I have seen steam locomotive fireboxes with so many leaking staybolts that the firebox looked like a tropical rain forest.

Lots of leaking bolts could indeed "...cause a raining down of water..." in the firebox.

Rich,

Would that condition exist during operation or during a backshop inspection?

I would have to wonder the same. For the condition to exist like that, the problem would seem to lend itself to either fuel type.

I understand a fair amount of metallurgy and fatigue, etc, just trying to get a better grasp of steam power generation.

Also is there a common grade of steel used in this application both for the crown sheet and bolts or does it differ quite a bit? I would have to believe that it would at least be narrowed down to certain grades which lend themselves better to heating and cooling in the required temperature ranges.

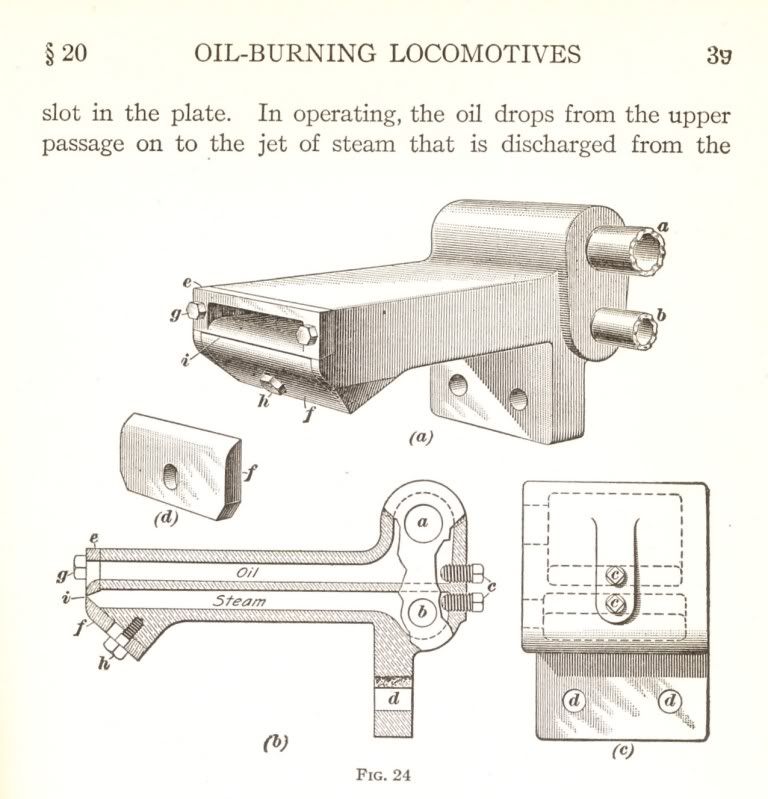

I guess what I am getting to is what exactly was the cause of this particular failure and/or these types in general. I am having a hard time grasping the raining down part due to the temperature of the water and the temperature inside the fire box itself. Is it really to such a degree as to put out the fire? How exactly is the oil burned, basically a pan or other apparatus?