For all of the touting of facts, we really have not heard anything about the gear ratios MTH puts in their diesels or their history.

Christopher

To date MTH has used 10.5/1 gearing in their diesels.

There have been several evolutionary steps in the development of MTH Diesel trucks. If you are interested in exploring that topic another thread might be appropriate. We are headed for page 3 here as it is!

MTH has contemplated changing their gear ratios. If I learn any more at York I will pass it along.

Sunset chose their drive train with smooth starts and slow speed operation in mind first and then applied the electronics. To me this is the way it should be.

After seeing and running the Sunset E7, Talking with Scott, reading Scott's posts and reading John Smith's old OST column I have a different take on how and why they were made.

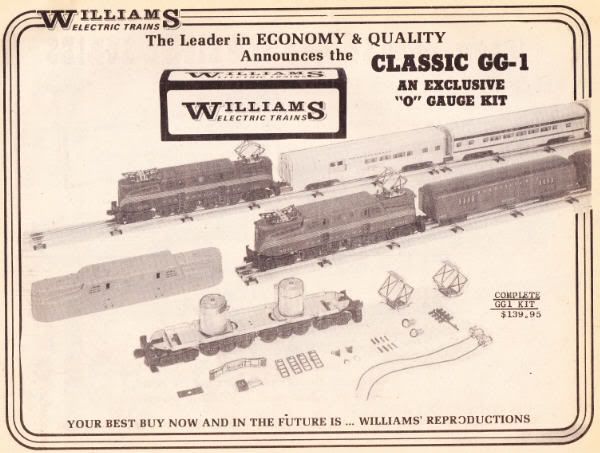

Certainly marketing plays into it as evidenced by the add behind the original post and

the "this is the way it should be" inclination of a segment of the market important to Sunet.

Cold economics may be the strongest driver. As I recall, Scott said this is the first Diesel produced by this manufacturer. Sunset is a small importer compared to Atlas, Lionel and MTH. The cost of the tooling to make a diecast truck block for a relatively small production run probably wouldn't pencil out. And the builder might not have the ability to make it without subcontracting the work out. Sunset's construction method might not make sense for trucks that were made by the thousands but it can keep a small run priced only a little higher than locomotives produced in larger volume.

I think Lionel may earn the China drive title along with the others Ted wants to blame for the bad reputation.

Take a look at the post about the Lionel locomotive again.

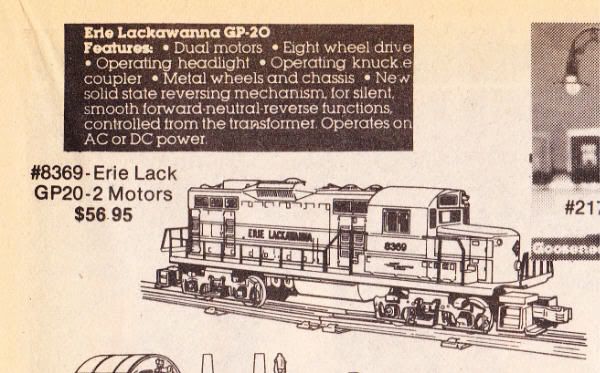

By 1983 Lionel was making diesels with horizontal mount in truck DC can motors (like the K-Line MP-15s and Alcos.) These were dual motor units with an electronic e-unit.

Those were tiny horizontally mounted motors without a flywheel mounted inside a plastic truck.

I think Norm and KMK are on the right track. If we want a historically accurate geographically based name Maryland Drive is the leading contender.

By the way, do you guys know who coined the term China drive? I think it was Ed Reutler who seemed to stick it to Atlas from time to time. I don't think the term was born with any origin in time in mind at all of when the drive was developed, but rather the origin of the country where many of those drives were coming from when the term was coined.

Atlas seems to keep coming up in this discussion. I have had a chance to operate several of their RS-1s. They just don't run as well as an MTH Premier Geep or Railking RS-3. I have yet to see an MTH diesel that wont run smoothly at 4 SMPH and most will run smoothly at 2-3 SMPH. My experience with other Atlas Diesels is limited but I have seen comments on different threads about other models of Atlas Diesels not being smooth starters.

Williams, the orphaned Custom Trains FMs and all the first MTH diesels had twin vertical can motor drives in the early 1990s. They are rugged and run well. I have run several early MTH Diesels that have been converted to Proto2 and they run just as well as the diesels built with Proto2 a few years later. MTH made many of their early diesels in two rail versions so they were in the hands of two railers in the 90s. But the derisive attitude towards twin vertical can motor drives keeps getting linked to later entries into the then emerging 2 and 3 rail scale market. It sure would be nice to do a side by side operational test and mechanical tear down and see how things really compare.