How does it compare to a 40 watt iron? I'm soldering feeders to Gargraves and to12 AWG buss wire

Replies sorted oldest to newest

There was a recent thread about soldering to gargraves track. I would definitely use a bigger iron if possible. It reduces the amount of time that your iron is in contact with the rail.

I like your buss!

The Weller I usually reach for is their 260/200.

It's not just the heat range but all three ends of the tip need to be clean with clean sockets and tight screws.

Dremel touch the rail base/web and trim off exposed bare wire & cut insulation off feeder to expose fresh copper.

Flux and tin both wire and rail.

With a hot iron and a dab of solder on it's tip, just touch and get off the connection.

To help hold the wire onto the rail I drill a hole in the spike location and bend a few zig zags in the last inch or so of the feeder so it will not fall to the floor, bend a "spike head" on the feeder end, flux both and solder.

If the connection is not made in the first couple of heart beats go back to top of post.

Other's mileage may vary.

I use my Weller 100/140 gun for track work, it has plenty of heat to do the job. 40W is likely not sufficient, and 80W is probably OK, but marginal.

Agree with John above …I used my pistol grip Weller for track work, but took it one step further, I cut open the leads, thus basically turning my gun into a portable resistance soldering gun,….I used Atlas track, so making the rail joiners part of the circuit completion of the soldering gun put a lot of heat in a tiny concentrated spot fast,….made short work of soldering 16 gauge feeders ….just another trick to add to the arsenal,….

Pat

Ill 3rd the above. Get the Weller 100/140! Excellent for track and all hevier soldering tasks. ![]()

Rod

Having never soldered before I've been practicing recently and plan to solder wires to my track this weekend. I've already buffed the areas on the tracks to hold the solder joint with my dremel and tinned the wires so I'm ready to go.

The point of this post is that if Gunrunner makes a product suggestion it's spot on. When deciding on what to buy I simply bought what he uses and it's been smooth sailing so far! ![]()

-Greg

In that case Greg, look for a used Weller 100/140, the kind with the nuts to hold the tips. The newer model with the setscrews is much more troublesome.

Original Weller 100/140 Soldering Gun with Tip Nuts (good)

New Weller 100/140 Soldering Gun with Tip Set Screws (not so good)

gunrunnerjohn is right, they don't make the new ones like the old ones. I had an old one that lasted 45 years. I got one of the newer ones 100/140 watt orange Weller Model 9400 with the set screws and Weller 7135w tips that burn the tips out like crazy, got it last year and already have needed to replace the set screws and the plastic casing gets hot in your hand very quickly. Certainly not made like the old Bakelite casing but the 9400 was the only model in stock last year when I needed one. Supply chain issues (tips made in Mexico) and on the slow boat from there or sitting on ships or docks to be unloaded with no known back in stock date then. I'll definitely be looking for a good used ones and hopefully good old tips that would last forever from when they were made in the USA. Unfortunately those days seem to be gone forever.

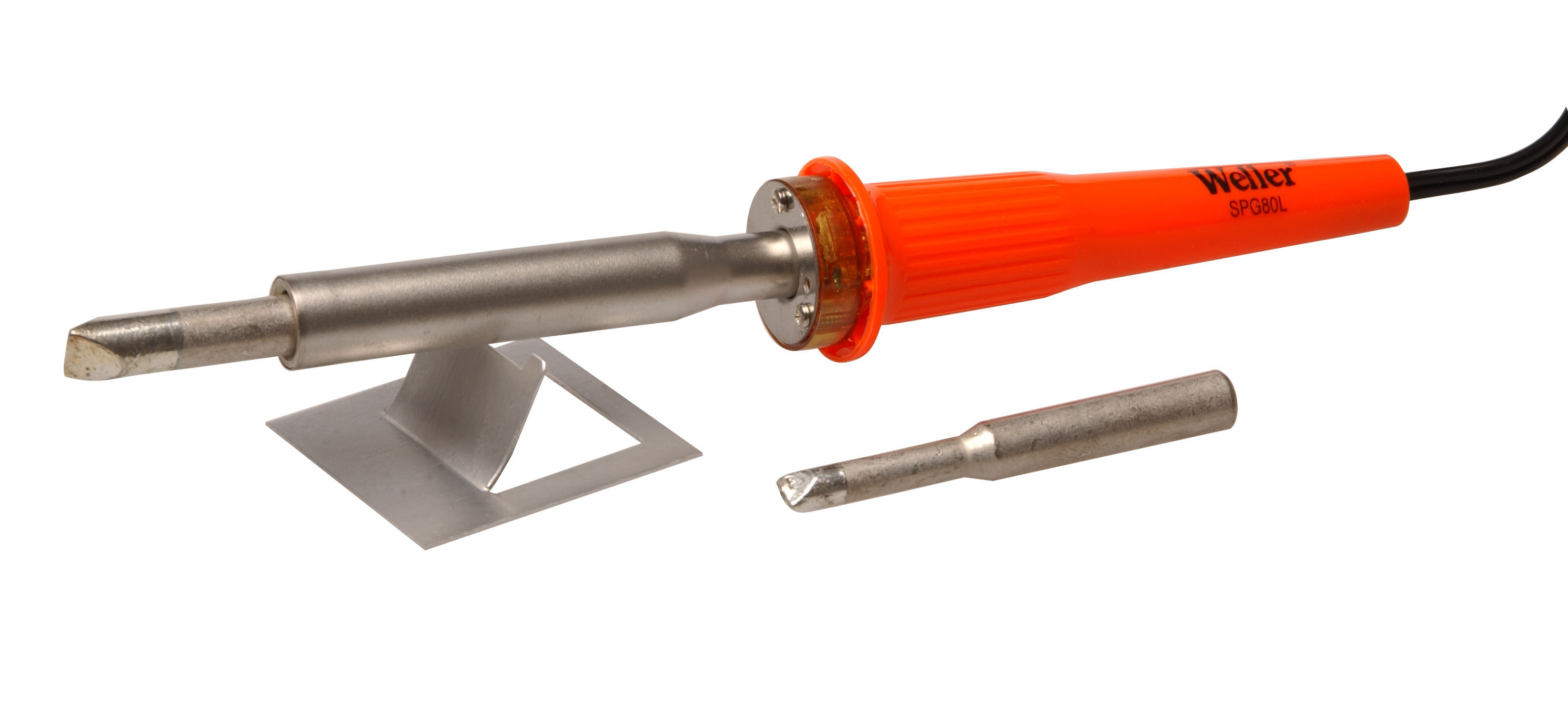

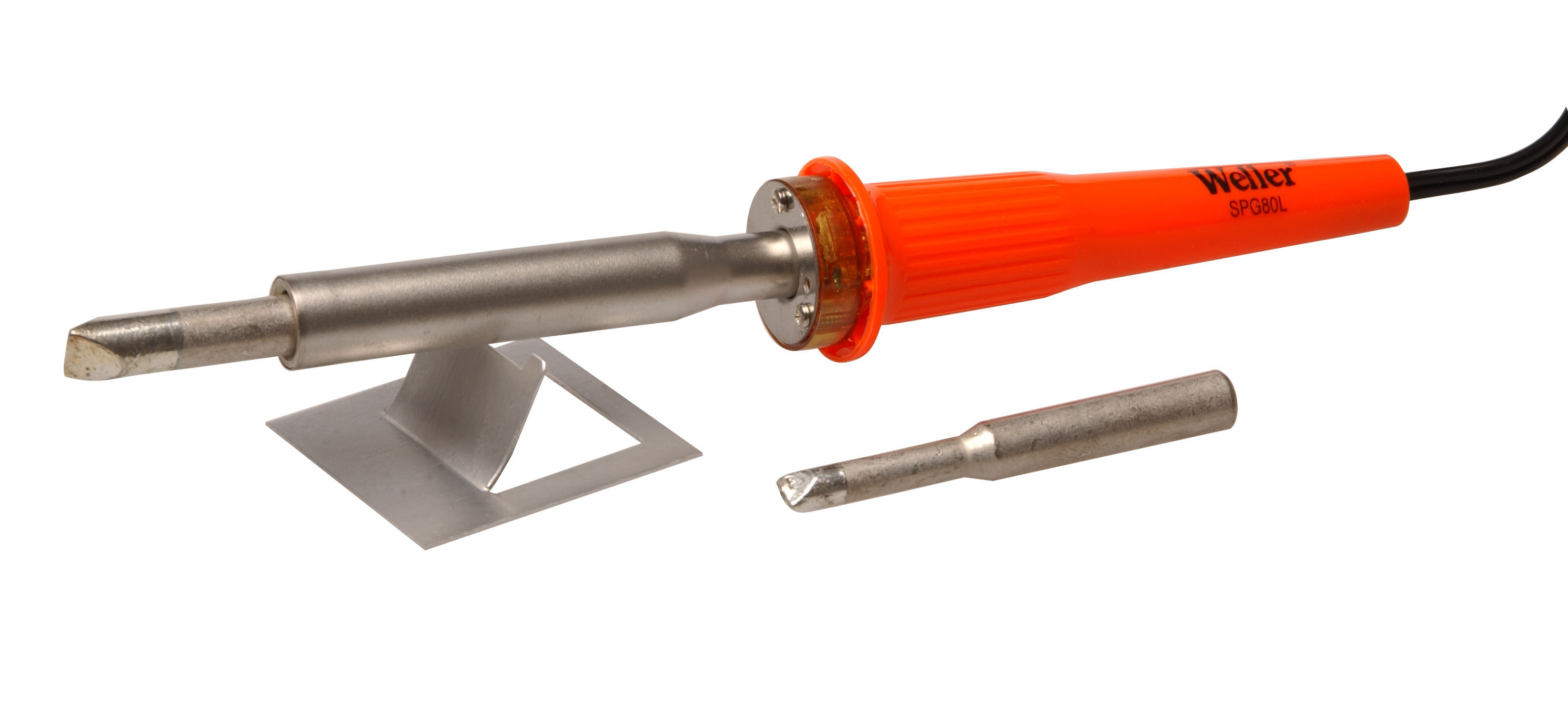

I interpreted the original question to refer to one of these.

This is more than adequate for soldering track. Its less about the watts than the thermal mass of the tip to maintain the temperature required.

Pete

14AWG copper wire works fine for the 100/140 Weller. Just bend it like the Weller tip. And I use 12AWG for the 250W Weller.

Back in the day this Weller pencil model received quite a bit of praise, probably because it's more maneuverable than a gun and just as powerful, but it's apparently no longer in production, except in a 230 VAC version in the UK:

I've been trying to find a used U.S. version (W200 I believe).

Follow this link: One Neat Old Iron | PLCProf

Thanks @PLCProf for the heads-up:

@PLCProf posted:I do have one neat old iron, for a while Weller made a W200, a 200 watt iron with the magnetic temperature controlled tips. You should see how that solders track! A delicate "Big Bruiser," so to speak.

Mike

Attachments

My wiring days under the layout are pretty much over. Recently I re did the trackage in one area. I have an assortment of Milwaukee 12v tools. I picked up their soldering iron a couple of years ago to use at work as a fleet mechanic. Works very well and I used it on my trackage re do. Easily solders Gargraves and feeders on to buss wires. Best of all your not dragging a cord around or sitting on it under the layout. If you opt for the larger battery it rests nicely on it when you set it down. The negatives are weight and battery time. I probably wouldn’t make this my only Milwaukee tool. But if you have an investment in their products and batteries already. I think it’s worthwhile.

Attachments

@Norton posted:I interpreted the original question to refer to one of these.

This is more than adequate for soldering track. Its less about the watts than the thermal mass of the tip to maintain the temperature required.

True Pete, but I find the gun more convenient and the tip reaches places where that big tip can't go. Also, the gun tip cools down very quickly, so there's no danger of cooking you or something else when the iron falls off the stand.

Since he's buying a new iron anyway, I'd personally recommend the gun over this iron. YMMV

I understand everyone has their personal preferences. My Weller gun mostly gathers dust. I have the much recommended Hakko iron too that is still new in its box. My 45 watt Ungar still does most everything asked of it including soldering Gargraves and when more energy is needed I go with my homemade resistance unit.

Pete

I'm sure you can sell the Hakko for a decent buck. ![]() As for the Unger, I'd never make it with something without good and accurate temperature control, so that one would clearly never work for me.

As for the Unger, I'd never make it with something without good and accurate temperature control, so that one would clearly never work for me.

I couldn't agree more with what @gunrunnerjohn said regarding the newer Weller 80 watt guniron. For comparison's sake, I've never used the old one, but went through my fair share of $9 to $18 soldering irons(was just starting with soldering and you get the quality for which you pay). It was better than the one's I had used previously, but it was quirky. Eventually I ordered a decent soldering iron from Amazon that's held up well and has an adjustable temp dial, also got a cheap, but "works for my needs" soldering station from Amazon. Both of those are better than the Weller gun and the iron I purchased was certainly close in price.

Attachments

@Norton posted:I interpreted the original question to refer to one of these.

This is more than adequate for soldering track. Its less about the watts than the thermal mass of the tip to maintain the temperature required.Pete

Thats a picture of the 80 watt one I believe. I have the similar 40 watt one and I also think the bigget surface ares of the wedge tip transferes the heat to the work better.

I have soldered quite a few feeders to Gargraves with my 40 watt.but a few times nothing seems to work and no it's not stainless. I'm old and this is my last layout but if something happens to my 40 watt I'm getting the 80. I'm almost done with feeders.

I did find my dads Weller 100 140 and I tried it but got cold solder joints. I'll keep at it.

@Dennis Rempel posted:I did find my dads Weller 100 140 and I tried it but got cold solder joints. I'll keep at it.

Unless the tip connections are corroded or the gun is defective, I can't imagine getting cold solder joints with the gun! Use a new tip if the old one is looking bad and make sure the tip nuts are good and tight.

One advantage of the gun is the tip fits in places the wide iron won't for soldering.

Dennis, its possible the reason you are getting cold solder joints with those big irons is they have copper tips which have to be cleaned and tinned. I have used 100, 150, and even a 200 watt monster that all have unplated copper tips. If they are oxidized they transfer heat poorly. If this might be the case you could try using a file to get it back to smooth bright copper and then tin it with solder. The tip may also be getting too hot and oxidizing almost instantly. If you see it turning blue or rainbow colors its too hot.

In that case you need to plug it into a variable voltage source like a lamp dimmer.

The 80 watt Weller with its plated tips is less likely to oxidize but still may get too hot if you don’t have a way to regulate the heat.

The 200 watt Weller with the magnetic tips would have been an ideal solution as they do regulate the heat. Too bad they are no longer made. I have seen them for sale but if the tips are NLA as well then it could be a waste of money.

Pete

This is the iron I use for soldering to track. I'm using Atlas track and since its solid it is one big heat sink but this iron works well. It's extremely important to properly prepare the materials to be soldered - tin the wire, thoroughly clean the track where the wire will be attached, and add rosin paste flux to the joint first. Keep the tip clean and use a dimmer or some other similar device to control the voltage going to the iron so the tip doesn't oxidize. Here's what my joints look like:

Ken

Attachments

Keep your tips cleaned and tinned. On recommendation by gunrunnerjohn I purchased on the A a brass coil ball and holder like steel wool to use to clean my tips after every use. They work good.