Originally Posted by Fred Boreale:

Rich,

How many of these staybolts are used or(needed) in a boiler?

Fred

The Baldwin 0-6-0, #26 Steamtown National Historic Site had the boiler/fire box on display for many years in different stages of repair/rebuild. At least twelve hundred stay bolts. The asymmetrical fire box requires the majority of the stay bolts.

Crown Sheet to Roof sheet 0-6-0

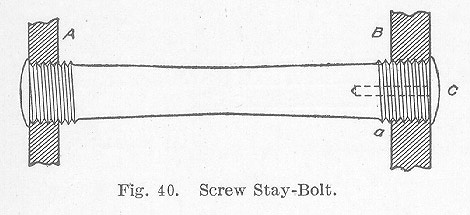

The inherent design of a round boiler usually allows for more material in the outer sheet/shell. So the expansion of more material causes lateral movement compared to a smaller inside shell. The flexible stay bolt has a ball and socket assembly outer shell that allows for the movement.

This roof sheet was part of Boston and Maine 3713 at Steamtown. Note the sockets. Stay bolts and Cap are missing.

Each time maintenance is done Stay bolts may be replaced, if broken or they leak. This requires a larger diameter bolt to be installed with new threads and machining. Eventually as the bolts become too large the sheets are replaced with new. Lots of work for lots of skilled workmen. Welding stay bolts that leaked was a quick fix. If you look closely, on old steam that is displayed, you should see some of the quick fix welding.