If you were on the supply side of the 0 scale hobby and you were going to make 0 scale turnouts, considering the market place as it is, what would get your attention? Where would you place your emphasis? tt

Original Post

|

|

If you were on the supply side of the 0 scale hobby and you were going to make 0 scale turnouts, considering the market place as it is, what would get your attention? Where would you place your emphasis? tt

Replies sorted oldest to newest

quote:Originally posted by Old Goat:

...it would need to mate perfectly with the best selling brand of flextrack currently on the market.

Matt

quote:Originally posted by Old Goat:

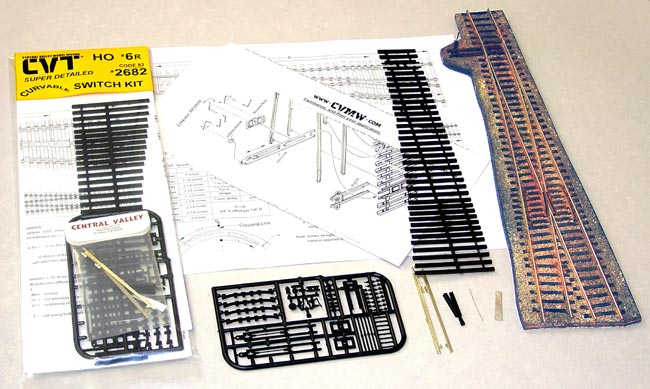

Any interest in an O scale turnout kit similar to those offered by Central Valley Model Works to those How Ordinary modelers?

Matt

quote:Originally posted by CBQer:

#6 matched to Atlas track AND #6 for 125.

Dick

quote:Originally posted by Casey Jones2:

What's a "turnout" anyways??

quote:Originally posted by Tom Tee:

What features would it have?

What features would it not have?

quote:Originally posted by CBQer:

dear flanger,

A turnout is a switch. So we don't confuse a switch (electrical) we tend to call it a turnout as one turns off the main to a different track.

Dick

quote:Originally posted by reutling:

Gents,

I believe that what you are calling Atlas-Roco, Atlas had nothing to do with those two piece #6 switches. I believe they were just plain Roco.

Correct

IIRC Roco also had a line of cars, which had nothing to do with Atlas.

Not correct; Roco has never, regrettably, manufactured 0 ga cars other than the "Atlas" ones. [ Strictly speaking, they have manufactured 0 scale cars: the ex-Fama 0m narrow ga cars ].

Roco also made a line of track, which is larger r than Atlas 24"r.

Other than the #6's, the only non-Atlas-origin 0 ga track Roco has manufactured are 3 ft sections of flex track with the same sleeper spacing as the #6's; this is not the same tie section as the Atlas 3 ft section. Roco did catalogue the Atlas 24" radius [ as "radius 609.6 mm" ] curves and full straight sections under their own p/n's in Europe.

The larger radius track referred to may be the Rivarossi sectional curves, which were about a 32 inch radius, and used a much smaller rail section, perhaps about code 100.

Ed Reutling

quote:Originally posted by fredswain:

I'm not sure what radius this is but it's decently tight. The box does say Atlas and made in Austria.

Access to this requires an OGR Forum Supporting Membership