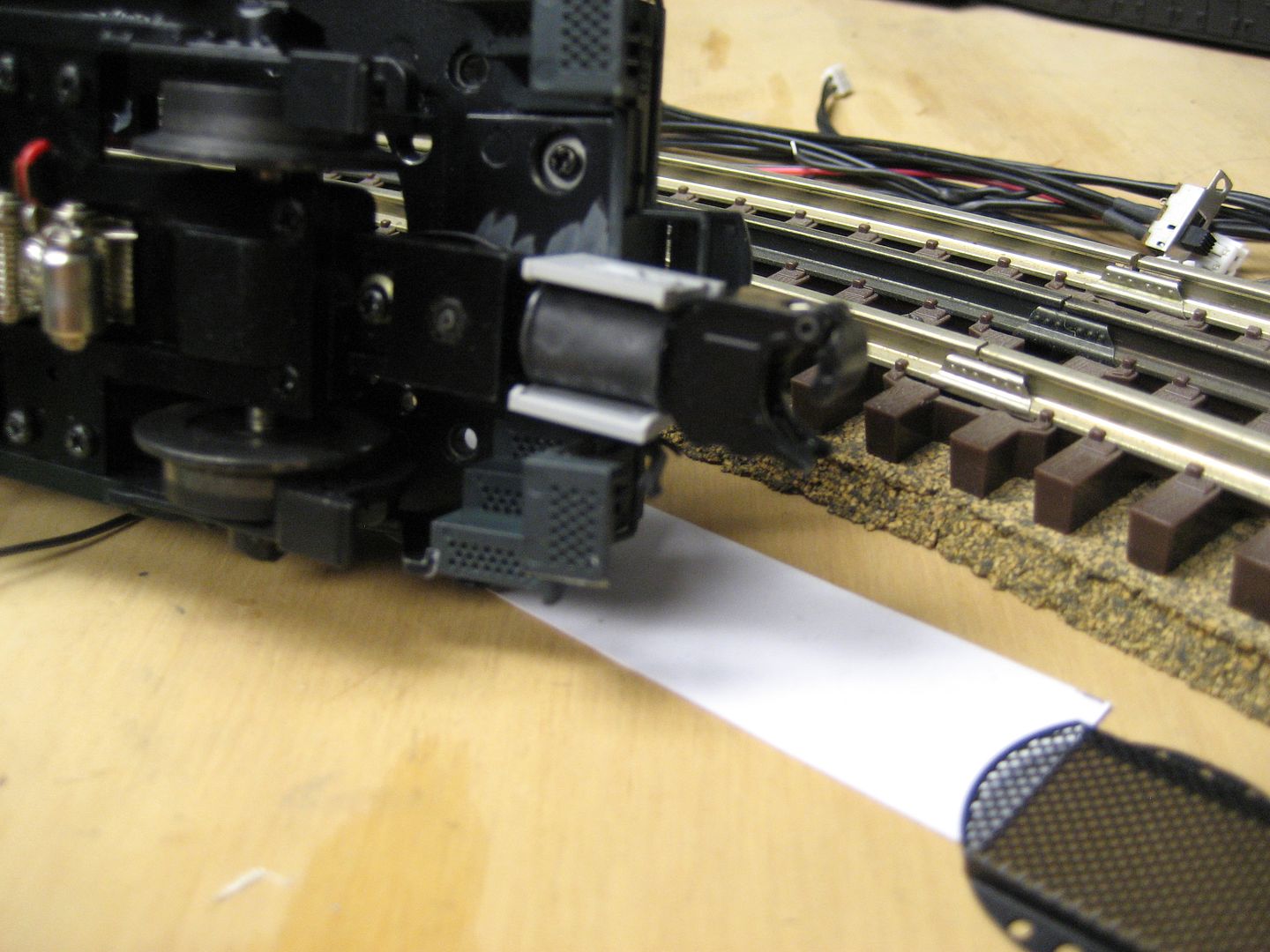

It is that time of year when my O gauge layout goes under the Christmas tree. I generally run 2 or 3 loops to have several engines going at one time. Overtime, I have had engine attrition and down to 2 loops to run a trolley and a diesel SD70 MTH Proto 3.0 engine. The SD70 has been repaired multiple times and is not reliable, mostly due to wire breakage, grounding issues, motors and LEDs. I think this engine, while spec'd for 031 is really sized and designed for 054. The trucks have to turn a lot for the 031 turns, thus places a lot of wear on the wiring. I typically run the engines for several hours a night at 7 to 10mph. My son and I have also limited the zig zag turns around furniture to limit the motion, but we still have the failures.

I think that if the SD70 dies again this season, I will just replace it with a new steamer, smaller diesel or a switcher type engine. I would think that a diesel with a 4 wheel truck or steamer with x-6-x (like a 4-6-0 or 4-6-4) would work better for reliability.

Is there any advice for which engine type is better for more heavy use on 031 that has many twists? I searched and did not find this topic, if you know of a thread, please point me there.

Thanks-Bill