I am having a bit of trouble visualizing and trying to determine how to make an effective track joint between my modules. I have scoured the internet and have seen the peg and hole method, the Lionel clasp method and others. I want to go with the Harbor Freight method. Cheap clamps.

I have already tested this and it is strong and sturdy. I have not laid any track as of yet. The reason is I cannot determine how to join the tracks. I would prefer not to use mating tracks as lining up the pins and pushing two tables together would likely result in frustration and bent pins.

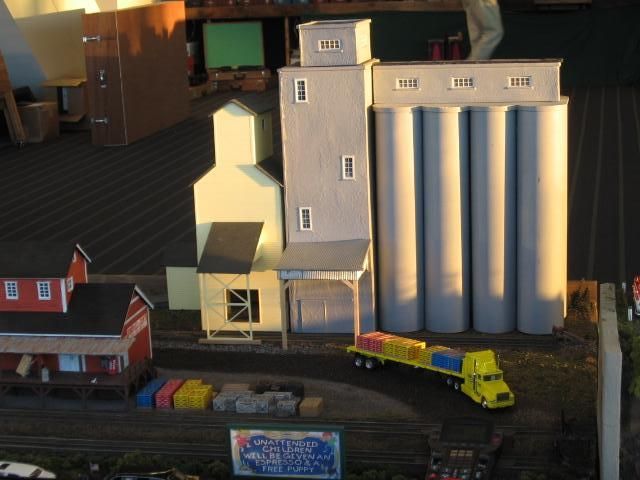

My preferred method would be a pin less mating of the tables and then power traversing the tables. Given this I have some curves going over the table joints. To cut the curves would mean removing ties out of my Ross tracks I suppose.

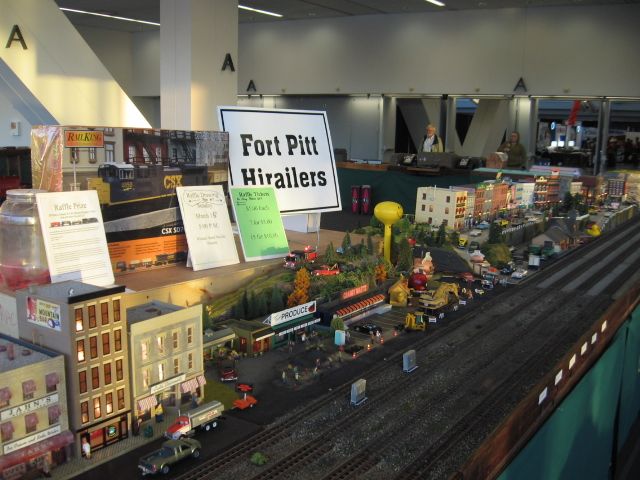

Below are some pictures to help illustrate where I am at. Any tricks or techniques to ensure a non-derailing joint? I feel that this cannot be that hard and that I might be missing something. Wouldn’t be the first time J