Just got a email from Lionel saying they had no idea when the new 180 watt power house will be shipped. We have a bunch on order with Charlie Ro, but need power now Z4000's are not the answer. Does anyone have a handle on a substitute system? We are using DCS so need something compatible with it and need 180 watt output.

Replies sorted oldest to newest

Why aren't the Z4000 transformers suitable?

You could pick up some post-war ZW's and add a modern circuit breaker.

Mike mentioned the shipping and arrival time during the LUG meeting at York. They are a 2016 item.

He may need more than 200 watts per channel.

I remember hearing what Moonman said from the video MartyE posted from the York meeting. I was also wanting to get a couple more PH-180 bricks. I have Legacy, but I run the PH-180's through my TIU for power and add the Legacy after the TIU. I was wanting to expand.

I don't know a lot about available power other than the PH-180's and I realize you have DCS and not Legacy, but would a ZW-L be suitable, just for power? I would also be curious about the Z4000 not being suitable as was GRJ? Although the ZW-L is a bit pricey for me, these were both options I was thinking about as well. Maybe I will just wait?

We are building a very large modular layout with 5 of what we call power districts. Each district takes 4, 180 watt power houses. Z4000's just don't work with the way we have the control panels set up, plus the cost is prohibitive. We are testing each power district with the four, 180 watt power houses we have. Every thing works great 10"s all over and enough amps to do what we plan. But we can't run but one power district. Don't want to mess with success, guess we will wait another ?? months.

We are building a very large modular layout with 5 of what we call power districts. Each district takes 4, 180 watt power houses. Z4000's just don't work with the way we have the control panels set up, plus the cost is prohibitive. We are testing each power district with the four, 180 watt power houses we have. Every thing works great 10"s all over and enough amps to do what we plan. But we can't run but one power district. Don't want to mess with success, guess we will wait another ?? months.

I sure don't understand your thinking, relative to the Z4000 transformers. Our layout has 6 separate power districts, 4 are powered by two Z400 transformers, while the yard & switching lead are powered by one Lionel 180 brick, and the steam engine terminal is powered by another Lionel 180 brick. Everything works well together, and we have never experienced any overload circuit breaker trips. The layout is DCS plus Legacy/TMCC and each output of the twin TIUs are protected with a 10amp automotive "quick blow" fuse.

In my opinion, if you can not obtain the 180 bricks, then use the Z4000 transformers.

He may need more than 200 watts per channel.

Uhh... Did you read the original post?

with it and need 180 watt output

Sounds like he wants 180 watts.

Several years ago I was faced with the problem of powering my layout qt reasonable cost. I found that Hammond makes a 18 volt 10 amp transformer. I purchased two of them for about $60.00 each from a local supplier. I use a lionel track lockon for its circuit breaker function. So far no problems nad much less expensive than a brick.

I would stay away from the Lionel track lockon because it is known to disrupt the DCS signal.

kgsouth,

Pick up a couple ZW's that have been upgraded, put some 10 Amp breakers between the ZW transformers and the TIU on every Red Channel, you will have the power you need.

I have 2 Z4K's 3 ZW's and 2 KW's that powered all my different layout thru the years.

PCRR/Dave

A ZW would be a good choice. Just keep in mind a post war ZW puts out about 180 - 190 watts total, so 1 ZW = 1 PH180.

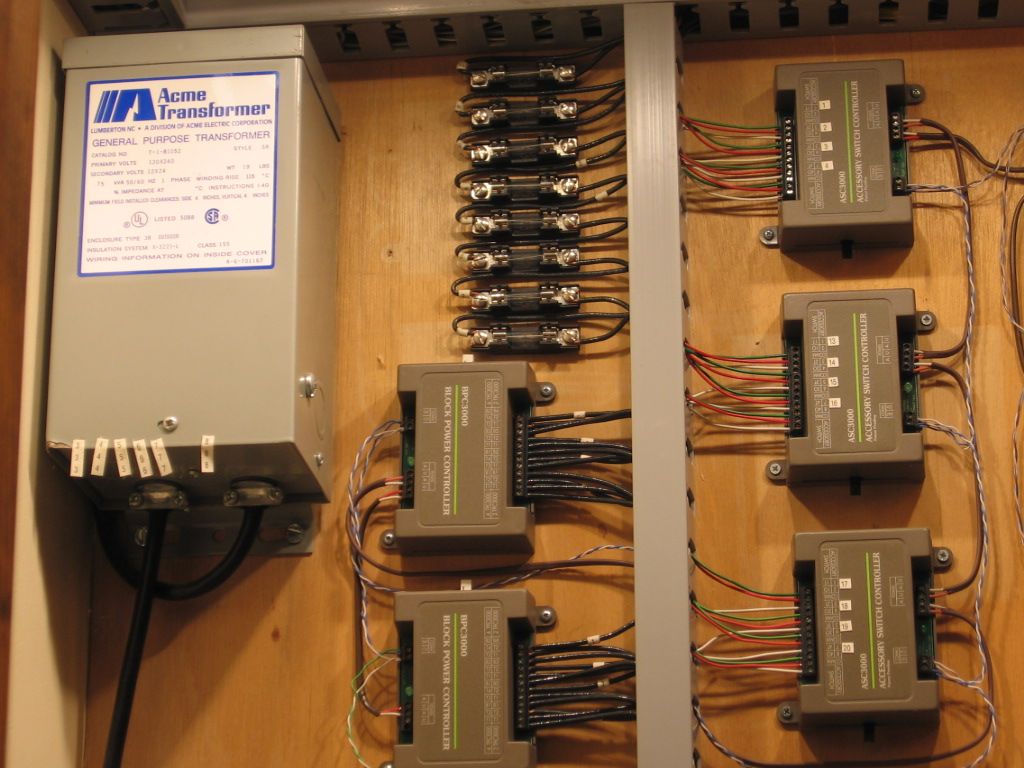

![]() For more power

For more power![]() PH 135's or PH180 can be paralleled as a power source using a Lionel plug-in adapter.

PH 135's or PH180 can be paralleled as a power source using a Lionel plug-in adapter.

These two PH180's, picture center, are paralleled to the TPC400 right, silver box, in this picture. Note the adapter lower right. Lionel Part (6-14194) TMCC TPC Cable Set. The Fort Pitt High Railers use this as a power source for the Turntable, Roundhouse modules.

Ah yes, brings back memories.

I worked at the the S-B Power Tool Company, formerly Skil, and presently Robert Bosch Power Tool Company.

The president called a group of people from most of the departments of the company. His complaint was customers have orders for bits for the Dremel brand rotary tool, and the orders are not being fulfilled in a timely fashion. He further pointed out that the markup on the bits is higher, and at one time our company had an almost 100% market share, and now that has changed. His last point was that he did not want to hear reasons why we could not, especially when we could supply bits in the past. And of course the underlying message of, if you are found to be the road block, you may be looking for a new job. Sir, message understood, loud and clear, sir. And all the supporting logic behind it.

I have bought from Hammond transformer company, I have never seen a defective product, they make fine transformers, inductors, and three-phase balancing transformers. But the Lionel unit is designed for use in the house and I assume has UL approval, and has a circuit breaker built into it. If you do go the Hammond route, may I suggest you install a circuit breaker, and then test it with various types of shorts to see if it performs as you think it should.

put some 10 Amp breakers between the ZW transformers and the TIU on every Red Channel, you will have the power you need.

Actually, that is not adequate protection for a postwar ZW, since up to 40 amps could be flowing without a breaker opening/fuse popping. In addition to these breakers, adequate protection requires a 10-amp breaker through which all the U terminals are connected.

Shamefacedly, I admit that I do not have U breakers installed at this time, but have only 5-amp breakers on the ABCD outputs.

I am pondering replacing my 65-years old ZWs with a couple of 180-watt Powerhouses, each feeding 2 TIU inputs.

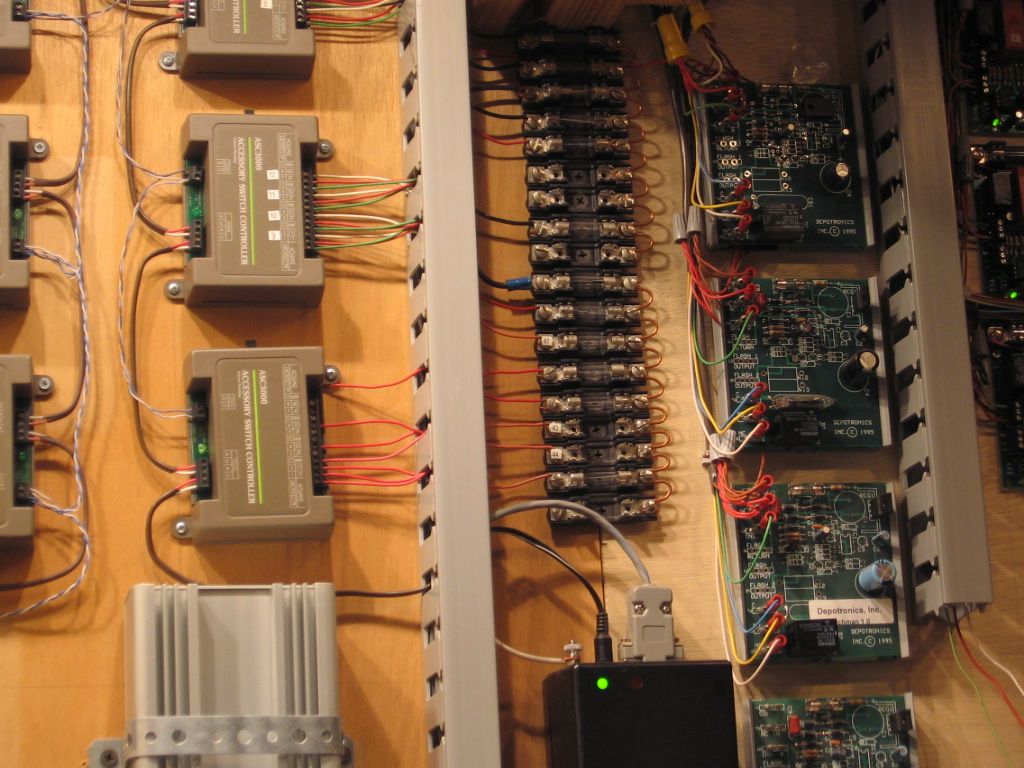

Note the fuses. Parallel PH 135 on my home layout. I fuse the (8) track circuits at 7.5 amps each. There is also an assembly for accessory fuses.

Track circuit fuses. Upper center of picture.

Accessory fuses. Center right in picture.

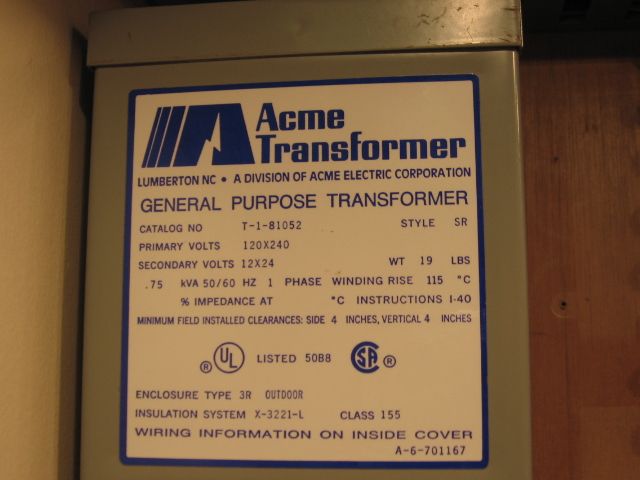

The Acme transformer (Commercial grade transformer, used for buck/boost applications), upper left, is for 12 volt accessory power, it can also be wired for 24 volts. .75KW 750 watts is pretty intense for model railroading. Most accessory fuses are 3 amps or less.

Fuse blocks are a Bussman product available from Grainger Supply

Fuses can be purchased at any automotive supply store.

Sounds like we are in the same boat. I am sold on the PH-180's as well and have also had excellent results with them, great power source for our modern electronic trains. I will more than likely just wait for the new PH-180's and get a couple when they become available. I don't have the expansion plans finished anyway, it is just a home layout and I am not in any real hurry.

Another option for you might be to try posting in the 'Wanted to Buy' forum for another PH-180? They do come up for sale around here every once in a while.

@Mike CT

.75KW 750 watts is pretty intense for model railroading. Most accessory fuses are 3 amps or less.

My comments below are for those less familiar with such devices than yourself.

I'd like to point out to the average modeler that the short circuit current of the pictured Acme buck/boost transformer is probably about 1050 amps. That compares with about 162 amps short-circuit amps from the two 135w PH transformers into the combining controller. [This could be about 231 amps if the permitted two 180w PH were used; that figure includes the permitted 5% overvoltage on the house service (ie 126v).]

The line on the Acme transformer nameplate that catches my eye is "UL listed 5088". This listing is for control transformers, the regulation of which is required to be 5% only. This means the short-circuit current is about 1/.05 or nominally 20 times the rated output of 62.5 amps (21 times allowing for 5% input overvoltage).

So the comparison is not as simple as comparing 360w (or 270w) that we might be dealing with on a large layout, but those wattages at 9% regulation, or about 11 times rated output (11.5 times allowing for 5% input overvoltage. [I had measured 77 amps short-circuit current on the 135w PH, based on 7 amps output.]

Most automotive fuses will be able to interrupt a current of 1000 amps DC (ie, the car battery into a short), which usually means the AC rating will be higher still. But if exhibiting a modular layout in a public place, you might want to use a fuse for which the AC rating is published. But your real concern is your wiring leading to and from these fuses.

You'll want to have a published set of curves (amps vs time to interrupt, plus add for fuses the clearing time of the arc) for each size of fuse used, in the set. As for time, generally there is a tolerance, not always shown. If not, find a manufacturer who does show it. From this you'll want to calculate the withstand duty of the wiring you use. The formula is:

I^2 x t = required withstand, where I=amps and t=time in seconds, high tolerance.

Commonly called the "Eye-squared tee" parameter; wire manufacturers catalogs are the best source of information on this, although not all provide it without a special request. But some do. Anyway, this is the first thing you want to check, not the last. The effort will be at least educational ![]() .

.

Remember that where information is not available, one might feel the manufacturer wants his salesmen and dealers to sell his fuses, not engineers to specify them. But maybe the manufacturer is just trying to weed out those who don't known what information to ask for.

Another problem that may arise is that the inrush magnetizing current of this Acme transformer may be several times its normal running input current, for the first cycle after it is plugged in. I believe this is 11 times normal, IIRC, but this is in its spec sheet. In design, we usually figured 12 times. We also figured in one start out of 12 (24?) this would be at a maximum. Think of the hands of a clock at 6 o'clock. One up to a plus max, one down to minus max. At 12 we may have the iron core left in max plus field on disconnect; at 6 we may have the field the start current is trying to establish at the instant of subsequent reconnection, but is unable to do so because of the residual field. Not every time, just randomly. With the newer breakers with more effective overcurrent limiting, this effect may cause nuisance tripping.

In any case, a discussion can be found on the Acme website, using the search phrase "Acme transformer T-1-81052 spec sheet" without the quotes. Drill down to a 16-page White Paper, which covers the points above and much else.

Caution: This Acme transformer has eight terminals, all of which may be wired in a particular manner. Any confusion in their use may result in an extremely dangerous output voltage. I can only comment that IMHO the input line cord of this transformer, and the output pigtails, be wired to these terminals by a qualified electrician (ie, either a master electrician, or a journeyman working under his supervision), and the case lid be secured with tamper-proof screws, or be otherwise made inaccessible to anyone other than the qualified person.

Further, the two low voltage coils should be wired as separate outputs to halve the available short circuit current at 12 volts. It should be wired as an isolation transformer, and this need in the toy train use together with the need for proper phasing in relation to a designated common (common with other transformers on the layout such that the touch voltage between any two conductors does not exceed 30 volts) should be well understood.

In my opinion: This size and type of transformer may be appropriate for a club layout which has a qualified electrician among its members. I would discourage the use of such devices in layouts in private homes. This is due both to possible unanticipated insurance complications and possible lack of qualified and knowledgeable installation, given the risk.

Often when such devices, usually rather expensive, become available at bargain prices, it may be because they cannot meet changed NEC (ie, code) or UL requirements, with a lot unsold. I cannot say if this is the case here, but it is always a concern whenever there is any public involvement.

--Frank

Thank you, Frank. Very interesting.![]()

Mike CT

A couple of notes:

(1.) The transformer pictured has a primary purpose used with one or two other transformers of the same size and electrical specifications to either Buck (reduce) or Boost (increase) voltage. Wiring diagrams for these applications are a bit unusual, (IMO) but they do work and usually pretty well.

(2.) A quiet type transformer, no 60 cycle noise, There is a feature called isolation shielded which I believe relates to electronics applications.

(3.) Frank mentioned screw terminals. There are wiring leads, bottom of the transformer, each is well marked either (INPUT Lines) H1, H2, H3, H4 and (OUTPUT Lines) X1, X2, X3, X4 Inside the wiring box cover is Drawing A22498. You have two choices for INPUT voltage, 120 or 240, and two choices for OUTPUT voltage 12 volts, as wired, and 24 volts. both common control voltages. IMO, they are available but, hard to find, the 18 volt transformers that would match well with model railroad voltages. IMO.

(4.) There are actually (Four transformer coils in this box) (Two H, or high voltage coils and Two X, or low voltage coils. Coils wired in series accommodate the high voltage, coils wired in parallel the low voltage.

(5.) House line voltage, as wired: One wire of the 120 volts feed is applied to H1/H3 wired together, and the other wire of the 120 volt feed is applied H2/H4 wired together. Parallel coil wiring.

(6.) Accessory Low voltage as wired: 12 volts One wire of the output is hooked to X1/X3 wired together and the other wire is hooked X2/X4 wired together. Again Parallel coil wiring. Other wiring applies to 240 volts input and 24 volts output Diagrams are available inside the wiring box cover.

(7.) There are shield and ground wiring in addition to the coil wiring.

(8.) Another point that has not been mentioned. The neutral or zero volt conductor of commercial transformers, on the secondary side, is connected to the ground system to assure the zero volt potential. I tried it here, but it didn't work. Worked fine for the accessory voltage, but canceled all the TMCC signal. Safe to assume that the secondary coils of the PH 135's and PH180's pictured do not have one wire grounded. Note that there is no ground conductor, three prong 120 volt cord end, on either the PH135's or PH180's, I would assume this feature is built into the UL listing for these devices. I did ground the metal shell and shield, using a three wire conductor with plug-in cord end, for the Acme transformer shown.

(9.) Somewhere in the wiring shown, track commons and accessory commons are connected between the three transformers shown, necessary for isolated track rail activated accessories. Most noted, the automatic non-de-rail feature of all the switch motors. There are also isolated rail, track activated crossing gates.

Best wishes

Mike CT

Correction to my previous post:

The search phrase I mentioned for the Acme website portion for the Acme transformer drills down to a 4pp set of connection diagrams for this type of transformer, in its available sizes. To access the mentioned 16pp White Paper (explanation of how control transformers work, and two sets of equations for them--simple &quick, and second, very complete) use the following search phrase: "typical impedance of control transformer percent", without the quotes. Locate a Rockwell website entry, toward the end of the first ten results, titled "[PDF]63". This is the 16pp White Paper of interest.

@Mike-- Your description of exactly how you wired the Acme transformer was quite interesting, particularly regarding the effect on the TMCC signal [at (8)]. I did not realize this was a shielded transformer, although the mention of it being an isolation transformer may include that. I worked with these before the IEEE tried to cover such nomenclature details in this field (one book became two, and two became three over time, starting with the "orange" book). The construction probably is a rectangular core, with one high and one low coil on each of the long sides, wound one over the other to minimize leakage reactance (which would conflict with the desired low impedance.

Optionally, an aluminum shield (ie, non-magnetic but insulated) could be placed between the coils. The purpose of this shield was to prevent the capacitance between the high and low coils from transferring an electronic signal (ie, high frequency) across the inter-winding capacitance. I believe the supplied ground wire pigtail must be connected to this shield, and probably only the shield, for the shield to be effective.

The green and signal grounds were sometimes handled in very complex manner (I recall once needing a breaker sub-panel in its box to be mounted on insulators inside an outer box; I was astonished to learn that such things were already available.).

On a train layout, of course, the secondaries have the outside rail in common, but there is no premises (ie, green) ground on the common wire. This is per the UL standard for toy transformers, 697. I do not know the history of this, but it is related to the concept of avoiding the hazard associated with an extended grounded surface, which the layout tracks would otherwise be. That is, "dead-front" tracks are wanted.

As to the TMCC signal failure, the grounded (green-grounded) shield doubtless provided a very effective direct premises ground (via the capacitance between the shield and the low voltage coils) to the outer rails, preventing the command base from driving the intentionally isolated outer rails to a slight voltage above premises ground (green ground) at the TMCC frequency. [This also happened in the first Z4000/TIU interfaces with the TMCC base, using a direct-wired RS-232 link cable. It seems that the RS-232 signal ground wire is generally connected to premises green ground by electronics people... MTH had done this; while Lionel had not, but instead connected their base signal ground to common and the common outside isolated rail. Optical isolation of the signal connection solved this.]

So your disconnection of the "ground" pigtail was correct; I do not think it was either a neutral tap, or a connection to one end of the low voltage coils. It does not show in the 4-page wiring diagrams (see correction above), suggesting it is an optional addition not usually provided, which a grounded shield would be IMO.

Speaking of wiring diagrams, my suggestion of using the two coils of the low side independently is not shown. Instead, there is a note saying any way of wiring not shown should not be used. So, maybe the core will fail to magnetize properly unless the coils operate both the same. I have an Acme catalog including design comments somewhere in the cellar which may have comments on this issue. At least for now I have to withdraw the suggestion.

--Frank

![]() Thanks Frank

Thanks Frank ![]()

I enjoy reading your post(s).

Best wishes

Mike CT.

We are building a very large modular layout with 5 of what we call power districts. Each district takes 4, 180 watt power houses.

Are you paralleling four transformers for 40 amps on the track??? I guess I don't really understand exactly what you're trying to do. If you're really using that much current for one power district, I have to say I believe that's a serious mistake if they're all parallel!

gunrunner: each 180w transformer powers one tiu channel in a power district The power district is made up of two routes, Highland and Central, each route is split into a left and right sides to make four separate routes so each tiu out, is powering one of four routes, with 10 amps. Each route has at least, 80 feet of track. We have one area with yard tracks that has 187 feet of track. I want enough power on each separate route to support 3 engines and passenger cars. All passenger cars have been converted to LED's. So far we are getting signal strengths of 10's all over and have run 3 passenger trains to test the amperage, with no problems. If your confused by now I will add that each separate route is daisy chained to make one big circle, and we use only one drop per circle. This may violate one of Barry's rules about how many drops to use but it works well. The layout has 42 separate modules and is divided into 5 power districts so we will use 20 180w transformers. Using four now waiting for 16 more on order at Charlie Ro

OK, that's different. It just sounded like you were paralleling a bunch of transformers, that raised a red flag, at least for me. ![]() I think you're quite safe with 10 amps if all the passenger cars have LED's, hard to imagine three locomotives consuming 10 amps, unless they were all Vision Line Big Boys with all the smoke running, that tops out at more than four amps.

I think you're quite safe with 10 amps if all the passenger cars have LED's, hard to imagine three locomotives consuming 10 amps, unless they were all Vision Line Big Boys with all the smoke running, that tops out at more than four amps. ![]()

I think your usage of "power districts" was a little different than some. I consider a "power district" to be the track fed by one power source, hence my confusion. ![]()

80 feet of track on one TIU channel is quite conservative, I don't see that being an issue. As you say, the single feed may upset some, but as long as it works...

This (5) engine consist runs on one track circuit fused at 7.5 amps. You can do a lot with the 10 amps circuits provided by a Z 4000.

All units are powered and the caboose has lights. Click on the triangle to access a Photobucket video.

Sorry, I missed read the total quantities, I thought you were only needing one? Needing 16 is a whole different story. ![]()

I hope you haven't just pre-ordered the entire shipment that is in the works, I would still like to get a couple myself. ![]()

http://www.ebay.com/itm/Avatar...3:g:NOsAAOSwLzdWRiq0

eBay has things like this often. I built my own power supply from transformers similar to this.

You could also consider the 12 volt outdoor lighting transformers if you do not run your trains fast.

The name of the LHS would be nice.

Brent

Matt. what is the name of the hobby shop/