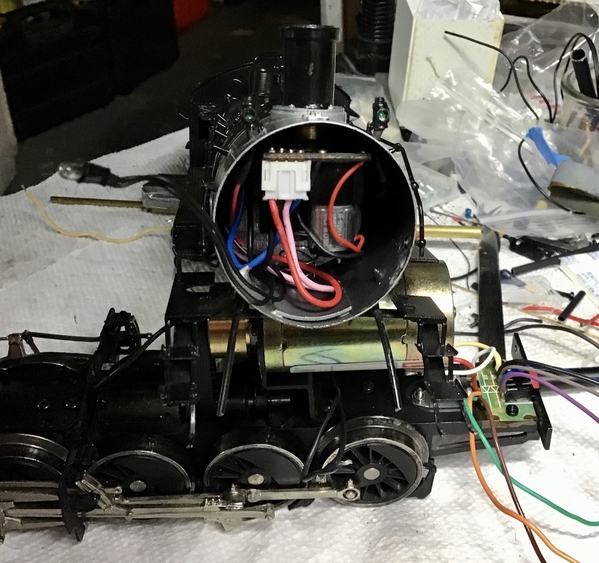

Not too long ago I picked up a 3rd Rail 4-8-2 Water Buffalo and a brass Williams Southern 4-6-2 #5013 that I would like to put ERR in. I would like to pickup a Cruise Commander and Railsounds Commander, maybe GRJ's chuff generator also (if possible/needed? not sure) and install myself - alternatively I could get in touch with a repair center and see if they could do it.

I have read around here on the forum that installing ERR is pretty straight forward. I have also heard that with MTH locos they require substantially more work to convert from DCS to ERR than other typical locos. While 3rd Rail/Williams are of course not MTH/DCS, are there any potential issues that might make the conversion more challenging, especially for a first-timer?

Also, is soldering required? Highly recommended? Can do without? I would need to buy the proper tools if yes, but better to take these things apart only once!

Hiring someone to do it would be the easier option, however I am interested in learning how to maintain and repair/upgrade my own collection. Then there is the cost, I understand that paying someone to do this is not cheap. If I have the option of paying someone to do the install, or pay the same amount to buy a new locomotive, I will almost certainly buy a new loco! ![]()

Thanks for the input!