Please have patience with me and my lack of experience. I have had my Lionel O gauge Polar Express set for some years and each year it goes under the tree and has minimally expanded from the original oval to a little more track. This year I want to expand it quite a bit and go for roughly an oval shape with a few turns that will be about 20x10. I’ve read about wiring the tracks but this is going to be a temporary layout which will probably need to be broken down a few times over the period between Thanksgiving and New Years so permanent/semi-permanent wiring isn’t an option. What would those of you with experience recommend to make it work under these conditions? I’ll be using Lionel Fastrack. One option I considered is buying a bunch of these Fastrack accessory wires and connecting the exposed ends of each and then using Them with the built in connectors to periodically run between different track sections to improve the consistency of the current/signal. The advantage to those would be the ability to quickly connect and disconnect the wires to track when it needs to be broken down/put back up. Any thoughts advice is appreciated. https://www.legacystation.com/...xEAQYASABEgI2NfD_BwE

Replies sorted oldest to newest

@Mark Evans posted:"One option I considered is buying a bunch of these Fastrack accessory wires and connecting the exposed ends of each and then using Them with the built in connectors to periodically run between different track sections to improve the consistency of the current/signal.

Close. You want to run one feeder from your transformer for about every 6 track joints. I use 16 ga speaker wire (cheap) and 0.110 female spade connectors. Fastrack straights have the connectors on the bottom. Even if you end up with a half dozen feeders, they will tuck under the Fastrack pretty easily.

Another important thing, keep the track clean. I use alcohol and a soft cloth.

Yes use Lionel Trains 6-12053 Accessory Power Wire every 4-5 ft

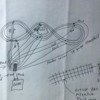

Attachments

With the layout being temporary, I have a bit of advice. Don’t take the track apart by hand. I use a utility knife to pry the track apart evenly. You will eventually spread the ends of the track doing it by hand, resulting in bad connections down the road. The feeder wires are good advice. Gilly’s method would be about a tenth of the cost over Lionel, but do what you are comfortable with.

Thank you guys so much for the advice and even diagram, it makes much more sense to me now than yesterday. Question about the terminal block, would I use the same wire to run from the CW80 to the terminal block and run all the power lines off of the terminal block?

Depends on what you mean by "same wire". If you're talking about same "size" wire or gauge, I typically run 14 gauge from the transformer to the pos and neg posts of the terminal block and then 16 gauge wire as feeders from the terminal block to the track using female spade connectors at the terminal block end and the connectors Gilly mentioned at the Fastrack end.