Can anyone enlighten me on why some tenders have electric pick ups on the trucks and some don't ?

Thanks

|

|

Can anyone enlighten me on why some tenders have electric pick ups on the trucks and some don't ?

Thanks

Replies sorted oldest to newest

Thank you bmoran4.. that makes sense. I had a model a while back that did " not" have pickups and it would stall on switches and some other areas if I was operating at a slow speed.

So if I'm understanding you correctly, a tender with pickups would help/ possibly eliminate that problem.

Yes, adding pickups and a power tether wire to a tender can help engines navigate switches provided they stall due to the small electrical footprint. This has been documented countless times on the forum. Use the search functionality of the forum.

Thanks again bmoran4...I will continue to search through the forum.

I guess I should make sure any Locomotive I buy ( 0-6-0 , 2-8-4 or 4-8-4) has pickups on the tenders .

Most of pickups are very close on the Locomotives themselves.

I only have seen a couple 4-8-4 , where they are spaced out like a regular.

Thanks again .

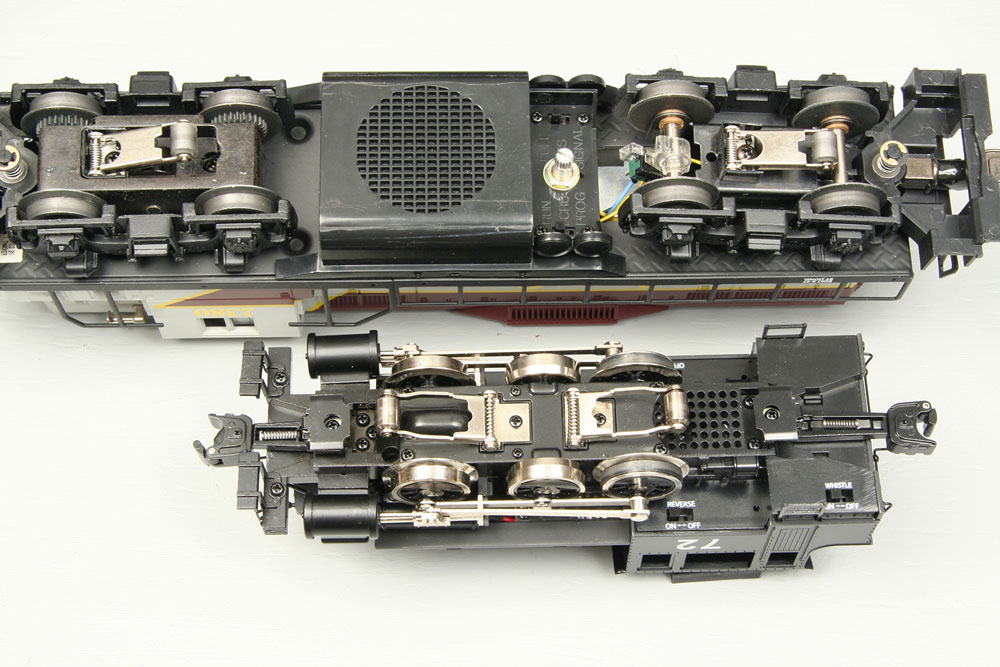

I find that most small locomotives with pickups closely spaced greatly benefit from connecting the tender pickups for power as well. AMMOF, most of the brass upgrades I do where the locomotive only has two pickups usually get a tender pickup installed as most of those don't have them from the factory.

Gunrunerjohn...so we can add pickups ourselves ! That's great. Perhaps a stretch of my talents, but possible.

I had read in the forum where electric pickups on the tenders were recommended.

Looking at the new models from Lionel, I see very few with them on the tenders. Even some Locomotives with close pickups on the motors. It seems confusing.

I was also looking at the Lionel LC 2.0 Berkshires. None of the tenders have pickups.

Thanks for sharing your knowledge.

GRJ where can I purchase the pickup and insulated plate shown in your photo?

@KKNAPPER posted:Gunrunerjohn...so we can add pickups ourselves ! That's great. Perhaps a stretch of my talents, but possible.

It's just a little mechanical work, and running a single wire from the power to the pickup. For many locomotives, the power is already in the tender for sound and/or drive electronics, if it's not, I just use a one-wire tether to bring it over.

@KKNAPPER posted:Looking at the new models from Lionel, I see very few with them on the tenders. Even some Locomotives with close pickups on the motors. It seems confusing.I was also looking at the Lionel LC 2.0 Berkshires. None of the tenders have pickups.

All of the Legacy models from Lionel have tender pickups, but most of them also have IR drawbars, so the rollers aren't actually connected to the locomotive rollers. For those I add that single wire tether I talked about.

The LC stuff is different, and they're all over the map on those.

@Windy City posted:GRJ where can I purchase the pickup and insulated plate shown in your photo?

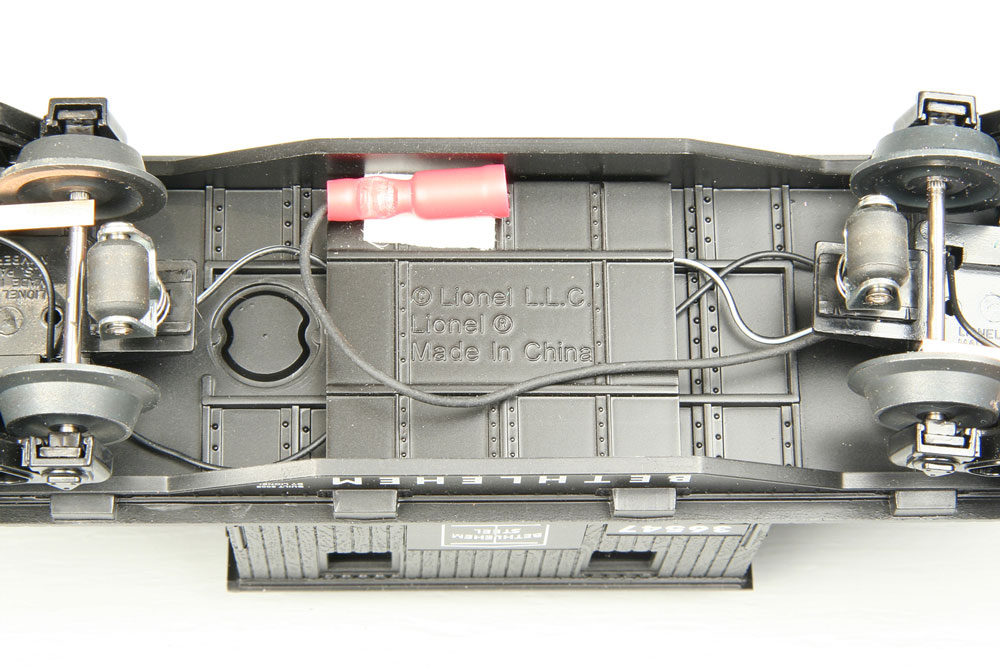

The pickup is the MTH BD-0000042, the plate I make from 1/16" fiberglass sheet.

Thanks gunrunerjohn. You answered all of my concerns/ questions.

I was wondering why some models have pickups on the tenders , however only have the IR drawbar. So the power will not get to the Locomotive. But with a tether that problem is solved !

gunrunnerjohn..I guess I should ask you know for future knowledge when I try to do this..

Is there a particular part that you prefer to use for tethers ?

*Hooking up for power from the pickup on the tender back to the power on the Locomotive.

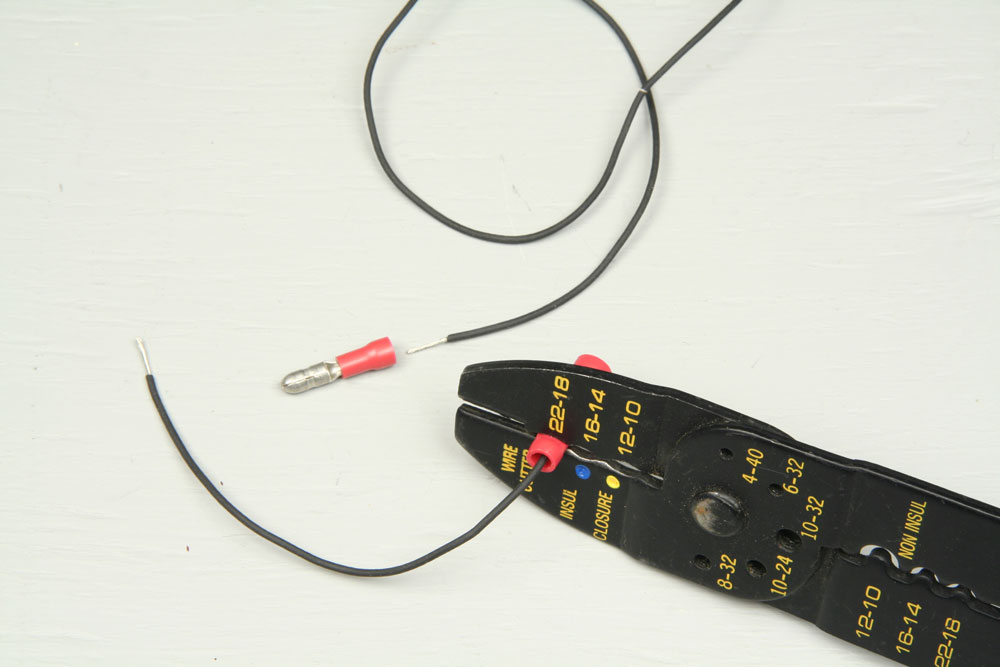

For a single wire tether, I use machine pin sockets and pins. This was an internal antenna connection, for connecting power between the locomotive and tender, I use black wire obviously.

Here's the "raw materials" for the tethers. Some wire and heatshrink and you're done.

Thanks again gunrunnerjohn.

I understand the philosophy for having pickups now, I understand the science behind them , I know what needs to be done and what parts to use.

Now I'm wondering how I do it?

I have done some research and scanned the forum.

Here is what I believe, I may have learned:

I will be soldering one end of the wire to the pickup ( or both pickups ) on the Tender.

The other end of the wire to the connection point on the motor, where the wire from pickup on the Locomotive is attached .

Connecting both wires with the mechanical pins and sockets.

This seems logical to me, but , I have my doubts on my conclusion.

I feel that after all of these requests for advice, you may request I hire you on a retainer .

I do sincerely appreciate your help.

@KKNAPPER posted:Here is what I believe, I may have learned:I will be soldering one end of the wire to the pickup ( or both pickups ) on the Tender.

The other end of the wire to the connection point on the motor, where the wire from pickup on the Locomotive is attached .

Connecting both wires with the mechanical pins and sockets.

The other end of the tether in the locomotive does NOT connect to the motor! It connects to the track pickup wire in the locomotive.

@KKNAPPER posted:Thanks again bmoran4...I will continue to search through the forum.

I guess I should make sure any Locomotive I buy ( 0-6-0 , 2-8-4 or 4-8-4) has pickups on the tenders .

Most of pickups are very close on the Locomotives themselves.

I only have seen a couple 4-8-4 , where they are spaced out like a regular.

Thanks again .

You might consider just running your new loco first for a while to see if you even have an issue that would require additional pickup rollers.

Have Fun!

Ron

By Peter H. Riddle | March 29, 2021

Stuttering through switches can be fixed with this one-night project.

(I'm adding this story I found to help anyone else who is experiencing a problem with short foot print pickups...kk)

I hope it helps.

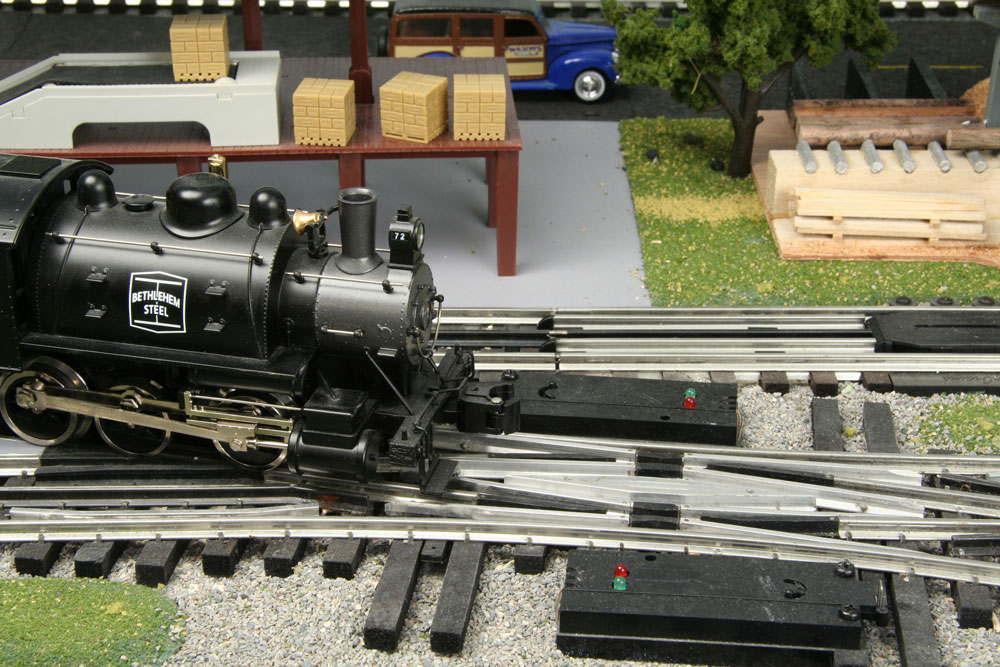

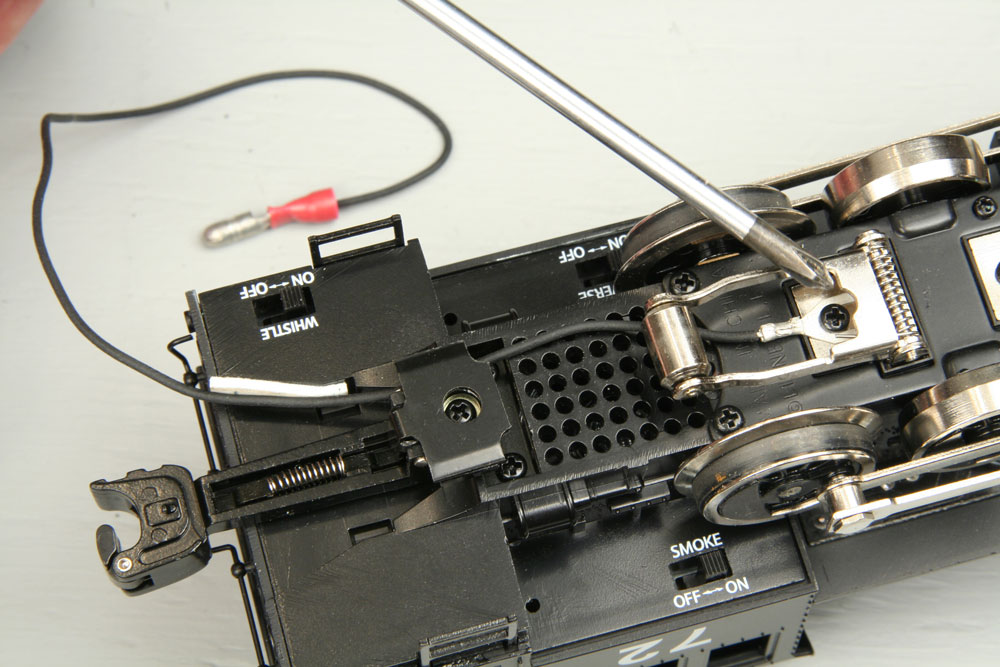

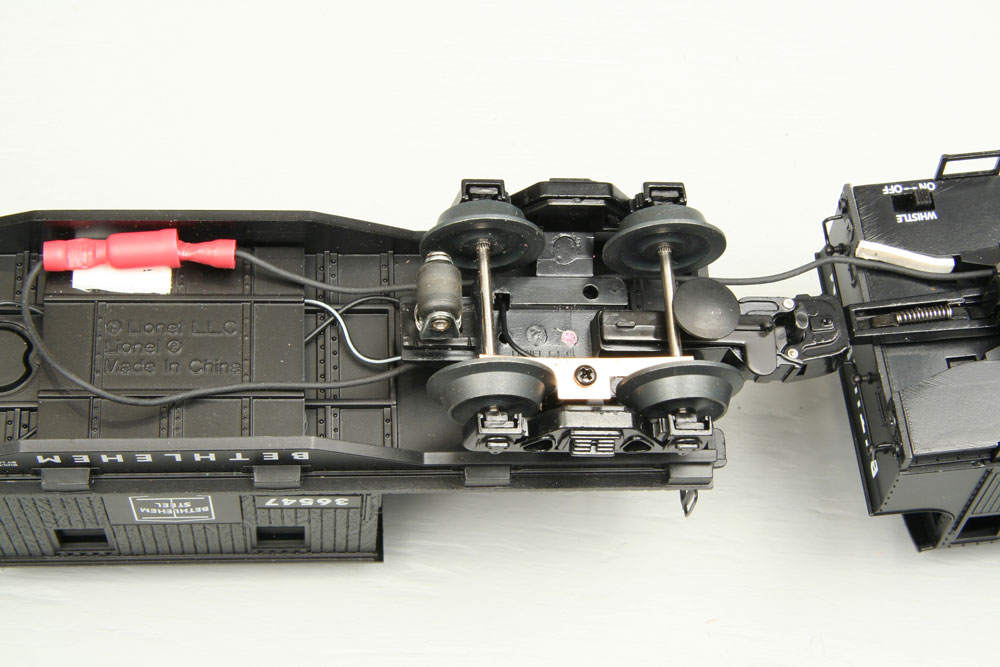

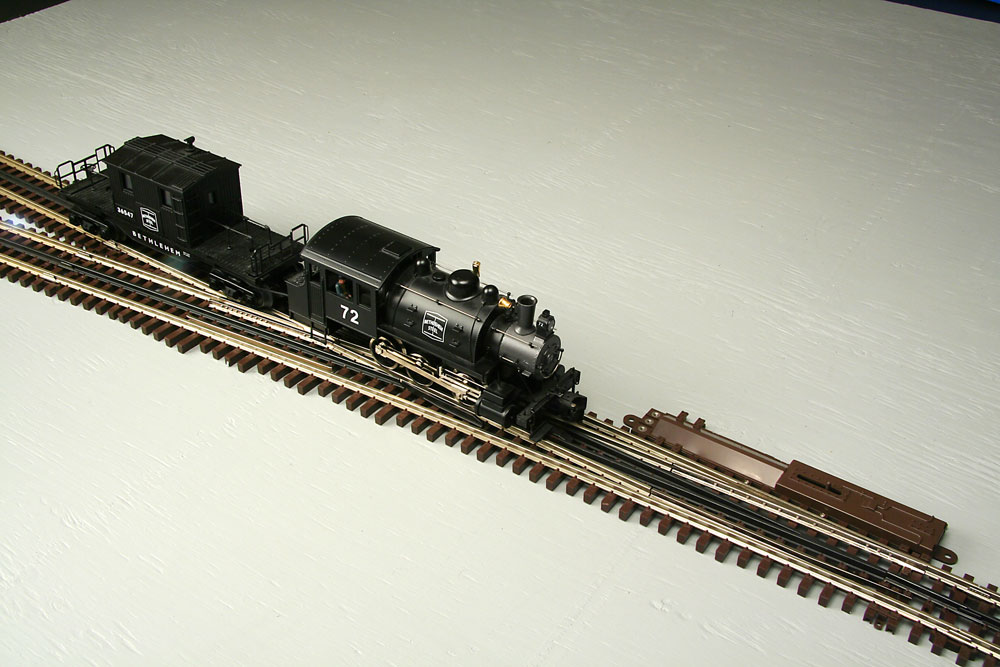

Some of today’s short-wheelbase locomotives have issues with the prototypical switches and narrow-angle crossings that make an O gauge railroad look realistic. Here’s a quick fix that will allow any locomotive - even this economical Bethlehem Steel saddle tanker from Lionel – to perform reliably over the troublesome trackwork.

The bane of O gauge operators everywhere is having a small locomotive with closely spaced power pickup rollers – operating through long switches that stop ’em dead in their tracks. Here’ a simple, step-by-step process to keep the juice flowing! Photo by Peter Riddle

22- or 24-gauge wire

Male and female solderless connectors

Crimp-on spade connector

Screwdriver

Soldering iron and solder

Two-sided tape

Wire cutter/crimper

My post war coal tenders have pickups for the whistle in the coal tender.

Charlie

Access to this requires an OGR Forum Supporting Membership