Title says it, what do you guys use?

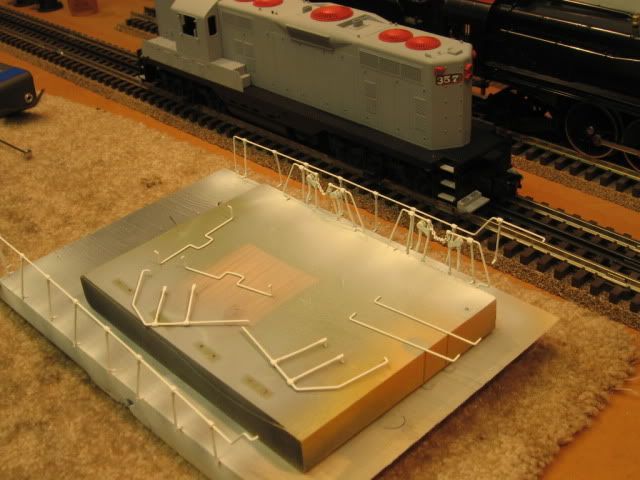

Seems like every time I have a spraying job I always have small parts like hatch covers, windshield wiper blades, and small screws. The blast coming from the airbrush is enough to move them around on the piece of cardboard box I usually use to sit stuff on to paint.

I've poked holes in the cardboard, I've used tweezers to try keeping them still, but nothing seems to be the best method. Seems like I always have to re-position them to get complete coverage, which usually ends up with more paint on the model than I would like.

Let's hear some ideas!

Also, anyone use 91% alcohol to thin acrylic paint? I'm using Model Master on this job and don't have any of their Universal Acrylic Thinner on hand, but I do have a quart of 91% alcohol and I've read where some folks use it (I Googled it and found things other than trains).