Baldwin 4-6-0s were common on many shortlines throughout the South, and my favorite local one - the Virginia Blue Ridge Railway - was no exception. They purchased this one third-hand, from Georgia & Florida RR, built for the Augusta Southern:

I have a thing for small steam, so when I realized the WBB Ten-wheeler had almost identical overall dimensions, I knew what I had to do. Get one, strip it, cut, grind, and file off all the cast-in detail, and turn it into an almost brass-quality scale model. Here is the victim, looking handsome already:

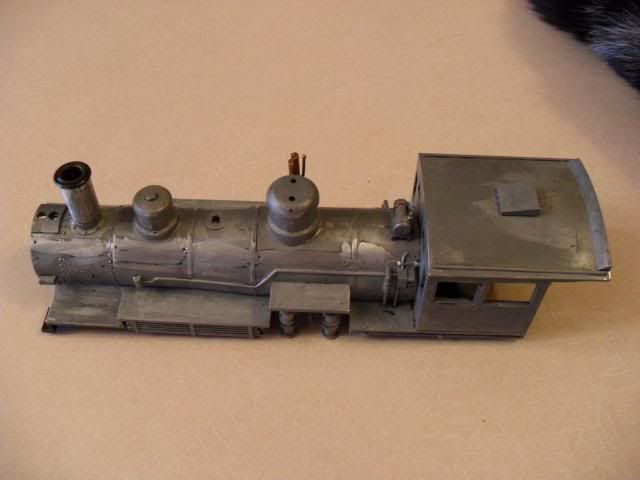

The first step was to remove all add-on details - headlight, stack, bell, whistle, pop valves, and generator. They're all going to be replaced by better-looking brass parts. This is how it looks after an initial disassembly:

I've begun to order detail parts, with more to come - from PCS, Stephenson, and Wiseman. It's going to get slide-valve cylinders, Walschaerts valve gear, and most everything else you see in the photo above. I expect this project to take several weeks, if not months, but I thought I'd get the thread started. I'll post, periodically, when I'm able to get some work done. Hope you enjoy watching the progress!

PS - If anybody has advice on the best way to remove cast-in piping, handrails, etc. without removing too much material or leaving visible marks/gouges, please post here!