Originally Posted by nycboy:

Sorry Stan but I got a question, You said before that when you put in the diode to the middle rail, It will reduce the voltage by half, are you sure this is correct? Ive read about voltage drop but i haven't read a topic that says a Diode will reduce the voltage by half

No worries. For model train electronics there a two relevant characteristics of a diode. One is they conduct current in one direction which effects AC to DC conversion. The other is they induce a voltage drop of about 0.7V. Note that there are interesting applications for diodes in communications for shifting frequencies of signals or switching RF signals but we're talking model trains.

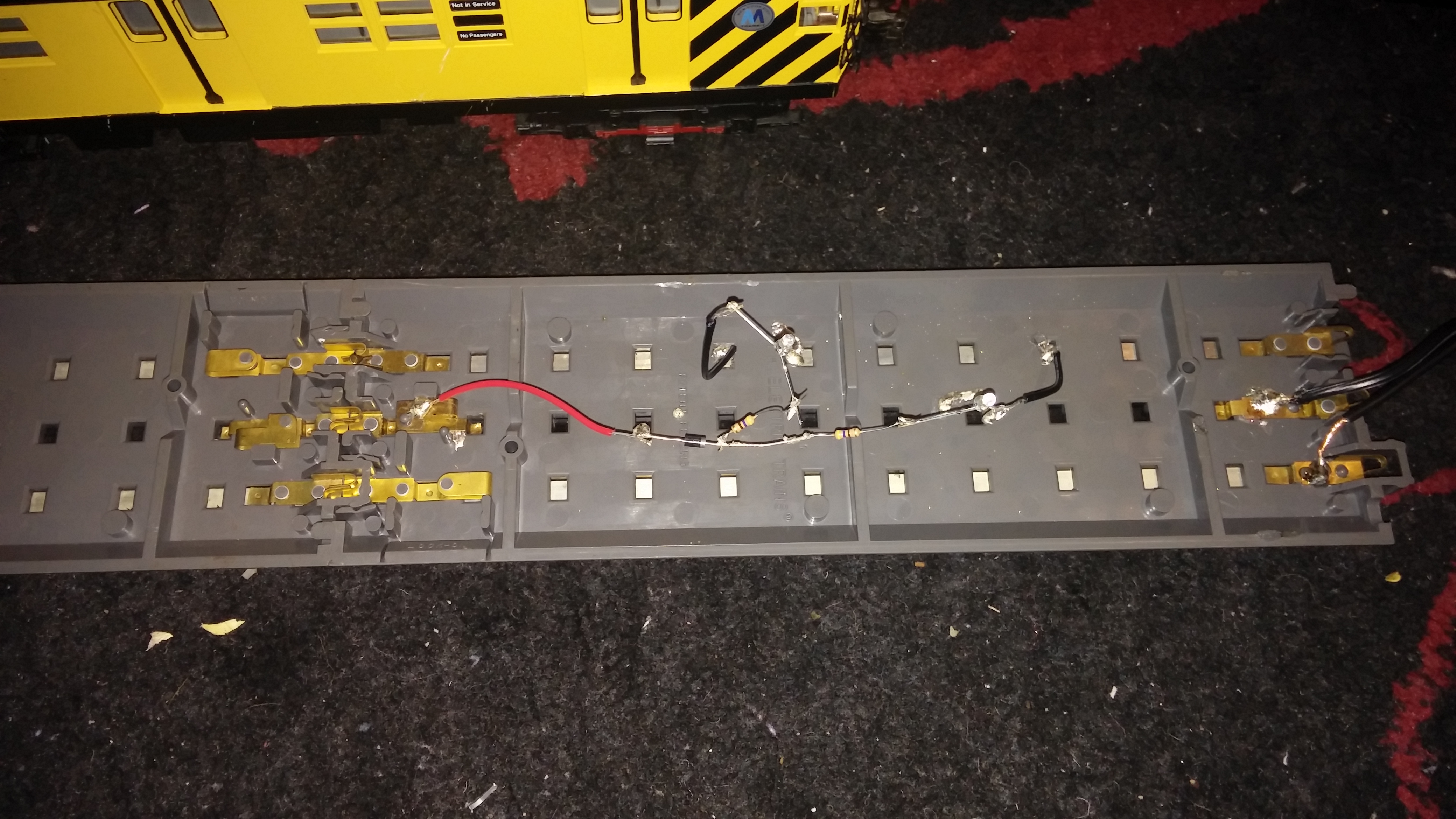

For the sparking application, by inserting a single diode as shown earlier, the current only flows on half of the AC line cycle. Look up "half-wave rectification" in your textbook. Then, because voltage is only available to the LED half the time, the effective voltage is cut in half. IF instead of a single diode you used a bridge rectifier, then current could flow on both halves of the AC line cycle and the voltage would not be cut in half. This would be "full-wave rectification".

In the sparking application, there is NO capacitor shown. If you inserted a capacitor after the diode, this would store energy during the intervals when there would have been no available voltage. So during the half-cycle when the diode could supply current to the LED, it would also charge up the capacitor. During the other half-cycle when the diode was "cut-off", the capacitor would step in and supply current to the LED.

You might need to think about this for a bit but you don't want to install capacitor in a sparking circuit for 2 reasons. First, if you are using track power, then the capacitor means you need to also add that inductor to deal with DCS signaling. Second, by leaving out the capacitor, the voltage available to the LED is more "choppy" and variable (the capacitor smooths the voltage). You want this somewhat random-like change in brightness in the LED for sparking. Note that the inventor even used a "blinking" LED presumably to make the sparking more random or hence more life-like (in my opinion).