Adriatic, good explanation. As I said, I was just commenting that "technically" there has to be a power loss, albeit minimal, using multiple wires for the bus. ![]()

Anyway, I don't know how the layout is currently wired. One photo shows the transformer in an access area in the center of the layout, presumably with power going from there to multiple points around the layout. I don't know if he's using FasTrack terminal track(s) or some other connection and what size wire. But, my concern is that none of this wiring discussion makes much difference if his stalling problem is not related to power distribution. He can move the transformer, rewire using block or bus wiring, use whichever connectors he wants and the signal will still be blocked. My guess is rebuilding the tunnel without the chicken wire will resolve the stalling issue.

I actually think he could simply:

- move the transformer to wherever he wants it

- put the MTH terminal strip where the transformer is now

- connect the current track wires to the terminal strip

- run the main wires from the transformer to the terminal strip

I'd still like to know how the layout is currently wired. If power is not the issue, then why rewire it just to relocate the transformer?

Fine points Dave. I placed moving the transformer so low on priority I more or less dismissed it. The terminal block would certainly save effort there.

I assumed with new curves going in the track issue would be cleared up on it's own, but looking at the pictures more ....(unavailable some days as Android is so hit and miss. E.g. Today I can't do anything but post, no likes, no quotes, no attachment tool, and no thumbnail views.. pictures MUST be in the text 90% of the time, likely no search as well considering the others issues. It may clear up later; but usually clears late Sunday night).... I can see the issue could be on straights and remain. That conventional test sure would help narrow it down and save a lot of unneeded speculation.

I guess we'll see what Flemming has to say after he's had time to digest all this. ![]()

Going from O36 curves to O48 curves will mean most track has to be moved, so rewiring is not a bad thing. I just don't want him to spend a lot of time/money on connectors, etc., if a complete rewire is not going to fix the stall issue anyway. From what I can tell, except for the stall, the layout works the way it's wired now, so why not take the easy route and just move things around a bit?

Me too. I tend to, squeek so cringe at opening someone else's wallet ![]()

Sorry about any nonsensical text. I really don't have much control over it. What should take seconds to type can take many minutes thanks to Google being so "smart"and eager to help even when off. My dogs nose does better text corrections ![]()

DoubleDAZ posted:rtr12 posted:I don't know about the correct 'bus' terminology, but FWIW, I would consider the two examples in your picture to be identical in function. Nice drawings, BTW...still done in SCARM? (I finally broke down and purchased SCARM so I could view all your (and others) track plans posted around here.)

Thanks and yes, the diagram was done in SCARM though it would have been easier in RR-Track.

As far as functionally goes, I suspect either type of connector and wiring scheme would work. However, doesn't breaking the "bus" wire into multiple segments reduce conductivity? Maybe not enough to affect operation, but still a reduction? I always thought the idea behind bus wiring was to use a single wire so the signal would be stronger over a longer distance.

FWIW, I believe you would have been able to open any file in the trial version of SCARM, you just wouldn't have been able to make changes if the track count was more than 100. Always happy to see someone support Mixy's efforts though and I'm sure he appreciates the support. Now you can convert your design to SCARM and maybe play with some expansion ideas.

Well at least you know what's easier in what program. ![]() I still struggle with both, although I haven't been into either one for a while now. Last RRtrack session it crashed on me and I just closed it down and quit.

I still struggle with both, although I haven't been into either one for a while now. Last RRtrack session it crashed on me and I just closed it down and quit. ![]()

I suppose you have a point about the 'bus' being continuous, I'm really not sure of the exact differences between the two methods? Maybe I'll look around a bit, I am now a bit curious about this. Probably way to technical for me, EE type stuff, but I'll see anyway...

I got SCARM somewhat for viewing others plans posted here, some for fiddling around with it, and also for support of a good product. I don't recall ever crashing SCARM either? I would hate to see Mixy lose interest and stop developing the program. And I went back later and got the train running thingie... ![]()

Edit: I think my questions have been answered above, in Adriatic's post. I should have turned the page before replying...

rtr12 posted:Well at least you know what's easier in what program.

I still struggle with both, although I haven't been into either one for a while now. Last RRtrack session it crashed on me and I just closed it down and quit.

I think I crashed SCARM once when I was beta testing the simulator way back when, but the RRT crashes are really irritating. You won't believe how much I struggle using RRT yesterday because I've gotten so used to SCARM. I find myself trying to do things the SCARM way and get all sorts or weirdness. ![]() Both are definitely programs you need to use often to stay proficient.

Both are definitely programs you need to use often to stay proficient.

I want to be able to run both my TMCC and LEGACY Engines around the hole layout without both engines stalling I don't run them at the same time

Hi Guys, been following this discussion for a few days. All are very good suggestions submitted by you and presented to the readers in a down to earth manner that is easily understood. I need that!!! I do have one item I'd like to add to this post. You guys have covered very well getting wiring from the xformer to a terminal strip for one type of layout and also bus wires to take power around an layout. You discussed items(methods) to join bus wires to track feeder wires. Now can someone chime in to offer ideas for some good methods to connect my track red & black feeder wires to my track. OK guys, the best method or ideas to join feed wires to my GG track. Convenience, ease of installing, is important and I had rather spend a couple of bucks to save a couple of hours. I need to go thru my plyboard and homosote(sp) top. Hey you guys know what I mean.

My best regards

Tommy

First, I am not all that familiar with Gargraves track (I use Atlas).

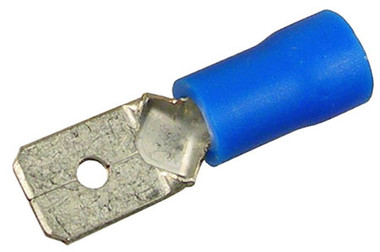

However, I believe some folks use this type of quick connect and stick them in the slots in the bottom of the rails. These are just a couple of pics I found, one insulated and one non-insulated. You would need to get the proper size to fit the wire size you are using. Using the proper crimper is highly recommended if you are going to crimp as your only method of fastening. Many people using these connectors crimp and then solder the wires for best possible connections (crimper is not as important using this method).

Gargraves may even have some type of connector like this that they make for this purpose? I think they do have some type of stuff that slips in the bottom rail opening. Others that use the track can probably explain further.

The only other method I know of for that type of track is soldering directly to the track. This is the preferred method for some folks around here. Hope that helps you a little.

I prefer to attach the drop wire to the track, leaving the end bare, allowing a smaller hole than adding any fitting. The color here may be chosen to hide vs red or whatever. Then tie the drop in underneath. I've mentioned connection methods already.

One thing not mentioned is screw terminals with square wire grip plates (a square washer) are preferred imo; you don't need a circle connecter crimped on them.

flemming posted:I want to be able to run both my TMCC and LEGACY Engines around the hole layout without both engines stalling I don't run them at the same time

The conventional test is just to confirm the track receives power while under load. I do not expect this to clear up the tunnel. I expect a wire added to the home outlet ground and into the tunnel for that.., be it temporary or permanent as there are other ways to do this, incuding the buffer .... Or new mountains. This is just to address the issue outside the tunnel.

Here is my thoughts...... I think the one spot outside may have bad track. The signal or power is stopping there. Connections are the first suspect, the ground plane second. This requires a test in conventional to prove power first. The the ground wire to begin to address the signal.

The track past it is getting power through the tunnel, but the signal stops in the tunnel.

So it stops from a power issue in one place and stops from a signal issue in the other.

But new mountains are not necessarily the cure either. We have not confirmed that is the issue, just guessed. Run the ground under the tunnel.

If the chicken wire is exposed, attaching the ground wire to the chicken wire could turn the chicken wire into a big antenna. The chicken wire should not connect to any other circuits.....which is likely how it is, but I didn't build it.

I use fastrack

Are you using FasTrack terminal tracks now?

flemming posted:what AWG wire should I use

AFAIK, traditional guidelines for this size layout would suggest 14awg from the power supply to the terminal strip and then 16awg from the strip to the tracks. From what I see though, the layout seems to work fine with whatever size wire you're using now especially if you only have 1 set of red/black wires from the transformer to a terminal track.

I like Dave's suggestion above. Pretty much what I have on my layout. Layout is a little different, but it works just fine here.

thank you very much for the info