I need some good opinions on cutting down the size of my layout. After 15 years I have decided to remove the one side that is against the wall. I need to cut length 20' long. I want to be able to walk around all of the layout. I need to cut through 5/8" plywood, 1/2" homesite, plus the framework 2x4's. I want the cleanest way possible. I have the room full of trains and buildings that I don't want to clean afterwards. Let's hear your suggestions. Thanks Dave

Replies sorted oldest to newest

Hey Dave. Well....if you are cutting wood, it is going to take a saw. I would use a combination of circular, jig and reciprocating saws. I would have a helper use 1 or 2 shop vacs with a nylon over the exhaust vent to control the dust from being blown into the air. Any saw dust that still occurs should drop down to the floor where if can be cleaned up. I would think this approach should keep dirt to a minimum.

Go slow and cut straight lines to avoid excessive sanding later.

Regardless, unless you have access to a laser, you will get some saw dust to deal with.

Donald

I think you have a dust problem. Cutting Homasote with a saw makes a huge amount of dust and it has to be a saw to cut the plywood beneath. A circular saw with a vacuum cleaner hose attached would help but there will still be dust.

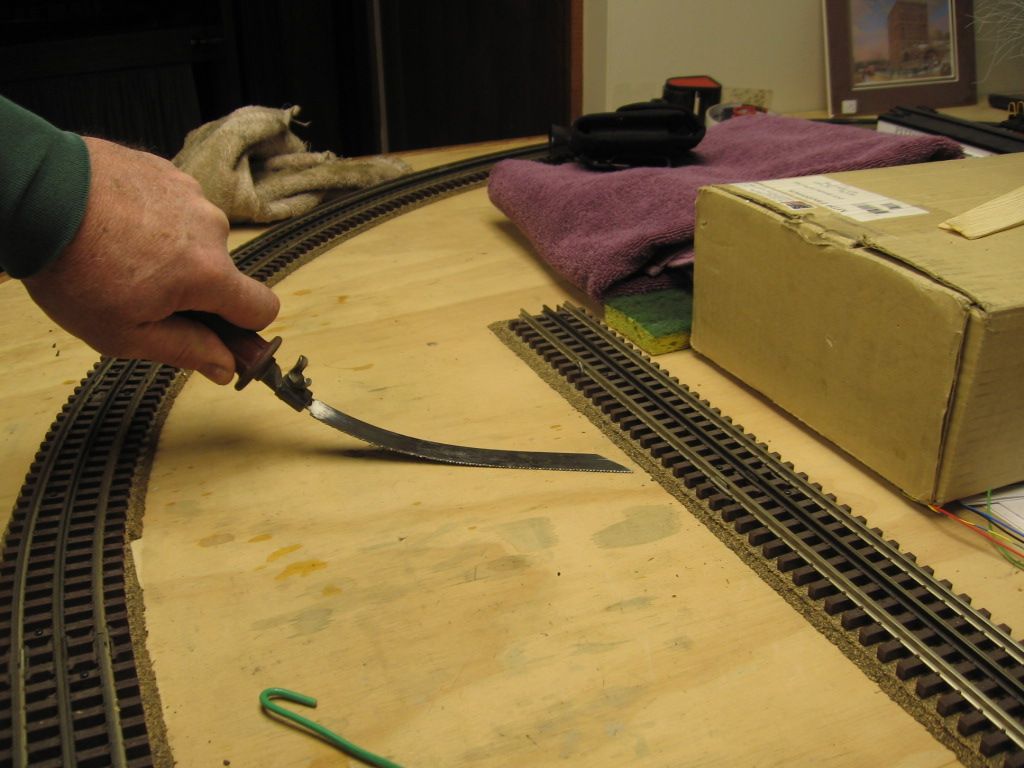

To cut the 2X4 framing in place I think you will need to use a sawzall to have sufficient reach. Again, lots of dust.

If you must do this, it sounds like maybe temporarily taping plastic sheets from the floor to the ceiling in the area you are working may be a way to prevent dust from spreading excessively throughout the rest of the train room.

-Dave

Chainsaw? ![]()

I'd just get out my sawzall and get right after it.......but the dust would be unbelievable with that Homasote.

Done this more than once. In fact just did one of these in July. A new fine tooth hardened tip circular saw blade with an attached clean hepa filtered vacuum on top and a helper following below with a hepa filter shop vac. I also use Delta air cleaners on a dolly to follow the work.

Of course, before you start, place temporary supports on involved cross members to maintain structural integrity at what will be the new platform edge. Carefully align a level horizon on the raw edge. Then, with fresh STRAIGHT material, apply a well supported new side rails

Depending on how delicate your layout decorations are, consider using light weight poly 1 mill paint drop cloths.

I saw Homasote indoors on a somewhat regular basis in customers homes with nary a complaint. I can not stress enough the need to have a freshly cleaned hepa filter and a new saw blade.

Once you have run the slit then follow up with a SawsAll to complete cuts in the cross members.

You could use a quality Bosch jig saw however the edge will not be as straight as a circular saw would provide. The most irregular cut would be one cut with a reciprocating saw.

If you skip any one step in the above you potentially can have a mess.

In any event, cutting a 1 1/8" dado to accommodate the 5/8" plywood and the 1/2" Homasote along the inside top edge of the new side member would clean up the cut. Follow up by cutting any involved crossmembers back equal to the depth of the dado.

If you have 3 1/2" frame members on the rest of the layout use a custom 4 5/8" ripped new side member to share a common lower edge.

Thanks for your suggestions. They are helpful. Dave

Since it sounds like you are going to remove the section closest to the wall, regardless of the saw you choose to use, you may want to get a very straight length of, say, 1’x2’ which you could screw to the existing top surface of the benchwork, giving you a straight edge to run the saw against, helping to keep the cut straight.

John's chain saw is an interesting idea. May be a little less intense. An assortment of different blades, one that I have used successfully is a reverse cut/ cuts down and into the material, with limited splitter-ing of the surface. Variable speed is nice.

Dirt, dust, debris is a constant remodel concern. Customer education about the process helps. Comment at the end of the day. If dirt, dust is the problem, it's been a very good day. IMO, Mike CT.

Edit/Add: Remove nails use an old hand saw. 10/26/20 AM.

Nursing homes/hospitals use positive ventilation systems, with hepa-filters, to contain construction dust. You would also see this type of equipment, and containment, on a site where asbestos is being removed. Can become a matter of how much money you wish to spend.

@Tom Tee posted:Done this more than once. In fact just did one of these in July. A new fine tooth hardened tip circular saw blade with an attached clean hepa filtered vacuum on top and a helper following below with a hepa filter shop vac. I also use Delta air cleaners on a dolly to follow the work.

Tom's the king of doing this kind of work with minimal mess, I was impressed how little debris we generated cutting wood and Homasote. ![]()

Good ideas. Along the lines of the chain saw, I have access to a road saw. You have to use water, that takes care of the dust problem.

John, that was a joke. Don't try that!

How much water do you have to use? ![]()

Any amount is to much

I did surgery on my layout when I cut it apart to reconfigure the track plan. I used the sawzal with a fine tooth blade.

Hey Dave Nichols...try contacting Pat Halpin of TCA Western Division ( I think). I remember talking to him a few years back about how he cut up a large layout. Might have advice...like plan twice...best 2 U!!

Rich883, it does seem the slower the saw the less dust and mess?

When we remove broken tile in a residence, we cut a hole in the side of a cardboard box to tightly fit the shop vac hose, cut a small rectangle in box to see jackhammer bit and hammer away. Dustless removal. You can do same with variable jigsaw. Use a guide and cut slow. Use cheesecloth over the vac exhaust.

You should determine if you will be cutting though nail or screws. If so a cutoff saw with a metal cutting blade may have to be used to cut those sections.

Charlie

Good point Charlie

@Dave Nichols posted:Rich883, it does seem the slower the saw the less dust and mess?

Dave,

same amount but it did not fly as far when I went slower.

No mention yet how to best cut the track for easy re assemble?

If cutting the track is needed I would use my dremel tool with the heavy duty cut off blades. Have used it quite a bit on Gargraves and Lionel tubular. Thanks, Dave

HO track is pretty frail. How to do the least damage? The fella I was asked to help with this is new to trains and I don't know him at all. We're meeting at the house for the first time at 2 today. Will probably use a Dremel that I saw there the other day. A realtor friend asked to to advise them on this removal as the house was just recently sold. Layout has been sitting for several years since the owner passed. Wish I had met the builder some years ago as the layout is fairly large and themed on the Santa Fe.

When I heard what needed to be done, I thought of a RotoZip or Zip Saw right away. I don't have one of these, but perhaps someone else does and they can comment how well a zip saw would handle the layout cutting task. The ability to have a drill-bit like cutting blade and be able to cut in any direction seems like it would be a big plus.

Dale