On Lionchief steam engines the speaker is in the tender, the control board with sounds is in the engine. The tender is connected to the engine through the drawbar which also has electrical contacts.

The typical failure is either the the contacts in the drawbar connector get bent or damaged and intermittently make contact (given when the engine pushes he tender backwards, this pushes the contacts together and your sound works) and he fact when the engine pulls the tender, the only thing holding the contacts together is the plastic drawbar, if it was cracked, it could flex and thus break contact causing speaker dropouts.

Another known failure is the very thin wires that are soldered to the drawbar system have heatshrink over top that is supposed to provide strain relief from flexing and then breaking at the solder joint. This is usually another failure point and I probably repair 10-20 of these every year at the local shop. The bad news is when this breaks, if the wires touch the outer rail connection also present in this 4 pin connections, because that is AC, it blows minimally the sound amp chip on the Lionchief board or worse case destroys the entire board with AC current up DC circuits.

We need to know the exact product number of your set to ensure getting the right part since Lionel has made different versions of the Lionchief boards and some do have different connectors (before blueooth, with bluetooth, Bluetooth 5.0).

As an example a 5.0 set engine side https://www.lionelsupport.com/...RESS-5.0-ENGINE-ONLY

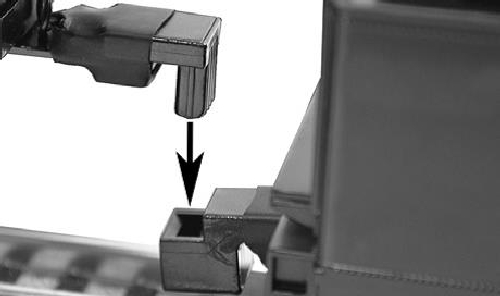

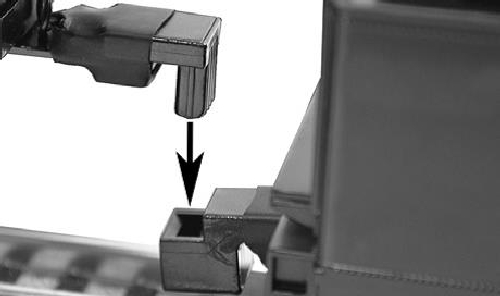

tender side of the connection (15th anniversary tender)

https://www.lionelsupport.com/...NDER-ONLY-1923031T01