Thank you eveybody for the encouragement and advice!

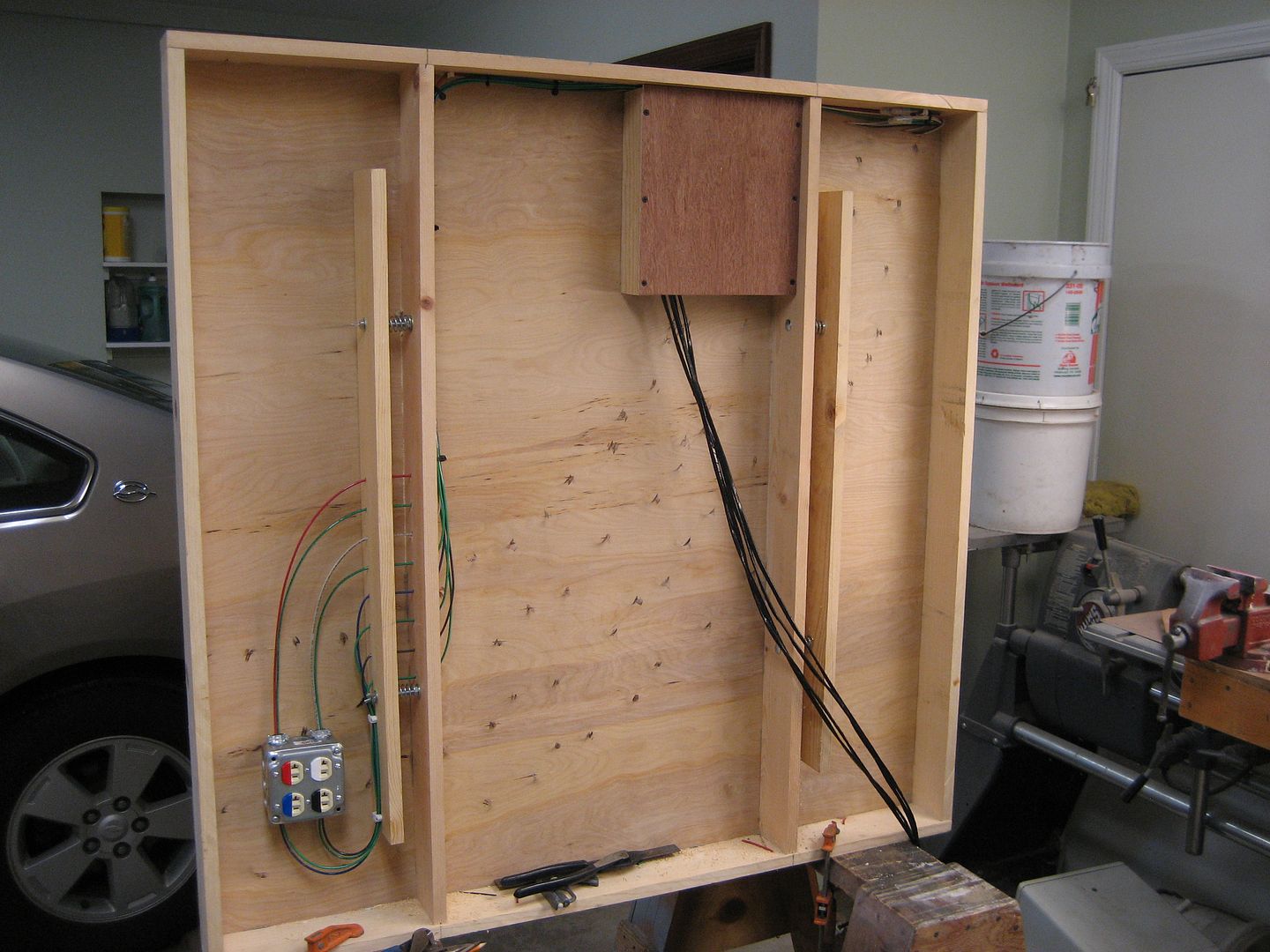

In general I have an order of operations question/dilemma. As you can see from the picture above I have sectional track and switches laid out with gaps where cut sections of track need to go. I would like to cut the sections of track and assemble them to the rest of the track/switches to check clearances/run trains and make sure the layout works operationally.

Is it a mistake to do that and then disassemble the track, come back and paint, glue roadbed down and screw the track down permanently?

Hey Michael,

No mistake at all, what you are planning on doing sounds perfectly fine to me. I'd do it that way, too.

A few extra tips to consider that I can think of right off hand.........................

You might want to temporarily fasten all your switches and preformed track in the picture down to the layout surface, so they can't slide around while you're cutting the flex track to fit in between. You might try using small nails, staples, or screws placed up against the sides of the rails and ties. With screws, you could also employ steel or thin wood washers. For nails or staples, don't hammer them all the way down, you will need to be able to pull them out later. CAUTION: Be extra careful if hammering close to your rails, these hollow formed rail sections will dent very easily! Denting the rail on an expensive switch will not make your day!

Start out by fitting and cutting your longest piece of flex track first. That way, if you mess up, you can re-use this piece at another slightly shorter area and won't waste hardly any track in the process. Besides, the more pieces you fit and cut, the better you will get at it (it won't take long  ).

).

Having short pieces of fitter track makes good track alignment hard to do. In some places you probably can't avoid it. But for example, if you have a space requiring one full length of track and another only a few inches long, then consider cutting one piece of flex track in half and another piece slightly over a half in order to span the full gap. This will make track alignment much easier in these areas.

If needing fitter pieces in curved areas, pre-bend the track to the proper radius before cutting the fitter piece. The shorter the fitter piece, the harder it will be to bend it smoothly after it's been cut.

Once all your track cutting and fitting is done, you can hook up some power to it and run some trains over it to check out operation. Or just roll some freight cars over the track and see how they behave. Or you can simply eyeball it and make sure all the curves and straights flow smoothly together with no kinks anywhere. Once satisfied, it's time to get ready for roadbed. Mark the outline of all track pieces, then remove track in areas where you can start laying road bed. Don't paint anything yet - you'll cover all your marked outlines!

That's it for now. Once all your track outlines have been properly marked, laying roadbed is really quite easy. You don't have to be near as precise as cutting and fitting track.