I just picked up a Lionel 2333 set in fairly good condition. The back motor seems to be dragging a bit, and I was wondering what was the best way to service these horizontal motors and gears? Do the motors need to be removed to get to the brushplate and brushes, and if so how do you go about doing that? Also, is there any tricks to cleaning/lubing the gears on these types of engines? I have no problem cleaning vertical motors, but this is the first engine I have run with the horizontal motors. Whatever tips you can pass along would be appreciated.

Replies sorted oldest to newest

Olsen's Toy Trains has the Service Doc for this loco at: http://pictures.olsenstoy.com/2333.htm

Removing the two screws visible on top of the motor housing allows them to be lifted off the truck assemblies. This allows the screws holding the truck covers in place to be removed, giving access to the lower drive shaft and worm wheels.

The dummy coupler mounting brack on the rear truck does not allow complete removal of the drive shaft. It's highly recommended to replace the 22ga wire between the P/U and e-unit with 20ga wire. You can also get the bits and pieces for the P/U assembly, and associated insulators, from Olsen's to add a second P/U to the rear truck.

I did some work on a set of these, and found that if you restake the field rivets on the motors they seem to run better. Mine were loose on the slow motor.

Normal cleaning and relubrication is always a good thing to do as well.

Make very sure that the bearing blocks that hold the ends of the worm shaft go back in the way they came out: if you get them back in upside down you will have problems (ask me how I know). The ball bearing is slightly closer to one end of the block than to the other; IIRC, the "shorter" end should go into the bottom of the hole--but check when disassembling to be sure.

A few things to watch for with these units-

Clean all the grease off the truck inside and the worm gear. Put them back in and roll the chassis back and forth. If you see the worm gear shaft moving back and forth you need to shim it so it doesn't. As Len said, the rear truck worm gear shaft will not come out without removing the coupler brackets. I drill out the rivets on the end and remove it all and do the service. I then use 4/40 screws and lock nuts to replace the coupler brackets.

Watch for the wheels rubbing the trucks on these as the factory bearings wear out quickly.

A good replacement for the pickup rollers with these are the ones from the 2023 alco's. Use the whole pickup/roller assy. If you keep the original rollers make SURE you oil the ends of them.

Some people shoot grease into the "lube" holes on top of the motor shaft housings. I prefer to use oil.

Rob

quote:Some people shoot grease into the "lube" holes on top of the motor shaft housings. I prefer to use oil.

I am probably in the minority here. I avoid using the lube holes at all. I just oil the bushing directly.

In my experience, oil loaded into the lube hole will just seep past the bearings and make a mess. Grease loaded into the lube hole is too thick to work its way between the bearing and the axle.

This goes for any of the Lionel motors with lube holes.

The oil will seep past and make a mess.

I've found that injecting Lucas Red 'N' Tacky #2 under pressure while the motor is running does a superior job of lubricating both of the bushings. With the motor running at speed, inject the grease from a syringe until some just comes out both ends.

This quiets the motors down considerably, and they don't need lubrication again for several years with moderate use.

My preference is ordinary motor oil. It lasts forever. Do not use lithium grease, 3 in 1 oil, Lionel Lube, light machine oil, WD-40, etc. as these all dry out and become gummy or hard.

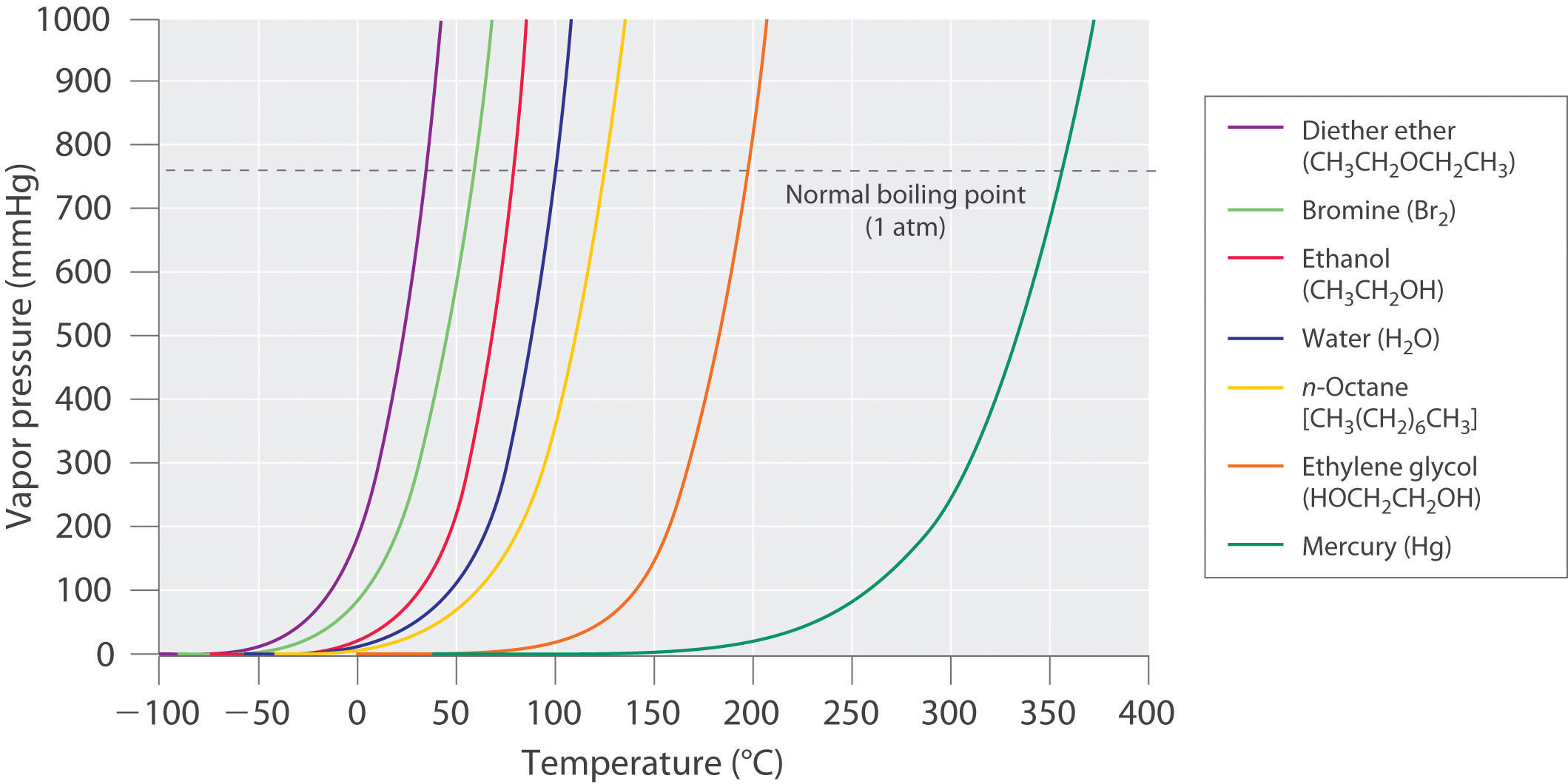

Recently, I did some research on the web to see if I could obtain the vapor pressure for lubricants. The only data I could find was for motor oil and lubriplate.

Motor oil has a vapor pressure <0.01 mm Hg (mercury) at 212 F. By comparison, water has a vapor pressure of 760 mm Hg at 212 F. What this means is that water will evaporate 76000 times faster than motor oil at 212 F. The vapor pressure is lower at room temperature.

The data I found for Lubriplate gave a vapor pressure more than 100 times higher than motor oil. This is why it dries out and becomes hard. So my recommendation is don't use it.

I couldn't find any data for Red and Tacky or LaBelle products, so I can't recommend them. There is an MSDS for Red and Tacky, but it doesn't have vapor pressure information. If anyone wants to contact the manufacturer of their favorite product and post the vapor pressure information, it would be helpful.

I couldn't find any data for Red and Tacky or LaBelle products, so I can't recommend them. There is an MSDS for Red and Tacky, but it doesn't have vapor pressure information. If anyone wants to contact the manufacturer of their favorite product and post the vapor pressure information, it would be helpful.

Lucas Red 'N' Tacky #2 doesn't evaporate as fast as motor oil.

How do you know that? What test data do you have? I had a 2025 loco in the closet for 40+ years, and the oil did not dry out. It was Valvolene 20W-40.

I'm not disagreeing with you on the motor oil.

Vapor Pressure: < 0.1 mmHg @ 68 F

Do we run our trains at 212 F?

I guess I can appreciate the vapor pressure @ 212 F being significant in a hot car/truck engine.

Why is it significant at room temperature?

Vapor Pressure?? ![]()

I use "Crisco" in my Flux Capacitor.. Never had a problem yet!! ![]()

Something so simple always turns so technical ![]() The engine has been around 60 years already, I don't think it will make a difference whether it's Red n Tacky or Motor Oil for the next 60 years!

The engine has been around 60 years already, I don't think it will make a difference whether it's Red n Tacky or Motor Oil for the next 60 years!

The vapor pressure increases as the temperature goes up. If the vapor pressure is <0.01 mm Hg at 212 F, it is much less at room temperature. I have not found any curves that show how it varies with temperature. If I find some curves, I will post them. Here are some vapor pressure curves. Unfortunately, they are not for motor oil, but they give you an idea of how the vapor pressure varies with temperature.

Motor oil is off to the right of these curves

White lithium grease or Lubriplate or Lionel Lube will get hard relatively quickly, in a few years. WD-40 gets stick very quickly. 3 in 1 oil will get sticky relatively quickly. If you don't mind disassembly your locos and cleaning a stick or hard mess out of them, go ahead and use whatever you like. I have about 100 locos, and I certainly don't want to clean them and lube them every year or two. Too much like work.