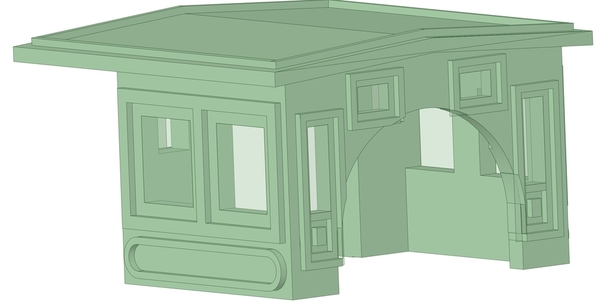

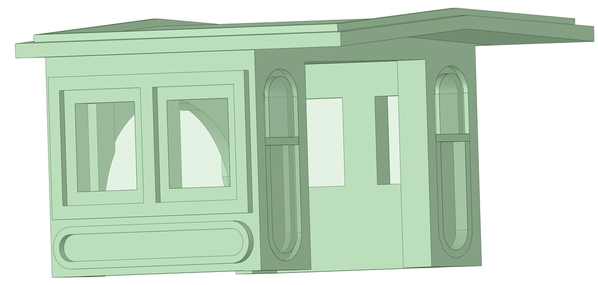

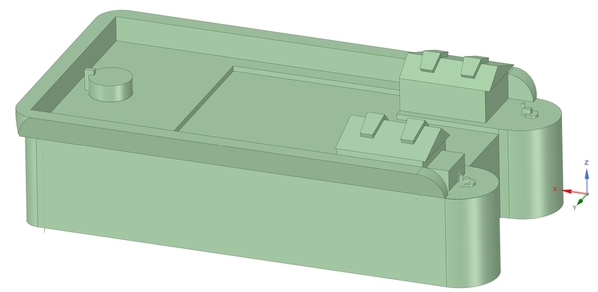

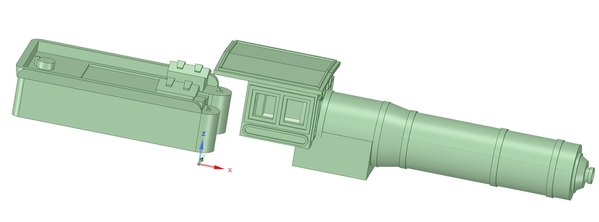

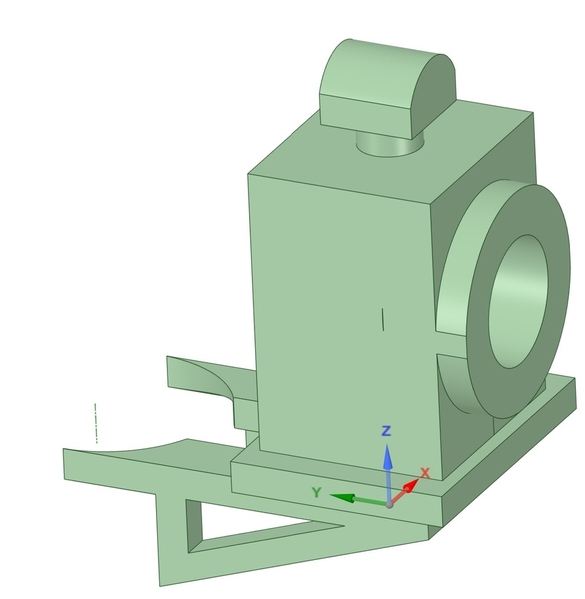

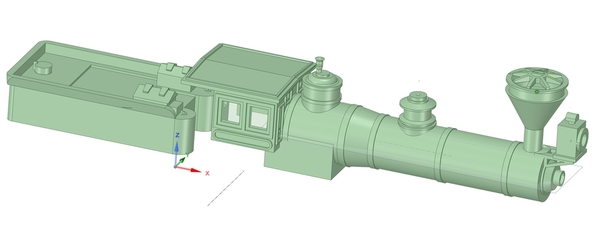

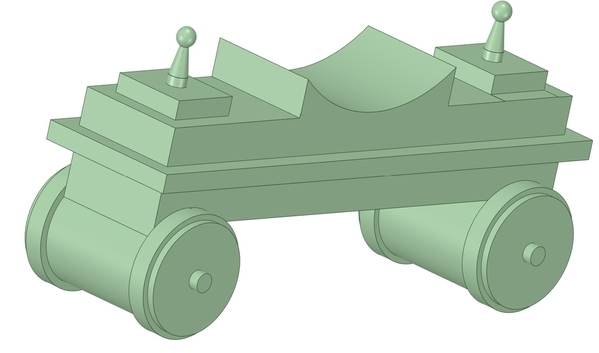

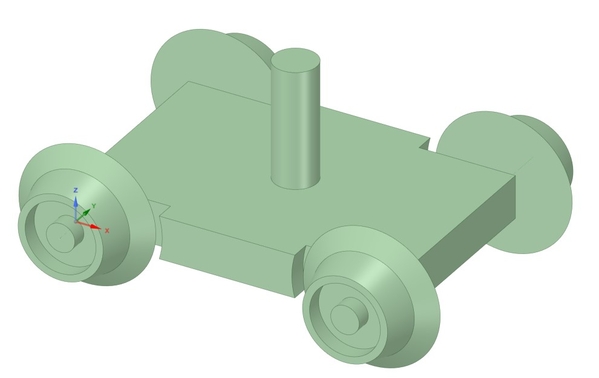

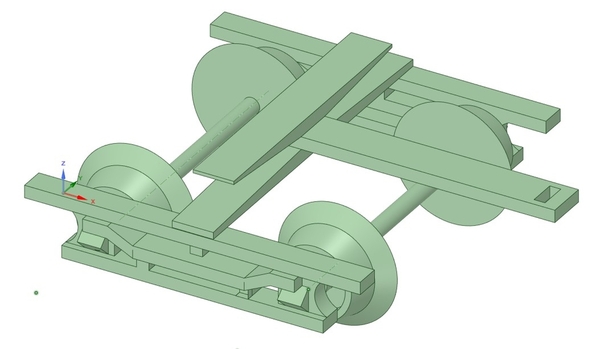

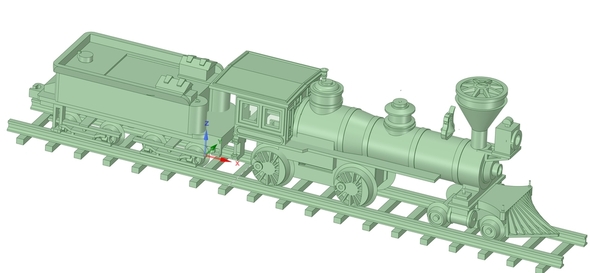

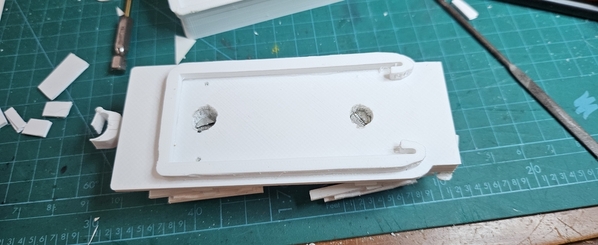

To update everyone, I finished the main drivers this past weekend. This includes modifying the Lionel Trolly to have the scale wheels and then modeling that inserting it into the overall model.

The getting the wheels on took a lot of trial and error, but I'm happy with the results.

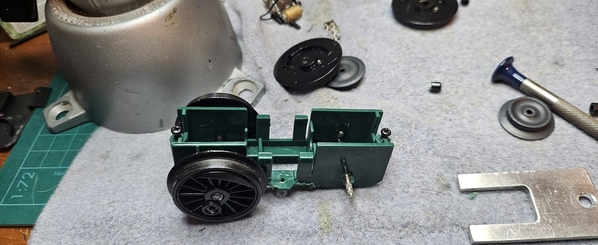

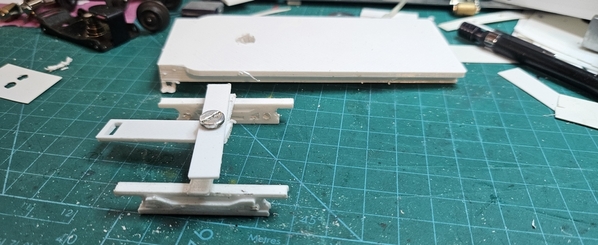

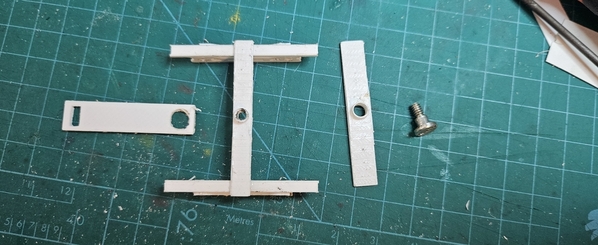

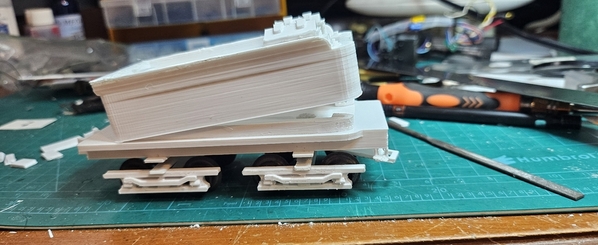

First, I stripped the trolley and prepared it for the new wheels (sorry for the pictures in portrait mode):

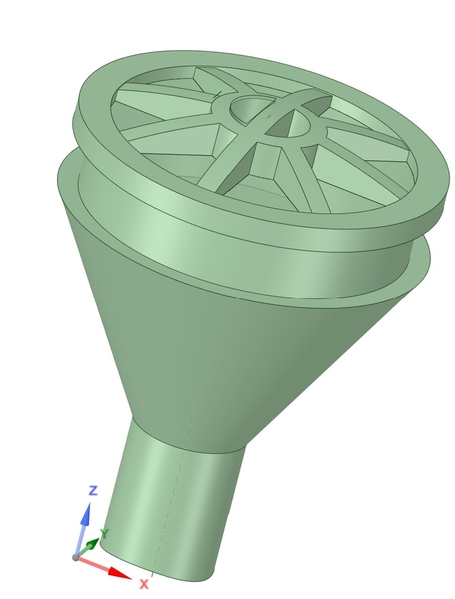

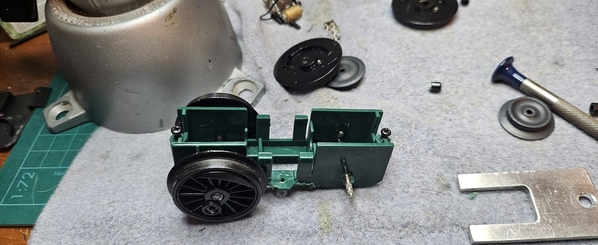

I then installed the non-motored wheels by drilling out the existing axle holes to a size that will let me use the standard axle from the donor engine:

When I drilled out the holes, I had to get rid of the spacers to keep the wheels in line. I used a couple of washers on each side to space them correctly to remove the sway.

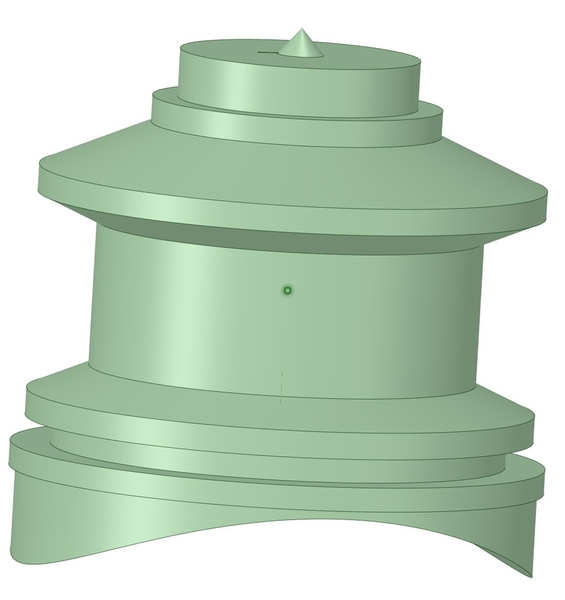

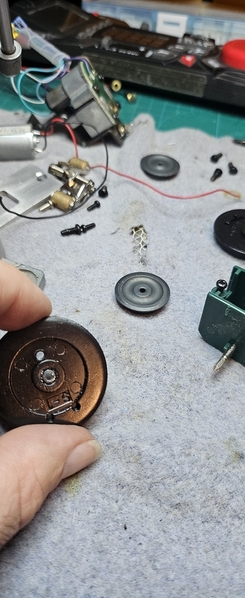

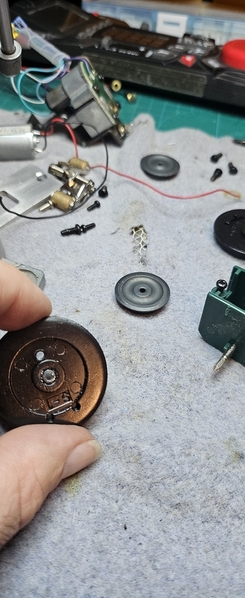

Now on to the powered driver - this one was much more difficult because I had to use the existing axle as it had the gear on it.

What I decided to do was to cut the correct sized axle and then to drill the correct size in it for the trolley axle. The sized needed was 3/32. The two problems I had were centering the hole and not breaking the drill bit (I only went through 2). To center the hole, I inserted the big axle a little way into the wheel and then used the largest bit I could fit to drill just enough to give me an indentation to use the small bit.

Then I drilled the hole with the 3/32 bit.

Then I pressed them on. This is the delicate process because the small axle does bend (mine did). Once on, I did my best to get rid of the wobble and I was able to enough for my satisfaction. I also made sure both sets were quartered the same direction.

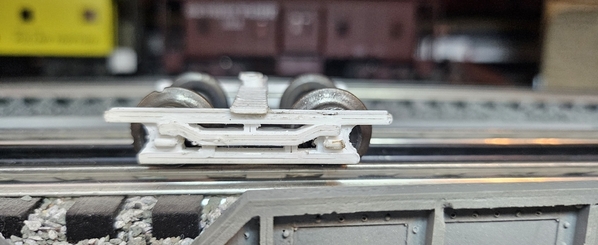

I made sure to test it with the motor out. I did this by checking the width with the U-tool in several of the pictures above. Then I put it on a part of the layout with a ramp letting it run free down the ramp into a Ross 4-Way Yard Switch doing an "s" curve into one of the middle tracks. It ran smooth and stayed on the track.

I know the model I based this on has a smaller counter weighted driver wheel, but I'm fine with mine having it larger - it would be too hard to get make them smaller using a Dremel...

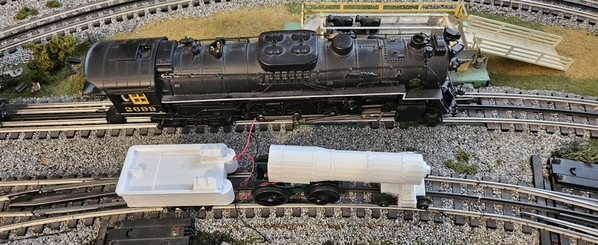

Once tested, I put in the motor (you can kinda see the washer spacers in the top set of drive wheels):

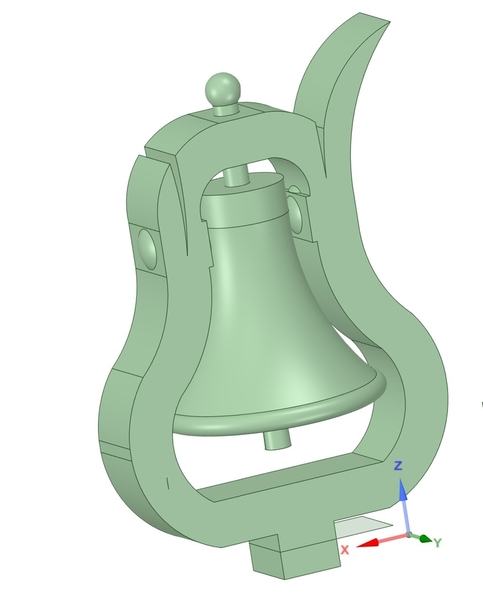

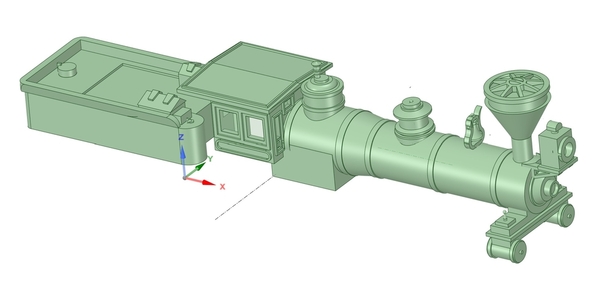

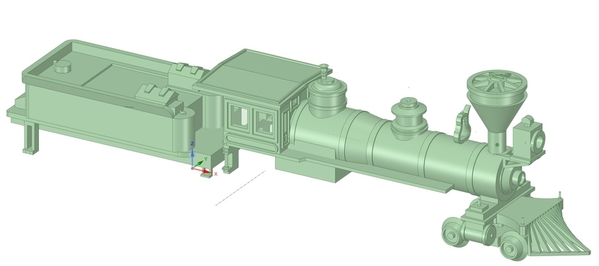

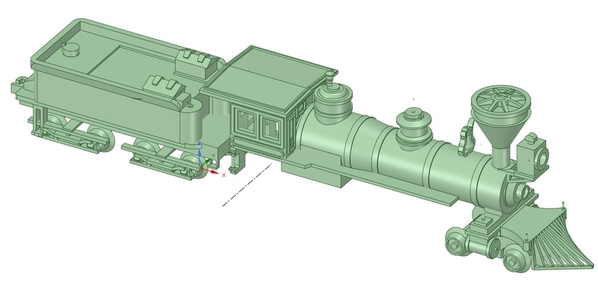

Lastly, I tested it using an HO Transformer and it ran great, so I was ready to model it and put it on the combined view.

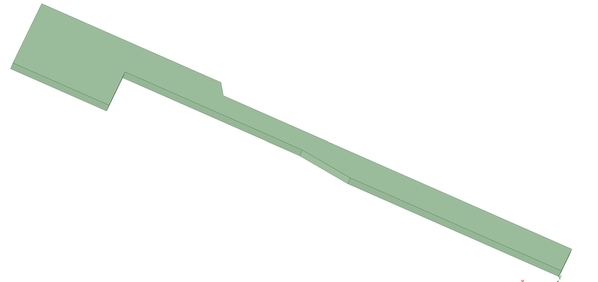

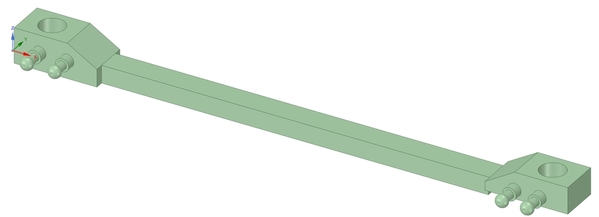

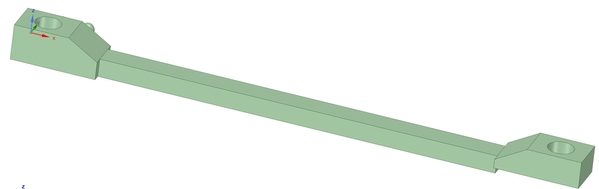

I also modeled a piece of track for perspective. The track above is 15" long, so this is a small engine (as I expected).

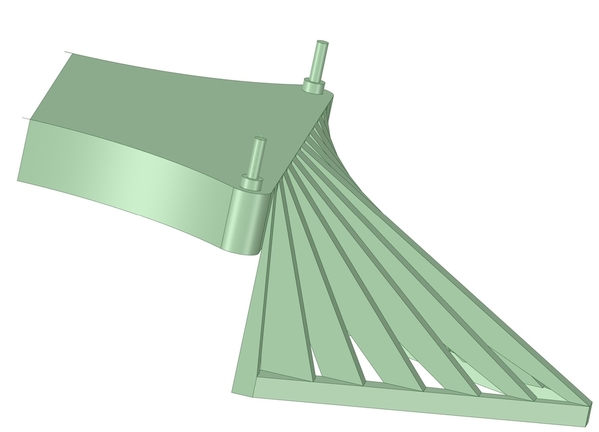

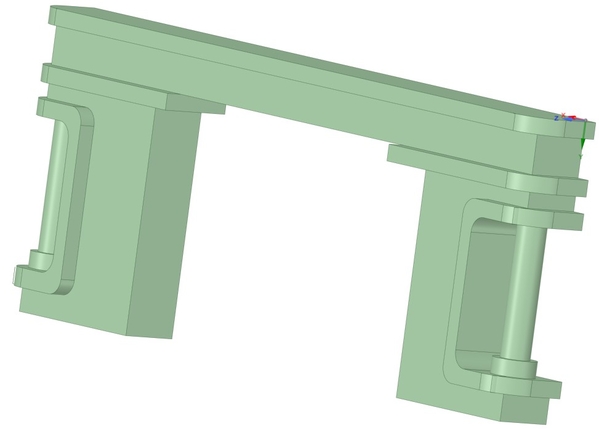

I won't do much the rest of the week as I'm going out of town, but the next steps are the rods, finishing the frame, and adjusting the boiler for the drive wheels to fit without overlapping.

So almost there!!