have that flex shaft, and it's rarely taken out of the box.

Mike, I find the right angle adapter is easier to use, I have that flex shaft, and it's rarely taken out of the box.

I agree, it was mentioned in a previous post, I added the link. ![]()

We've done this thread before, there was an off brand cut-off wheel that was larger, may be 2 ", which solves some of the angle cut problems.

Looks like there are plenty of power options:

Dremel

Rockwell Bladerunner X2

Harbor Freight 6 in. 5.5 Amp Cut-Off Saw (light duty).

Good info!

RickM46@live.com

And now it starts.

I have in house a ROTO ZIP RZ 20 and a 4" drill press vise that I use to cut PVC for honey flow lines in my honey processing building. I use the 3" metal cutting wheel and it really likes PVC. Now, my question, has anyone used this tool, wheel, or vise for track cutting?? I am gonna try. What is your input, suggestions, and comments?

Tom

If cutting track manually with a saw blade (razor or hack saw), I find that using a small amount of "3 in 1" household oil makes the cut much smoother, minimizing any binding. Also, the teeth will not wear down as quickly.

I have now moved on to a larger gauge of railroading. (haha)

Attachments

Everyone has their favorite technique, of course. I suppose someone, somewhere has even used an acetylene torch to cut 3-rail track....why, I'm not sure, but human nature being what it is....![]() !

!

For me, I bought a Model 225 flex shaft attachment for my Dremel motor tool. It has a fairly small handpiece that has a diameter of 1".

Then, Gargraves recommends/sells a cutting combo for Dremel.....#93108, a 2-pack of Gyros 2" dia. reinforced cutting disks, and #83985, a Gyros 1/8" mandrel for these disks.

So, a 2" disk on a 1" handpiece allows a vertical cut of 1/2"....more than enough to go through O3R rails from most every manufacturer....including Gargraves, of course.

Well, that's what has worked for me....quickly, accurately, easily......and SAFELY! And, yes, Virginia, you MUST, MUST, MUST wear safety glasses/goggles when using this combo to cut rail!!

However, after about 50 cuts or more with the same first disk, I've found that in cutting the rail, the disk has also abraded to the point that...when new it did, indeed, measure 2" in diameter...it now measures 1-3/4" dia. (now only allowing a vertical cut of 3/8") But because of the inherent reinforcement within the disk, it maintains its integrity, and continues to cut efficiently. I'm not cutting much rail anymore.....the layout is fairly complete trackwise...but were I to find the need for many more cuts, I would probably replace the disk with a new, full-diameter disk in order to keep the cut vertical.

Works for me. ![]()

KD

RickM46 posted:Originally Posted by CRH:Looks like there are plenty of power options:

Dremel

Rockwell Bladerunner X2

Harbor Freight 6 in. 5.5 Amp Cut-Off Saw (light duty).

Good info!

RickM46@live.com

And now it starts.

I have used this harbor freight cutter making many cuts on atlas track. works great.