I have a couple of Atlas switches that in one direction they do not completely move against the outside rail, about a 1/4 of an inch. I have looked inside the switch machine and there appears to be no way to extend the throw linkage. Is there any way that I do not see to make them throw all the way or do I need to replace the switches?

Replies sorted oldest to newest

What happens when you operate them by hand with the lever ion the switch machine? Do they travel all the way? If they travel all the way by hand, and work freely, you should be able to get them going reliably again. Check the throw bars and linkages and the throw bar springs. I got parts from Atlas and replaced throw bars, throw bar linkages and springs in some of them. The springs are adjustable via the linkages as well. If you are using less than 18 volts on the switches, you might also try increasing the voltage. I am using 18 volts on mine.

I have replaced some switch machines on some used switches I purchased. The old ones just seemed weak and would not throw all the way even with 18 volts. I also replaced the #56 switch controllers on some. those didn't seem to be functioning well either. The new switch machines come with a new controller.

I have been fiddling with the old left over switch machines that I replaced using DC voltage, they seem to operate much better on DC. Hard to tell they are bad this way? I haven't tried putting one back on a layout switch and using DC to see how well it works when hooked up to a layout switch that's in use. I have been thinking about changing them all to DC operation, but I don't have a suitable DC power supply, so that hasn't not yet happened.

Thank-you for the responses. I probably will not get back to the train room until Monday. I am pretty sure that they are not binding since I can freely move the points the remaining distance. On Monday I will electrically hook them up and see if powering them makes any difference. When I took the switch machine apart I noticed the spring referred to. I think I see how to adjust it. But, what exactly does changing the tension actually do?

The spring holds the switch points to the rail they are switched to, but it allows a train to pass through the from the opposite position of the switch and lets the switch points spring back to the rail they are switched to after the train passes. Anti-derail feature. My wording wasn't too good here, I'm not good at explaining things in the written text sometimes. Hope that makes at least some sense.

With some of the used switches I have, I just had to fiddle with them and try to see why they were not working well. It took some trial and error fiddling too, but I have them all working now, except for the one that the rails came off of. ![]()

I have not tried the capacitor discharge method Dale H mentions, but that is also a good way to switch them and adds protection so you don't burn them up by holding the button down too long. A common problem with all twin coil switch machines, not just Atlas.

The mechanical non-de-rail feature may need adjusted. Each switch has a spring loaded V-shaped tension device. You can adjust the spring tension by moving the small pin to a different hole location.

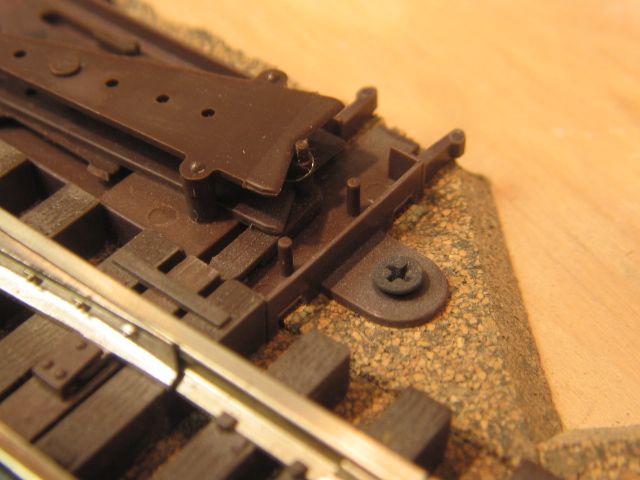

Note the center position of the spring and throw bar in the V for full throw.

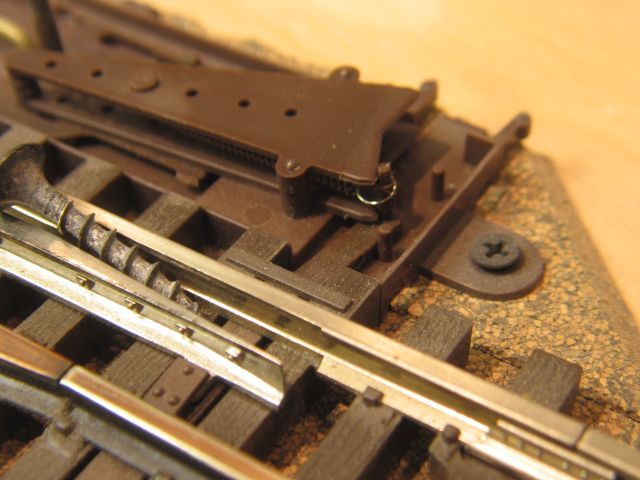

Note when the switch is held open,(By the drywall screw), in a non-de-rail alignment, to allow wheel flanges to pass through, switch in the wrong position. Note the position of the spring and throw bar to the left of the V, Switch not closed.

If you move the small brown pin back, increasing spring length and tension, two things happen, Mechanical Non-de-rail is much harder and may not work properly, but there is a good chance the switch will throw completely.

Also note that Atlas switches need to be installed level, perfectly level. Sometimes just loosening mounting screws will free the switch enough to work well.