I have several old All-Nation and earlier steam engines which I hope to re-power with can motors and DCC. I had hoped to get appropriate parts from the Babbit kits now owned by BTS. However, they seem to be a long way off, and I'm not getting any younger. Ques. Are the motors offered thru P&D Hobbies suitable? Who makes or can make suitable mounting and drive connections? Three of my engines are tender drive, so drive shaft connections are critical. The same questions apply to engine mounted motors. While I have done simaliar upgrades long ago in my HO days, I can't seem to find the right stuff or expertize in O. I would appreciate any useful suggestions. Yes, including professional re-builders. Many thanx, Dave Gould

Replies sorted oldest to newest

I can help. Will get back to you later. For now, I recommend NWSL P/N 653-6, Pittman 8x24, where x can be whatever they have in stock, and Toyota #0 hose. Motor attaches with a piece of inner tube and aircraft .032 safety wire. You can get the Pittman almost anywhere, from prices ranging from $25 to $200. Try Pittman first. Then Sunset.

Sdy Loco,

I have replaced several motors in All Nation steam locomotive models with new can motors. I have used Pittman and Sagami motors (no longer available) for this job. I usually coupled them to the original open worm and gear yoke that came with these models and they perform very smoothly. I machine a drive coupling from 3/8" brass bar stock turned with a collar to fit tightly inside standard 3/8" OD windshield washer hose which is fit between the brass ends. One brass end is bored to the motor shaft diameter, the other end fits the worm gear shaft. The brass coupling ends are locked onto the shafts with 1/8" long 6-32 allen head set screws. The turned shoulder on the brass rod should be about 0.210" in diameter to be a tight fit inside the rubber tubing. Length of the shoulders should be long enough to almost span the gap between the motor shaft end and the end of the worm shaft when the ends are installed in the drive line. Hose should be cut so there is a minimal length of unsupported hose. This allows for some misalignment but does allow the coupling to vibrate when the engine is running. Unmachined length of brass rod where the set screw goes can vary, 1/4" to 3/8" long usually works.

I have made quite a few of these couplings over the years for this type of upgrade and also for repowering brass models.

Anybody with a decent metal lathe and drill press can make these couplings and any auto part store will sell you some windshield washer hose.

Joe Foehrkolb

OOPS1. My previous post should have said DOES NOT ALLOW the coupling to vibrate.

Joe

Im not sure this will help, but if you have an older open frame motor Iv'e found that a couple of rare earth magnets stuck to the outside frame in line with the armature makes quite a difference. Stephen (cTr...Choose the Right)

Bob,

I have used the Toyota hose you recommend on a Lobaugh challenger mechanism for the connection between the front and rear driver sets and in that close clearance application going through the rear cylinder block it works fine. However, I got the idea for my couplings from copyiing a Central Locomotive Works coupling that came with a PRR H-10 kit I built back in the 1970s and find that, properly machined and installed, they are dead quiet and last forever. Just my way of doing things and I have never had a complaint about my drives using the windshield washer tubing. It is pretty tough stuff.

You can, as you say, sleeve the motor or gear shaft to accommodate a direct install of the tubing. I have done that and it also works. I just don't care for it that much.

Joe

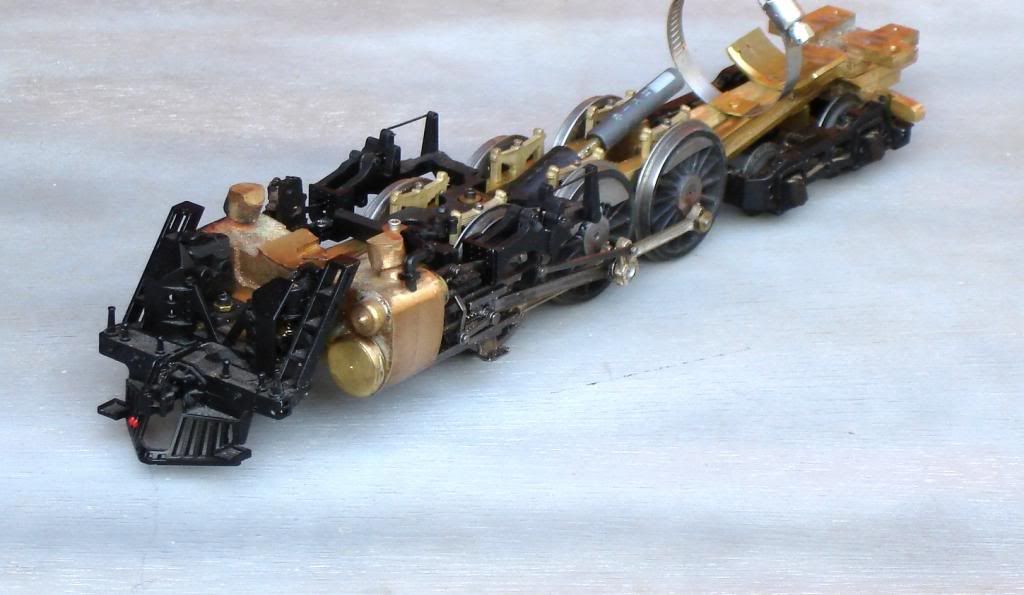

This one is a MM-2 Mallet Mogul. The rear gearbox is a 653-6, and the front is a 253-6, assuming the rear to be where the motor is.

This gives a non- synchronous appearance to rod angles.

I usually have limited space between engines for rubber tube, so I use speedometer cable with a slip-joint for all my articulated mechanisms. I think you can see it in there.

I guess not. Not important. This next one is a "Log-Mallet". Those are 54" drivers, and that is a tiny Escap motor. Tis is as small as you get in O Scale, and the big advantage of the NWSL shines here. You cannot see the driveshaft or gearboxes, and murtherfore you get to have a completely round boiler. No slots!

hello guys and gals........

Are PITTMAN motors still in business ? My Sunset 3rd S.F.Texan has the PITTMAN motor #9232 or is it 9233? can't remember which and it has the rare earth magnet in it. What is so special about the rare earth magnets that's used in some PITTMANs ? I think Sunset would sell you some low profile cog-belt drive system for the MM-2 mallet as their drive system is heavy duty from what I have seen in my S.F. Texan. Just a thought.

the woman who loves the S.F.5011,623

Tiffany

Bob

Is your logging mallet freelanced? Fifty four inch drivers are very large for a logging mallet. Only a few were built with drivers larger than 44 inches and those had piston valves.

I would love to see photos of the rest of these locomotives.

Yes, freelance. Yes, Pittman is still going strong, but it is no longer a model train endeavor. We are a pain in thir butt - they will sell you off the shelf motors. Sunset gets a quantity discount.

if you can do a direct drive, there is no need for a drop- down belt system. That is the beautynof the 8000 series motors.

My first models were all 9000-series, but when I tried th 8000, I never looked back.

and yes, rare earth magnets make a difference - almost twice the power or half the heat - your choice. I would not give a fig for a motor with a "1" in the third slot.

To bob2: Why do you choose Pittman 8000 motors over 9000? I don't know alot about these things, but Sunset put 8000 motors in their Jawn Henry also.

Robert,

The 9000 series that I have in a 2-8-0 is a HUGE, powerful, but very slow motor. My loco did a max 25 smph. The motor absolutely filled the firebox. Pulled at least 15 mixed brass and plastic cars up a curving 2% grade on 3 volts and so little amperage that the meter needle didn't move. Now, the prototype branch that the loco actually ran on had a speed limit of 25.

The 9000, IIRC, will not fit in a hood diesel. The 8000 gives a larger spped range and will fit in just about any loco.

ChipR

Thanks ChipR. Sunset uses the 9000s in its large steam locomotives. I have quite a few of them, but they can go faster than 25 scale miles per hour, although I don't run the giant articulateds much over 40 mph. I like to run them slowly to see all of the rod action.

All my early work uses the 9434. When I discovered the 8424, and compared its performance, and size, and speed, I never looked back. I am pleased with the 8000 even in the largest articulateds. Others have a different opinion - good thing, or all our models would be the same.

Thanks bob2. They 8000s are probably ideal for Southern Pacific's ACs because they were used in freight and in passenger service. The same would be true for Big Boys since they could go up to 80 mph. The Virginian 2-10-10-2 and the N&W Jawn Henry were much slower, perhaps the 9000s here? I would have to agree that from what I hear, the 8000s are the more versatile motors for any large engine.

Im not sure this will help, but if you have an older open frame motor Iv'e found that a couple of rare earth magnets stuck to the outside frame in line with the armature makes quite a difference. Stephen (cTr...Choose the Right)

Nice tip, never thought of that.

As you can see from the photos, having a driveline completely below the frame is important to me, as is having a round boiler. My first Mallet uses a CLW skewed armature open- frame motor, and the drive line is quite low. The giant AC-8 has a 9434, and the motor shaft is high enough to require a slot in the throat sheet, and a bend in the rubber hose. My AC-4 is just as big (17/64 scale) but has the much more satisfactory, to me, 8000 motor.

Hello guys and gals..........

Is the Pittman #9000 motors bigger in diameter than the #8000s ?

the woman who loves the S.F.5011,623

tiffany

Tiffany,

The 9000s are 40mm, 8000s are 30mm.

ChipR

For Tiffany and anybody else interested in the specifications on the Pittman 8000 and 9000 series motors:

http://www.robohobbies.com/datasheets/GM8224d204.pdf

8000 series lengths can be found on page 2. 8000 series diameters can be found on page 5.

9000 series lengths can be found on page 8, while 9000 series diameters can be found on page 12.

Keep in mind that these specs are for the gearmotor versions, without flywheels. This presumes all reduction is done in the gearmotor, and any other gears in the drive are 1:1. However, both the overall lengths L³ and the gearhead lengths L² are stated in the table, so simple subtraction would yield the length of any motor by itself.

I hope this helps.

Jim

I see ChipR beat me to it. If one prefers Imperial units, diameters are 1.580" to 1.175".

hello ChipR ..........

My Sunset 3rd S.F.5011 Texan came with the #9232 Pittman motor. I think the 9232 came with the rare earth magnets. What is special about the rare earth magnets in those motors ? This motor doesn't draw much power when running at scale 40 mph, it draws just 1 amp at 13 volts using the MTH Z4000. Is that good ?

the woman who loves the S.F.5011,623

Tiffany

To Tiffany:

The Santa Fe 2-10-4 is a brute! It is heavy and well built. It will most likely out pull all of Sunset's articulateds because of it's longer attached wheelbase, where as the articulateds have most of their weight on the rear drivers, and not much on the front drivers. This engine weighs as much as my DM&IR Yellowstone and a 9000 motor would suit it well. It has the room for 9000s. Be happy with it for in my book it is tops for brass imports.

Hello Robert Bradley jr.

Thank you so much for your kind words and this even made me love my S.F.Texan more ![]() .

.

the woman who loves the S.F. 5011,623

Tiffany

thank You All for your many and varied responses. I'm afraid I am way behind in your apparent expertize. I still need very basic direction. Is there, can some one direct me to, a professional expert for this kind of work? I am a retired rlwy conductor and active rail historian so I need help w/technical dos and donts. Thanx to all, Dave G.

To: Joe Foehrkolb, "rrjjf", You seem to be one of the modelers that have resolved many of the issues I am fumbling over. May I contact you directly/ Though retired, I don't expect anyone to do freebies. Please contact via e-mail. Dave G.

Joe is an excellent choice for professional work of this type. I sort of thought you were planning to do it yourself.

Joe is very reasonable, but do not expect to take a $300 locomotive and turn it into a masterpiece for cheap. Better to buy them fixed up the way you want than to pay somebody else to rebuild them, unless you have lots of bucks to spare.

Sdy Loco,

I do not have your email address and I don't know how to obtain it on this list. I have been doing minimal work for others this summer as I am finishing up some locomotive projects of my own. I will be probably be picking up work for September at the upcoming Strasburg O meet on August 10 and from others who have contacted me via email over this summer. I have a feeling I am going to be quite busy this Fall. My direct email address is in my ad that runs in O Scale Trains magazine under Baldwin Forge & Machine.

Joe Foehrkolb

![]() Thank you, all who participated in this thread.

Thank you, all who participated in this thread. ![]() A very interesting discussion. Especially in a "throw away" world. Mike

A very interesting discussion. Especially in a "throw away" world. Mike

Here's a link to Pittmans current catalog spec sheets.

http://www.pittman-motors.com/..._DC_Servo_Motors.pdf

8000 series start on page5 and 9000 series on page 14.

-Dean

Bob2, thanks for the unsolicited endorsement of Joe Foehrkolb. I do plan to work on the simpler? re-powers myself. But I have two engines that need new motors and the replacement of one or two drivers, as they short out on two rail DC. I suspect they were once outside third rail engines. I have carefully noted your (and others as well) suggestions and intend to get brave and try an older All Nation 4-6-0 that runs great; but I want to upgrade to a can motor so that I can use DCC. Thanks, SDY LOCO

On the outside third: if only a couple of drivers short, checkmwith an Ohmmeter. Often folks just reversed a few drivers for better pickup.

Also changing motors is child's play if you can see your way clear to use my safety wire trick. It is bulletproof, and angle can be controlled with wood cradles fitted with hand tools and fixed with Walthers Goo (dime store contact cement).

The A-N ten wheeler is a candidate for tender drive, although it is almost big enough for a motor in the cab.