Hi folks

my wife and I are working on clearing space for an along the wall layout in our basement on a wall of about 28'. Figure to make a kind of out and back or dogbone with DC Union station represented at one end that would be like a 6'x6'. Couple of things that I don't know since I have been an HO modeler for many decades.

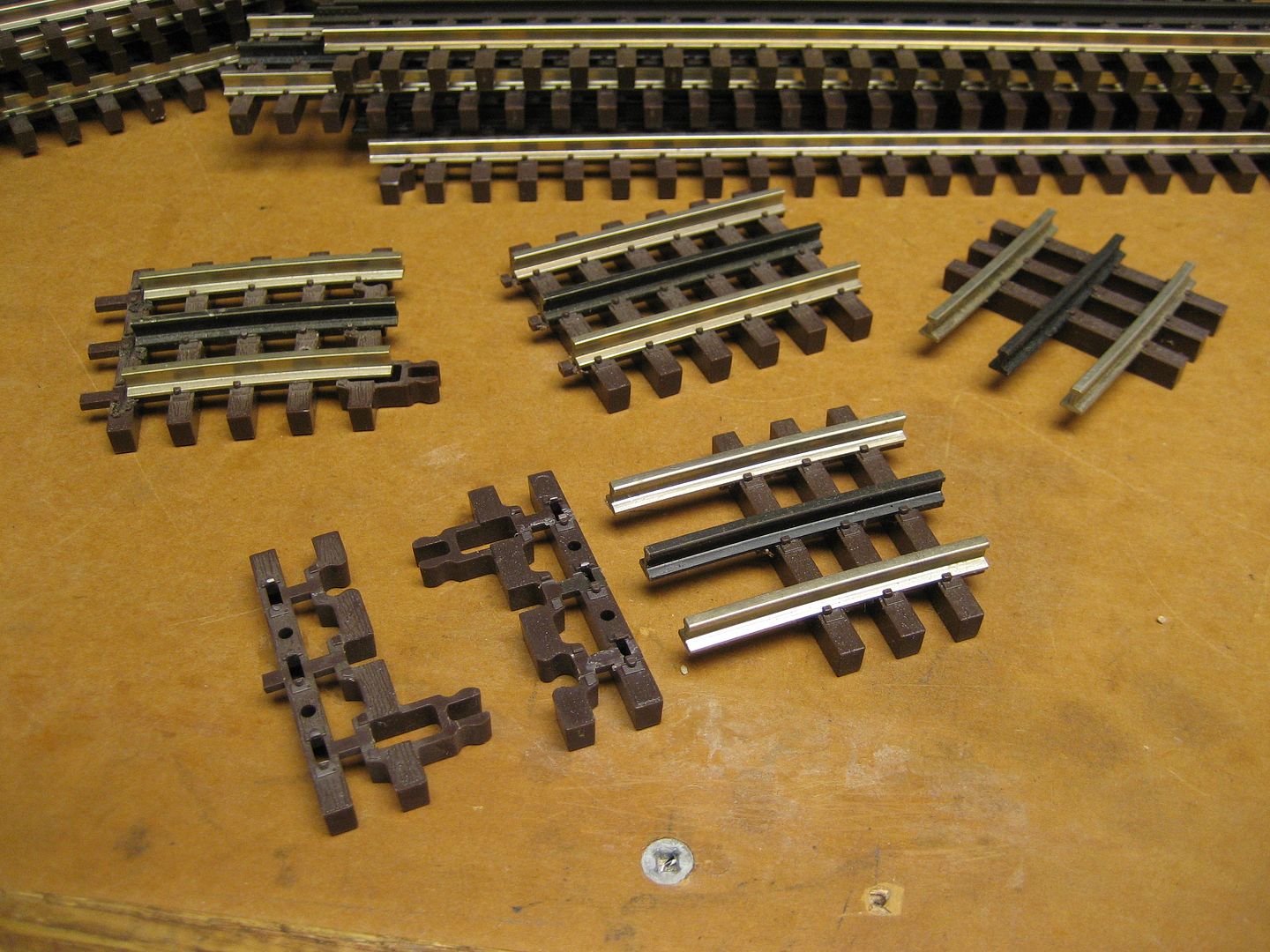

What track do you think will work best? I have some MTH real track that I would like to use (at least in part) and have bought some transitions/adapters to go to tubular track where and if needed. Using the track planning software like Anyrail or looking at CTT layouts shows me that I need custom lengths of straight track for just about any configuration like I would need for Union Station in miniature. That looks impossible with MTH Realtrax as I need like 4&1/8" sections as an example. Can I transition to Atlas track in the custom straight areas from tubular and is mth 3d generation tubular a candidate for transitioning? I have the Atlas transition kits as well. I am looking at Atlas just because of my HO experience but am open to suggestions.

For the along the wall segments that will be basically just two tracks and a possible siding or "interchange" in one of two spots how wide to you think would be good? For HO I would do 2'. Doubling that for O seem too much. 3' would waste like a foot of each 4'x8' bought so 2' would be nice but... What is the experience of those that have made along the wall sections?

What do you all use to cut solid rail or tubular? I use Xuron nippers for HO but I am not at all sure they would work with O gauge track.

Thanks is advance!!

Robbin