1. I think I may have figured that out, it requires a little hand routing to make it work.

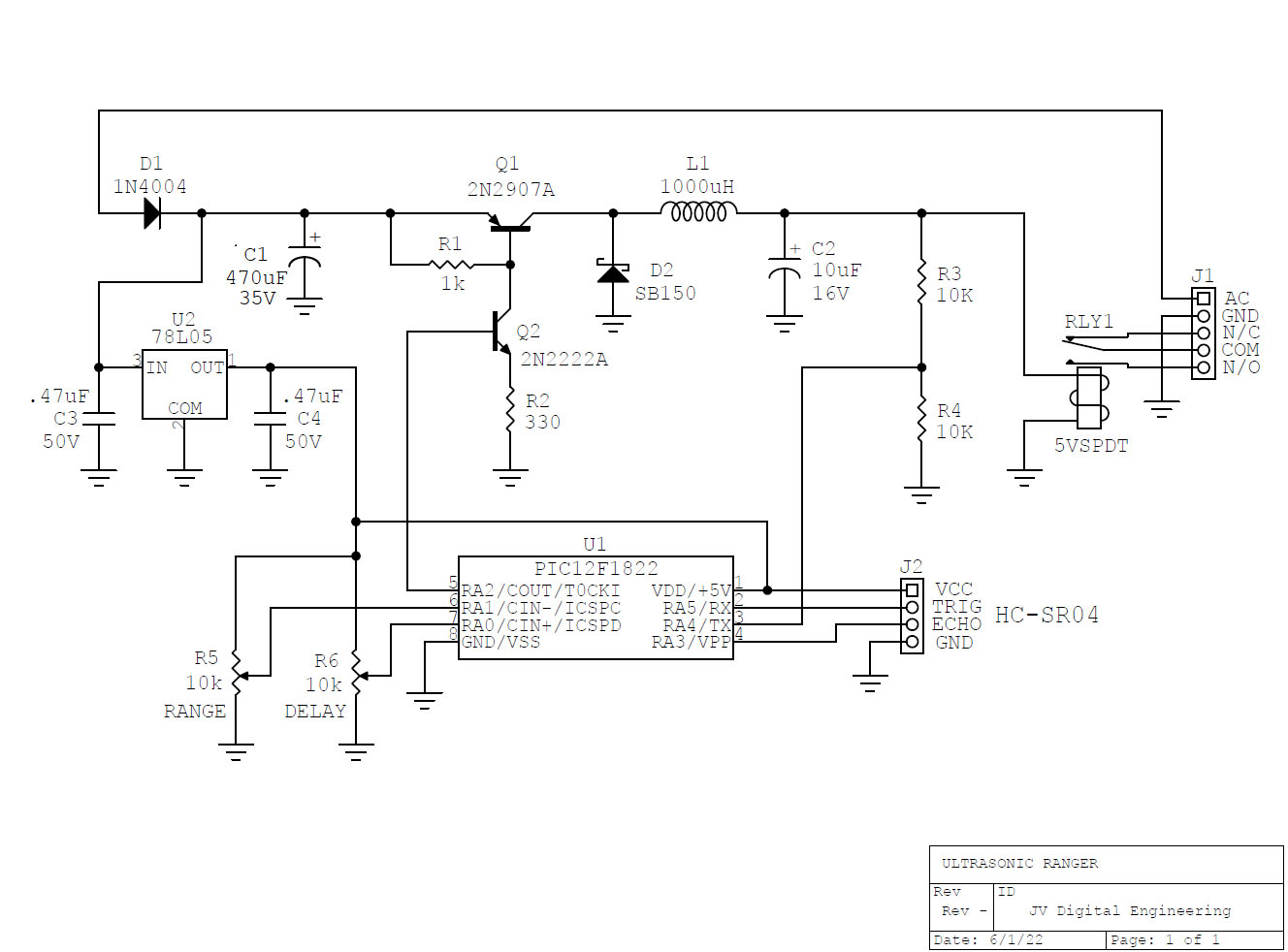

2. There's only two IC's, I had oriented them to facilitate routing, so I rotated one with no issues.

3. The 3362P is twice the price of the the 3306F I'm using.

4. With a heatsink, the 7805T does the trick. I just moved it to the edge of the board where it could easily accommodate a heatsink.

5. They're labeled on the back, not any room to put the labels on top.