Some time ago my Lionel Camelback went for a flying leap and the cow catcher broke off. Unfortunately for me the broken piece does not fit well on to where it broke off. It's hard to explain but it's like there is material missing not making the broken piece fit perfectly like a puzzle piece. I was going to JB weld it but because of the material missing I don't think it will look right. Any suggestions on how to fix something like this? Thanks in advance.

Replies sorted oldest to newest

Hi

found that lock tight black max is the best glue

it will drie fast with the excellator and is a gap filling.you can file it when it dries.

Can you Dremel off what's left to a spot where a separate detail part could be added on to replace the original? Maybe a brass part exists that can be used as a replacement.

I modified a MTH RailKing 2-8-0 boiler and in the process Dremeled thru the Bellpaire firebox I was trying to whittle down. I ended up gluing a piece of styrene on the inside and filling the outside with JB Weld, then sanding/filing it down to look like the original. That's been several years ago and it has held up so far.

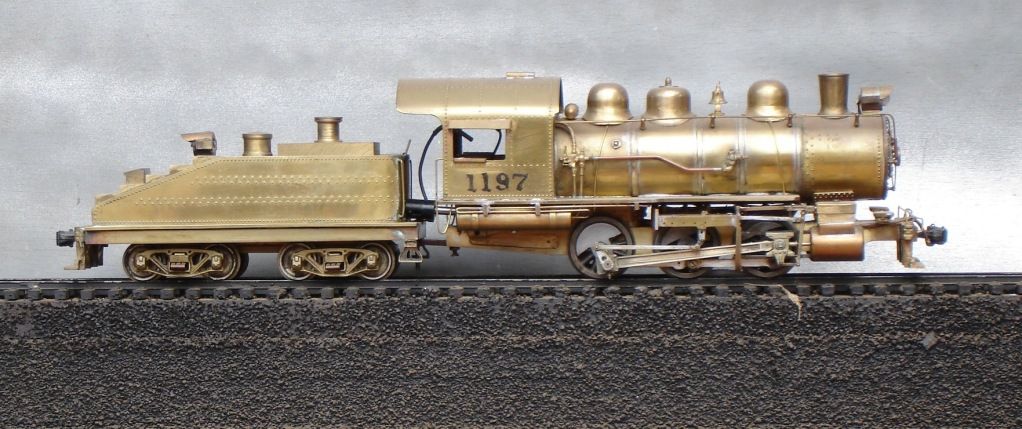

Actually, I think JB Weld is the perfect solution. I'd probably go with Harry on the Loctite 380 Black Max first for strength, then fill with JB Weld and you can sand/file to shape. I like the way that JB Weld sands and files, Black Max is pretty hard. ![]()

You know that slightly smaller Hudson die cast tender? In 1960 I sawed two of them in half to make a longer tender for my 763. I used epoxy from the dime store on the butt joint, and backed it up with card stock on the inside. Half century later it is still glued together. JB Weld is much better than the dime store epoxy I used.

My friend Harmon says he patched a tractor engine block with it. Preserved the water jacket. I use JB Kwik all the time.

Thanks a lot guys. I really appreciate it. Sounds like JB Kwik or Loctite Black Max are both pretty good ways to go. Where would I purchase these items? At an auto parts store?

JW Weld is available almost anywhere, I see it at Home Depot, Harbor Freight, and even Walmart. Loctite 380 is a bit harder to find, you may have to mail-order it. Here's one of the on-line places: Uline Loctite 380 1oz

Thanks John. Wow, the Loctite 380 is not cheap at $31 a bottle plus shipping but I guess it has to be done. I wonder how much the KB Kwik is.

JB Weld (or JB Quik) is a lot cheaper, about $4-5. It may be all you need, I keep the Loctite 380 for stuff that REALLY needs strength. I've repaired all sorts of stuff with JB Weld successfully, I just got turned on to the Loctite 380 product, so I've only used it a few times.

I keep both types of JB Weld on hand, the quick stuff is great, but the standard is a bit stronger.

Use either one but one thing I have found is that if you pin it, it will be much stronger. Drill two small holes in the frame of the engine and drill two matching holes in the cow catcher piece. Use a small piece of wire that fits tight and glue it into the holes and glue the pieces together. I have never had a piece re-break after fixing it in this way. (A piece cut from an old magazine binder wire is perfect for this).

Ed

Ed, I really like your pin idea but I fear that I won't be able to get the holes to match. I've tried to do stuff like that in the past and what inevitably happens is the drill moves slightly or thing I am using to mark the holes moves slightly then the holes don't line up. Thank you for your idea. I know I've got to get a drill press one of these days. That might help.

One way to do the pin without the critical alignment issue is to drill one of the holes a bit larger than needed, then epoxy or glue the pin in the larger hole as you put the piece together having already bonded it to the other piece.

I agree, it is very hard to align a pin on irregular pieces.

Gunnie:

Excellent idea on the pin alignment. That one has to go in the "remember this" file.

Neil

That one was discovered the same way previously described, I could never get irregular pieces to exactly line up after drilling the holes. After enlarging one of the holes, everything worked out, so that one was committed to the memory banks for future repairs. It's hard enough to align them in odd shaped pieces anyway, and it's hard to imagine a drill press helping me drill those holes in a pilot that's broken off. ![]()

Gunnerjohn, I would reword your statement: "Glue the pin into the smaller hole first and then align the parts as you place the pin in the larger hole". I had to read that twice before I realized what you meant.

That is a very good idea though!

Ed, I really like your pin idea but I fear that I won't be able to get the holes to match. I've tried to do stuff like that in the past and what inevitably happens is the drill moves slightly or thing I am using to mark the holes moves slightly then the holes don't line up. Thank you for your idea. I know I've got to get a drill press one of these days. That might help.

My advice, don't start drilling with a Dremel (or any other electric). Start with a hand held drill chuck, and a sharp or new drill. These hand chucks are almost the size of a pencil and any good hardware or model shop has them. You can continue after that with your Dremel, the drill won't walk away out of the hand drilled 'pit'. Put your Dremel at high gear and avoid too much pressure.

A drill press won't help you that much. Same thing will happen: drill 'walking' away, especially the needle sized ones. They're prone to bend or break, and they don't stand much pressure.

Kieffer

Another thing that helps is to pre-mark the spot for a hole with a center punch. The regular kind that you hit with a hammer doesn't work for a job like this cowcatcher replacement, but you can get a punch with a self-cocking internal hammer - you align the punch, press down hard, and the punch goes "BANG" and makes a dimple. The best one for this job is a jeweler's punch made by General Tool. It's about the size of a pencil and has a very sharp point. You can get it at Ace Hardware.

For work like trying to reattach the pilot, I don't see a spring-loaded center punch as much of an asset. I like the idea of the hand drill, I have several of the little hand chucks that I use with some really tiny bits for fine work. Starting with one of those is frequently my method of choice for locating a hole exactly, then I move up to power tools.

Gunnerjohn, I would reword your statement: "Glue the pin into the smaller hole first and then align the parts as you place the pin in the larger hole". I had to read that twice before I realized what you meant.

Good point, I may have to continue my English as a second language classes. ![]()

I drill holes practically every day. One of my hobbies is scratch building O Scale steamers. I simply could not live without an inexpensive drill press and the above- mentioned General center punch. Cutting fluid is also essential. I drill holes down to #77, although normally I work in the range of #43 to 63.

That does not make it the best way, but I bet if you asked folks who do this for a living, they will tell you that center- punching produces the most accurate holes. Use a magnifier, if you are over 40.

From an old OGR article.

For normal drilling, I always use a center punch. However, for something like the rough edge of a broken pilot, I'm not seeing how a center punch is all that useful. It's a skinny piece of metal with a rough surface.

Perhaps I'm just used to doing it my way, but as long as it works for me, I'll probably continue to do that. ![]()

Butter the crack surfaces with JB-Weld and prop the broken part into place. Use automotive Bondo or more JB-Weld to fill any imperfections in the joint. Finish the job by sanding and painting.

I guess I agree on spotting holes in a fracture surface with a pin vise and sharp drill. Whatever works is good.

I have one of those prewar B6 switchers, and it came with a bent cab roof overhang. One can re- bend die cast, but I do not remember being successful. Under the cab overhang is a very thin piece of fiberglas cloth, and the broken section is reproduced in JB Weld. I guess I did ok; I cannot remember which side was broken, and a casual glance does not refresh my memory.