Originally Posted by 72blackbird:

I'm sure this topic has been covered before, but I just got back into the hobby again, so please bear with me. I'm looking to build a double track Pratt truss bridge. I know Atlas sells a kit for this, but it's hard to find, and costly when you find it. I'm willing to build one with a little less detail, so I can use my available funds for switches, track, signals, etc. Do Plastruct still sell structural O-scale beams? Thanks for the input.

Geno

Geno,

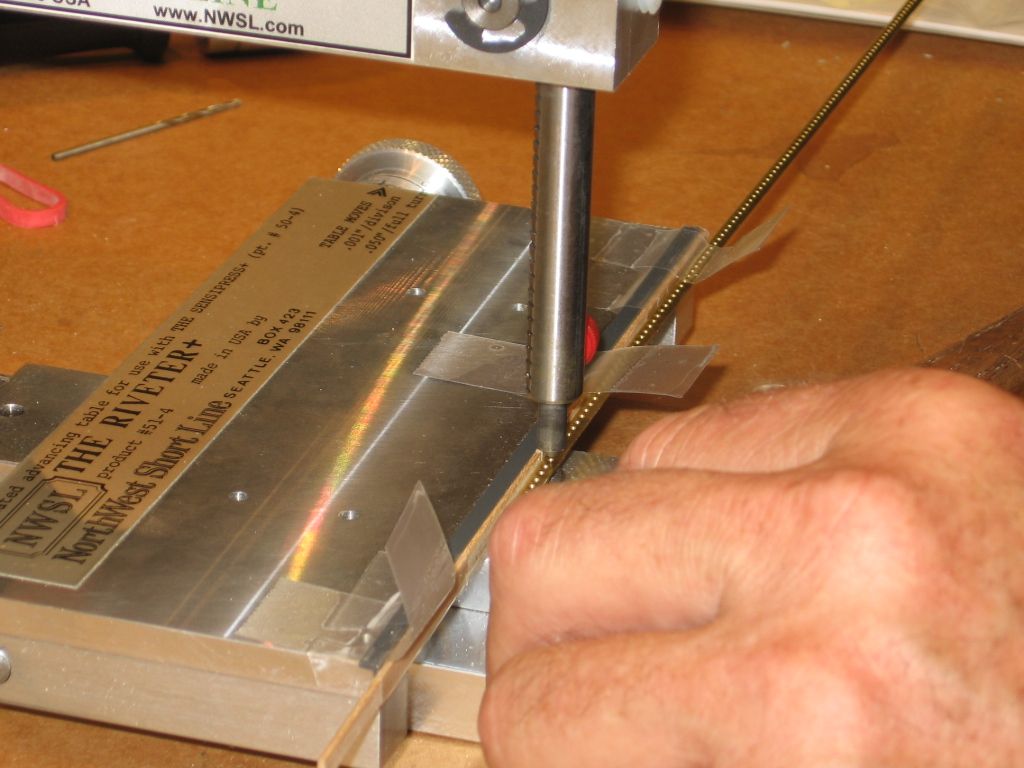

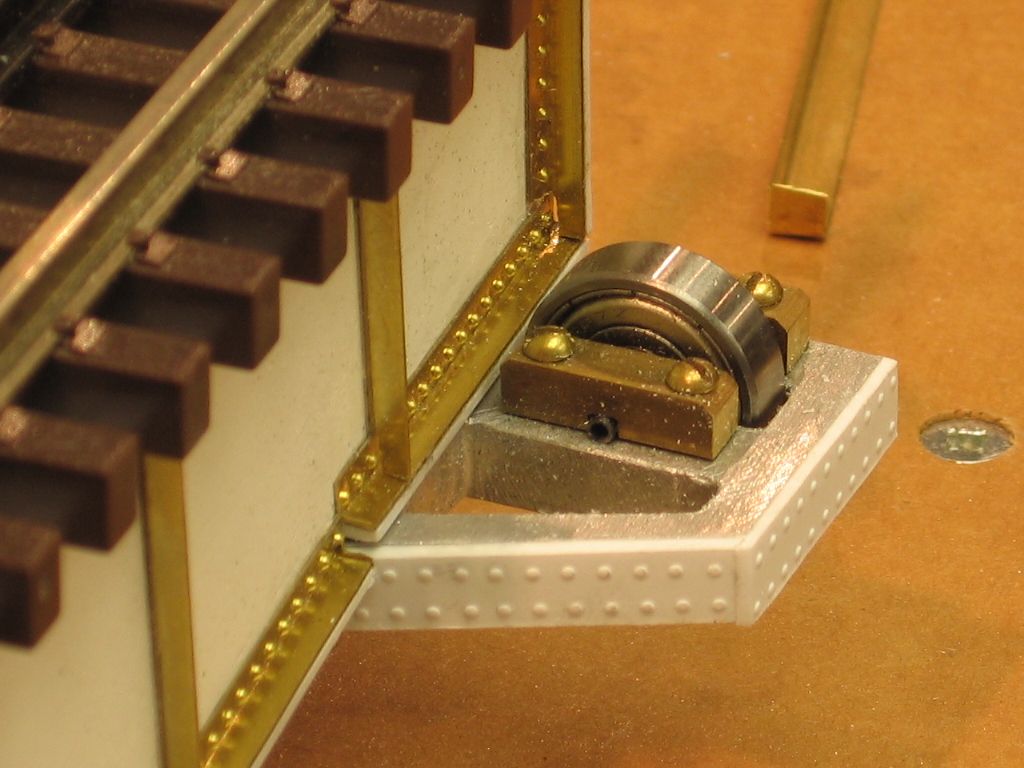

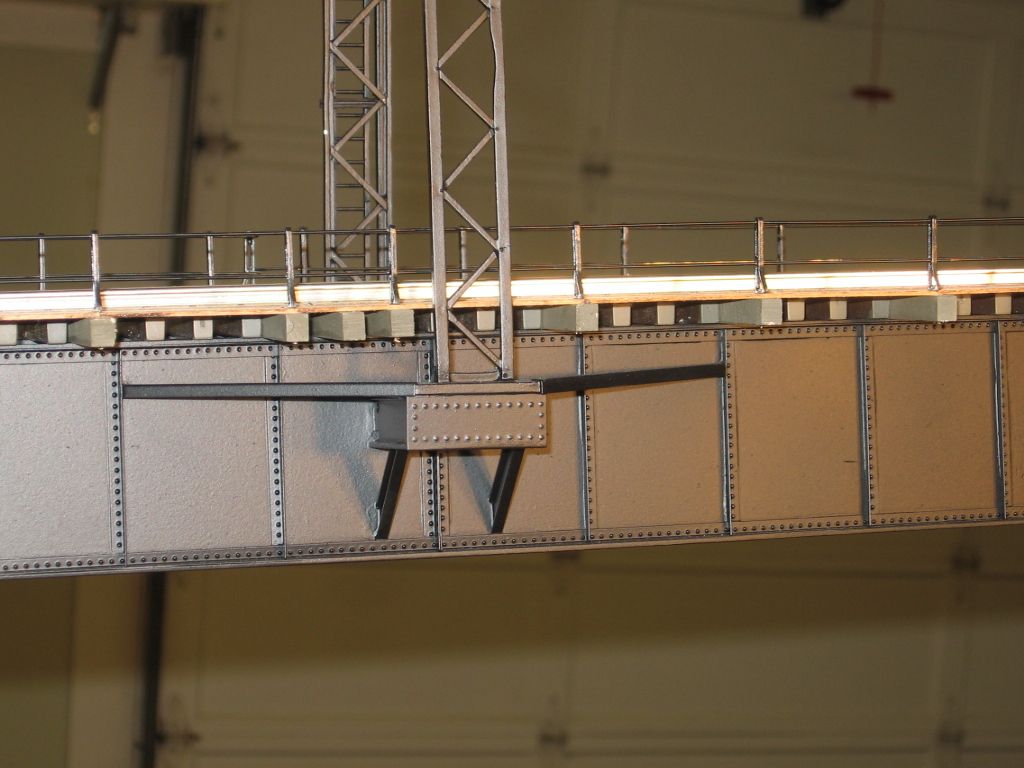

Some years back, I built a single track, O scale Pratt truss bridge using Plastruct materials and their HO plans. The plans were enlarged using a copier and Plastruct materials adjusted accordingly. It was my first scratchbuilt project and turned out very well to my eye. The only thing I could not replicate was the fine rivet detail that you'll find on the Atlas bridge.

It was 24" long and very strong. I'd like to do another, but I can't find the plans. Plans are included in Plastruct's HO kits of the Pratt truss bridge. I'm hoping to avoid buying an HO kit that I don't want for $25 just to get the plans.

I'd plan on using the stringers like Atlas does and adjust the plans accordingly to accommodate them to build a much longer bridge.

Let me know if you find some plans.

Matt supplied me with a website of prototype info and I'm still looking at the site to see if there is something I'd like to build.