Milwaukee EP-2 bipolar assembly.

I installed the warm LED's for the head lights. Since there are two motors and separate drives, I connected the LED wires to to each separate motor and used a 2 wire connector so I can work on the engine assembly separate from the super structure.

I taped the wires and electronics to the top of the cab and also added clear plastic to all the windows. Scotch tape worked great giving a 'frosted' look to the windows since there is no interior detail.

SOMETIME'S IT PAYS TO BE LUCKY!

The engine ran great on the bench so I put the one end on the layout and it was hesitating. After about 30 minutes (or so, more 'or so') of checking for shorts, etc, and not finding the problem, I put the other EP-2 on the track and it did the same thing.

Luck #1: found out it was one of the cabeese on the cabeese track that was causing the problem. Those cabeese have been sitting there for years and one decided to short out!

Then I had more problems with the 2nd EP-2. One set of drive engines would not run (more time investigating): turns out to be a broken wire to the motor.

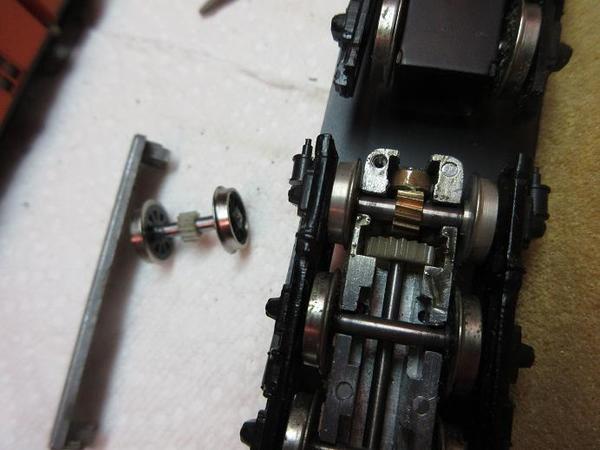

Then the other drive engine wouldn't work. Found that one of the plastic axle gears was split and, thus, slipping. Tried to CA it but didn't work.

Luck #2: I haven't had any diesels since the 70's (HO wise) but I remember some hobby town (?) wheel sets with gears in my parts cabinet. What's the chance that not only is the gear an exact match but the ends of the axles were the same small diameter for the wheels! Well, almost, the axle diameter was just a 'skoch' too narrow. The wheel was pretty firm on the axle but I could turn it. A pair of dikes worked great to put several marks along that part of the axle, causing some of the metal to be raised. That fixed that problem.

Of the 4 sets of wheels in the drive train, only the end two sets are powered. Unusual as usually, I find that all wheels are powered, giving more traction.

Back to the layout of testing and the mechanism was slipping. After spending another 30 minutes, or so, checking the drive train, turns out the front free wheeling truck wheel was binding and causing too much drag on the engine. The retaining plate was filed and bent a 'skoch' and, finally, all's working again.