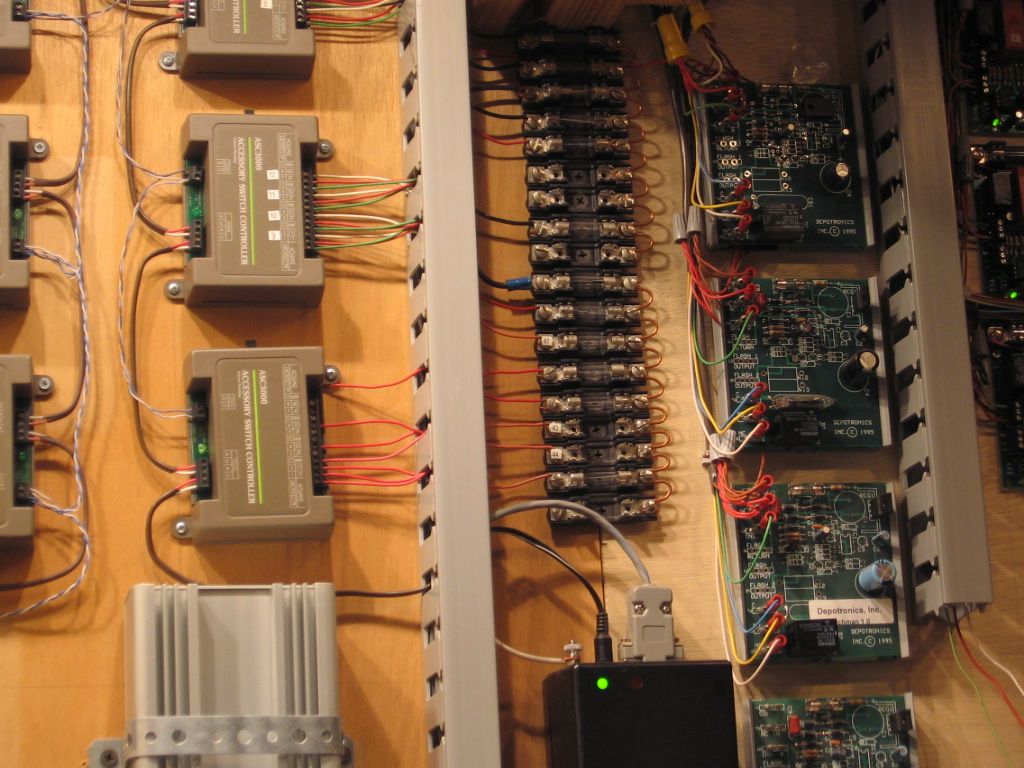

Each, Stranded v.s. Solid has it's advantages as listed. Most of the wiring in your home would be solid. Easiest, and most reliable termination. Solid wire is available through size #2. Sizes larger than #2 Solid would be hard to find. IMO, size #8 is when flexibility becomes an issue. IMO. Solid wire adds to neatness, and an orderly assembly, for the smaller size wires.

Edit/add (11/11/15): Note that equivalent stranded wire has a slightly larger diameter than the same size solid wire. Stranded would also have more surface area.

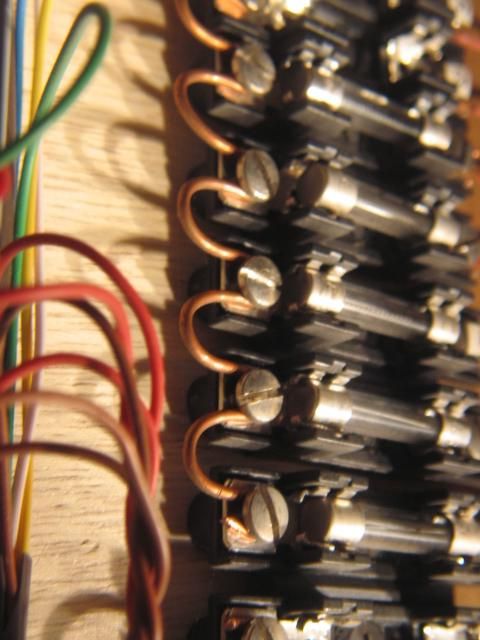

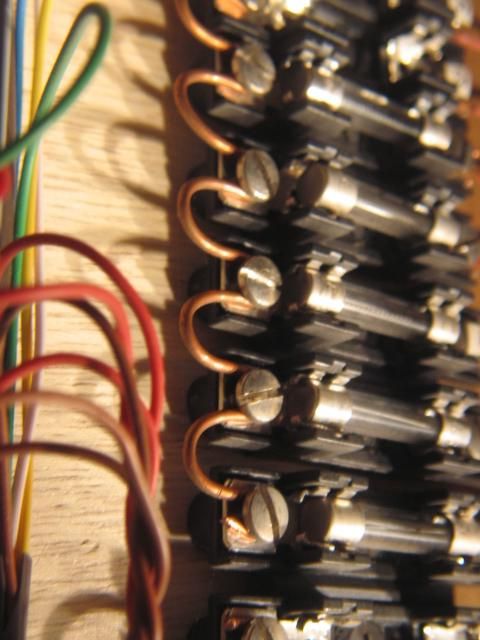

Difficult to do this with Stranded wire.

This truck termination probably would not last long if it was solid wire.

If you use stranded wire consistently, it's best to invest in good termination tools and the correct forked spade, or I-let connectors. Solid easily wraps around a screw, (Clockwise, please), or inserts in a provided termination, Stranded, IMO, should not be wrapped around a screw terminal, the appropriate crimp on termination should be used.

If you use stranded wire consistently, it's best to invest in good termination tools and the correct forked spade, or I-let connectors. Solid easily wraps around a screw, (Clockwise, please), or inserts in a provided termination, Stranded, IMO, should not be wrapped around a screw terminal, the appropriate crimp on termination should be used.

If you use stranded wire consistently, it's best to invest in good termination tools and the correct forked spade, or I-let connectors. Solid easily wraps around a screw, (Clockwise, please), or inserts in a provided termination, Stranded, IMO, should not be wrapped around a screw terminal, the appropriate crimp on termination should be used.

If you use stranded wire consistently, it's best to invest in good termination tools and the correct forked spade, or I-let connectors. Solid easily wraps around a screw, (Clockwise, please), or inserts in a provided termination, Stranded, IMO, should not be wrapped around a screw terminal, the appropriate crimp on termination should be used.