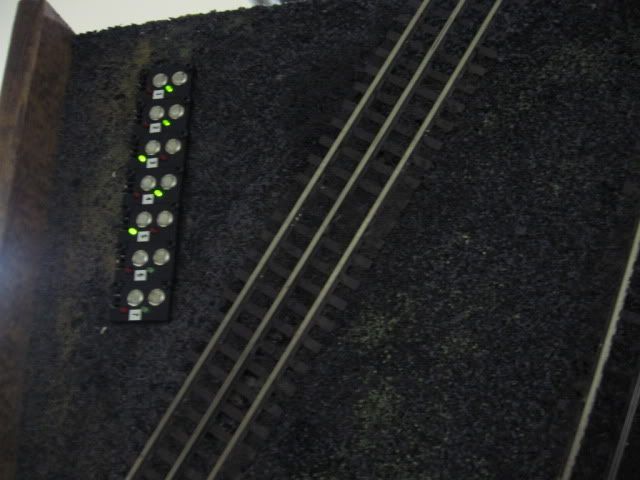

I used a Ross 3-way switch on my inside mainline to save space on my 6 X 15 layout. One leg connects to a # 4 switch coming off the outer mainline; the second leg goes to the three stub yard in my missile rail car base.

Both switch motors are connected and work fine. I found this switch needs to be operated in a "by the numbers" mode, namely, line it for the left leg, the straight leg or the right leg, allowing the points to line up properly. You're not going to be able to "slam" in one motion from one leg to the other as you could with a # 4 that just has one straight and one diverging leg.

I have not had a single derailment with this 3-way switch. (In fact, the only derailment I've had since installing the track 6 years ago is on a # 4 switch behind the chapel in the photo above. A shoe on a truck climbed over the inner rail at the switch and split the points enough that the errant truck went on the diverging route and the first truck went straight.)