More good points Dale & Ralph - thank you. And all of it helps.

I don't have PW accessories on the layout. At this point in time, I have the following items (and I had to think about it):

- 2 Lionel Industrial Smokestacks (part of the Open Hearth Mill)

- 1 Lighted billboard on the front of the Blooming Mill

- A set of 2 floodlight towers in the Weirton Steel yard

- 2 DZ-1010 crossing gates w/ signals (which will be activated by an insulated rail or IR)

- A hotel building with 4 rooms activated by insulated rail

- A number of lighted buildings (as yet undetermined)

- Several traffic lights

- An industrial crane to be controlled via Accessory Motor Controller (future)

- A 15 VAC buss already powers 22 DZ-2500 switch motors, 3 DZ-1060 signals, and 2 MTH PRR signal bridges

The only items actually on the layout and functioning right now are the switch machines and signals. The smokestacks are not hooked up and everything else is in some state of planning or visioning.Also, I have no control panel. Switches are accessible via CAB-1 or toggles on the fascia, but lights are simply going to be powered by the accessory transformers at this point in time. The thinking is that eventually I will want to dim the lights automatically to simulate a day/night cycle, but I haven't gotten that far yet.

I might end up with a number of busses myself, just to avoid moving loops between PowerChief taps and accidentally frying lights or accessories. You know, assign one tap a known set of accessories and voltage load and be done with it. Maybe try to keep that buss servicing a specific area on the layout. It looks like I'm going to need to keep careful notes on interim configurations.

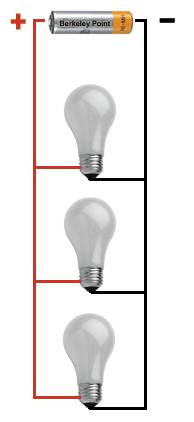

I have decided that I'm going to color code my busses differently (was planning a single Black / White one).

George