I agree with Gandy that a used Hobby Horse press is going to be less expensive than new one.

However, the Lionel ST-350 rivet press, tools, and Lionel wheel cups are sought by both repairmen and collectors. Therefore they tend to be rather expensive. A new Hobby Horse press would almost certainly be less expensive than an ST-350 (but you could get lucky)

If you decide to go for a used Hobby Horse press, be aware that the press evolved over time.

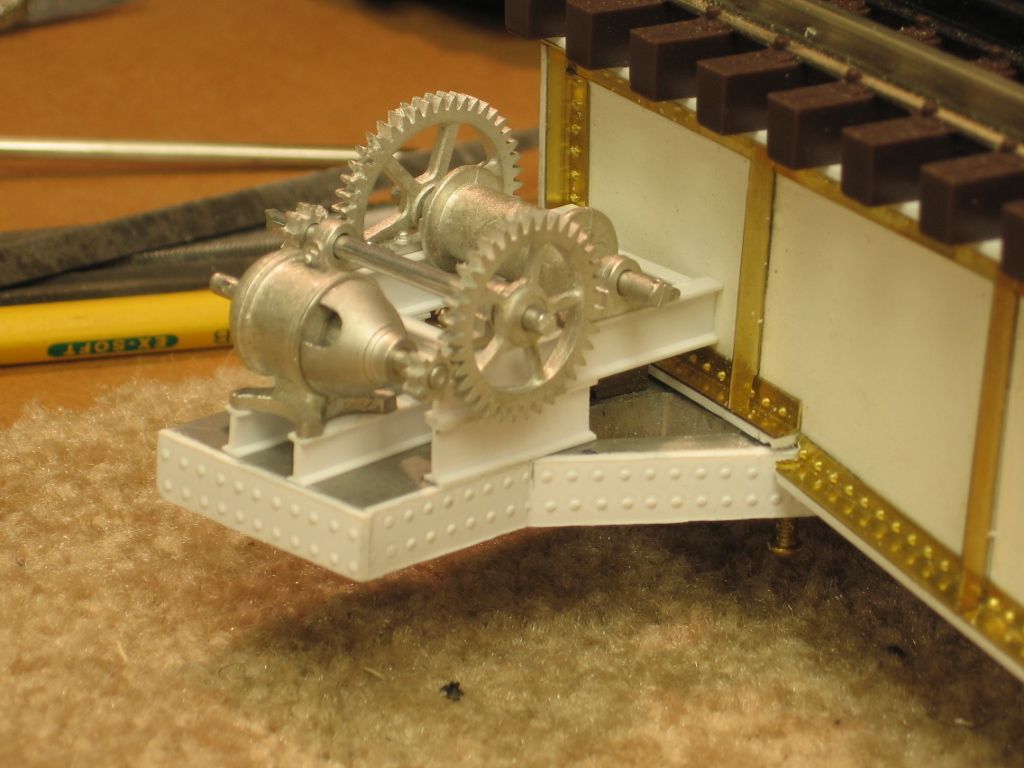

I use one of the custom presses that Hobby Horse made up for Lionel.

I imagine most folks acquire their outfit in a fashion similar to how I did.

I started with the press, 15 piece tool set, and 10 piece wheel cup set. Then I added pieces gradually, sometimes buying items when needed, other times just picking up the latest new tool from Hobby Horse at York.

In addition to the basic tool set, Train Tender had some custom tools designed and made. (I have most of them)

These guys make some custom items too: http://ttrponline.com/

(I have a couple of pairs of their wheel cups and a couple of their custom tools.)

I have no experience with their press or basic tooling.

I often find that these special purpose tools are the best choice for jobs other than the purpose for which they were designed.

Unfortunately, with a few exceptions, the wheel cups are single purpose. (but often the same wheel was used on multiple locomotives