I going to be replacing the smoke unit bating in three F3. Do I put twenty drops in or do I soak the bating until it's completely saturated?

Replies sorted oldest to newest

Mr Stephen,I re do my Lionel smoke units all the time.I start out with 12 drops after I put them back together.Works every time.Nick

Good morning Nick. 12 drops would leave the batting looking pretty dry is that correct? Nick,what aside from a decrease in smoke output tells you its time to service the smoke unit. Steve

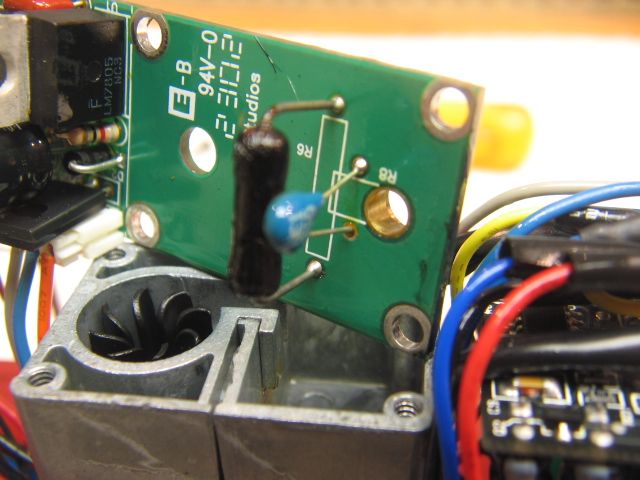

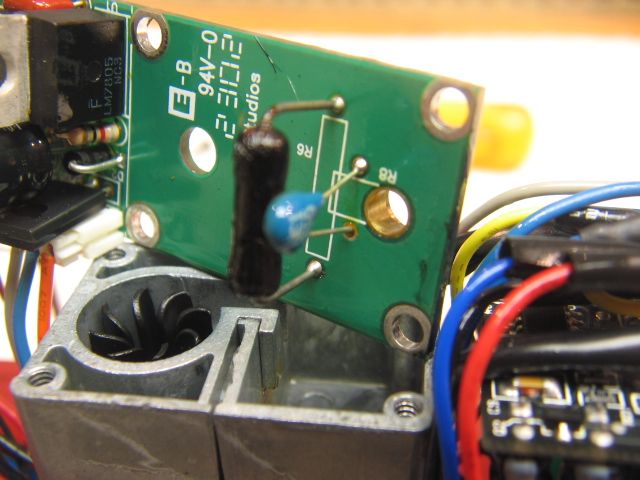

Some of the smoke units have a built-in low fluid cut-out. This Atlas TAS smoke unit has the device. There has to be enough fluid to cover the smoke resistor and the low level cut out sensor.

The blue thing.

Nick,when you open your smoke unit what do you find? Is the bating burnt around the resistor,and is it rock hard? My units were rock hard and black. Should the resistor be resting in saturated bating or would that have an negative effect on the smoke unit performence?

I've rebuilt several Legacy F3/F7 smoke units, and I would use 20 drops for a first fill, and then add 10-15 more after running for a few minutes. (7-10 minutes, or sooner if the smoke output diminishes.) Don't forget to switch the smoke unit off, and allow it to cool for a couple of minutes before filling.

After the initial filling process, and in normal use, I refill with 15-20 drops when needed.

I normally fill using the rearmost exhaust stack, as this is the closest to the smoke unit, and I also find that blowing gently down both exhausts after filling ensures that bubbles don't form to impede the smoke output.

Hi Nicole, Thank you, that sounds like a good game plan to follow. Have a wonderful day. Steve

I'll second Nicoles comments. The biggest issue with Lionels F units is the dual outlet and funnel down to the smoke unit where fluid tends to sit or get trapped.

I'll often fill F units at the end of an operating session, or the "night before" the next one to give the fluid a chance to get down into the resovior. The "gentle blowing is important.

IMO more often than not smoke units lack fluid as opposed to being overfilled. Smoke fluid only lasts maybe 10 minutes at best before needing to add again.

Any time I opened a troublesome smoke unit thinking there should have been plenty of fluid in there, it was bone dry.

Lastly, its been my "impression", that new wicking needs to get "seasoned" so to speak before it readily absorbs fluid. Kind of like a new sponge or automotive chamois.

The fluid tends to sit on top of new wicking, until it gets a few uses. This is why some locos "spit" fluid droplets out of the stack.

Some of the smoke units have a built-in low fluid cut-out. This Atlas TAS smoke unit has the device. There has to be enough fluid to cover the smoke resistor and the low level cut out sensor.

The blue thing.

Mike, That is not really a low fluid sensor. It is a thermistor that measures temperature. When the smoke unit fluid is diminished the temp of the element will rise since there is no evaporation to help transfer heat. At a certain temp the electronics turn off the power to the element. G

When I rebuild a smoke unit, I soak the wick pretty thoroughly with it still open and then bolt the top back on. It takes a lot more than 12 drops to prime a dry unit for any that I've ever done.

Good to know info, thanks to everyone!

One other running tip I do is after running smoke for a while I shut the smoke unit off to cool down for about five minutes before I'm going to power down for the night. As Nicole said I add 15 to 20 drops if needed and blow down the stack. Generally I won't run my trains again until the following night giving the fluid plenty of time to get deep into the batting. You don't have to wait overnight that's how it generally works for me.

Agreed I fill the batting till it's filled with fluid .. To be honest I gonna get flamed for this but I put a lot of fluid in my units .. I never have problems Lionel's new smoke units drink the fluid .

Thank's Everyone, I will make good use of all the information I have just read. All of my questions about smoke units have been answered. Thank you all once again. Steve

Nick,when you open your smoke unit what do you find? Is the bating burnt around the resistor,and is it rock hard? My units were rock hard and black. Should the resistor be resting in saturated bating or would that have an negative effect on the smoke unit performence?

The resistor should be firmly in contact with the wick or the unit won't smoke at all. You don't want to cover it, you just want it "sleeping" in the wick material. ![]() Also, make sure there's an air passage from the fan chamber over the resistor and to the stack. If that's blocked, you won't get much, if any smoke output.

Also, make sure there's an air passage from the fan chamber over the resistor and to the stack. If that's blocked, you won't get much, if any smoke output.